Laser beam splitting device and laser welding method

A laser beam and laser technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complicated operation, high labor cost, and uneven weld seam, so as to avoid uneven weld seam and welding shape Poor, save labor cost and time cost, improve the effect of laser welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

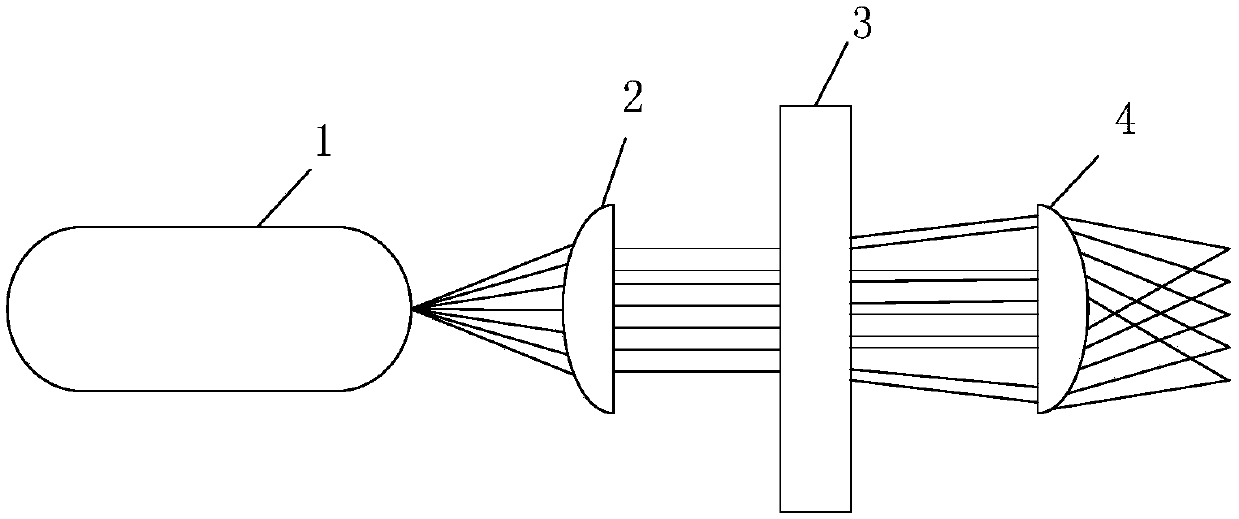

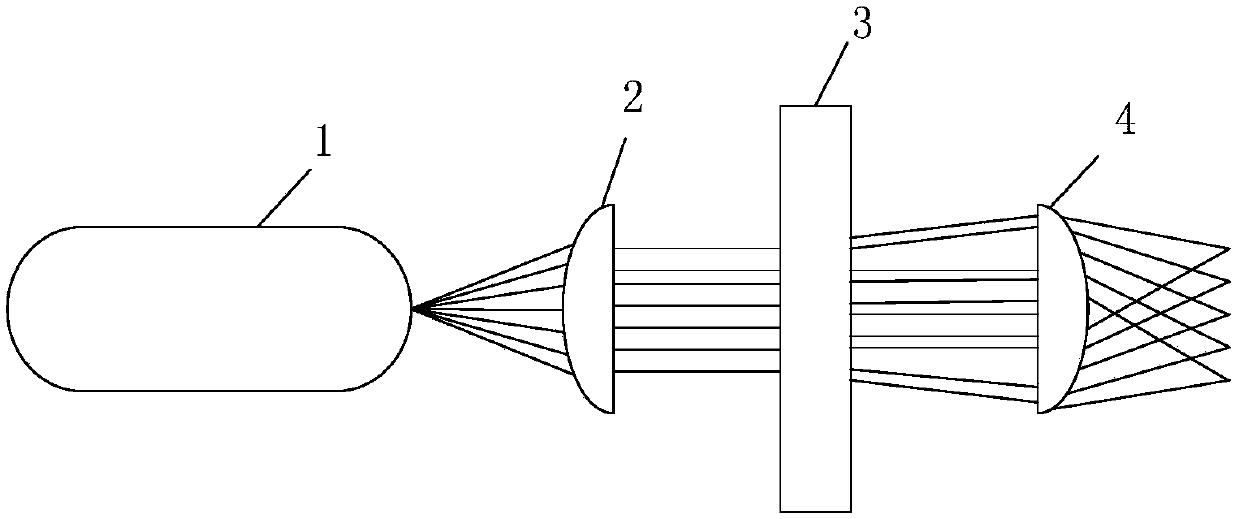

[0023] like figure 1 As shown, a laser beam splitting device includes: a laser generator 1, a collimator 2, a beam splitter 3 and a focusing lens 4; the laser generator 1 is used to emit a first laser beam; the collimator 2, for collimating the first laser beam to form a parallel second laser beam; the beam splitter 3, for splitting the second laser beam to form multiple laser beams ; the focusing lens 4 is used to focus the multiple laser beams to form a plurality of focusing points for welding; wherein, the collimator 2 is located between the laser generator 1 and the Between one side of the beam splitter 3 , the focusing lens 4 is located outside the other side of the beam splitter 3 and is aligned with the beam splitter 3 .

[0024] In the embodiment of the present invention, a first laser beam is emitted, the first laser beam is collimated to form a parallel second laser beam, and the second laser beam is split to form multiple laser beams. A plurality of laser beams ar...

Embodiment 2

[0031] A laser welding method according to the present invention comprises the following steps:

[0032] A plurality of semiconductors are pasted on the carrier with epoxy resin;

[0033] placing the solder balls between the corresponding soldering parts of the semiconductor and the corresponding soldering parts of the carrier;

[0034] emitting a first laser beam, collimating the first laser beam to form a parallel second laser beam, splitting the second laser beam to form multiple laser beams, and aligning the multiple laser beams Focusing is performed to correspondingly form a plurality of focusing points focused on the corresponding solder balls until the solder balls are melted.

[0035] In the embodiment of the present invention, a first laser beam is emitted, the first laser beam is collimated to form a parallel second laser beam, and the second laser beam is split to form multiple laser beams. A plurality of laser beams are focused to form a plurality of focal points...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com