Method for improving Mn alloy yield in semisteel steel-making

A medium carbon ferromanganese alloy and ton steel technology is applied in the field of improving the yield of Mn alloy in semi-steel making, and can solve the problems of high oxygen activity at the end point, low yield of Mn alloy in tapping, and the like, so that the yield of the alloy can be achieved. The effect of increasing the rate and reducing the oxygen activity at the end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The 37Mn2 steel is smelted by using molten iron after desulfurization and vanadium extraction as a raw material, and the Mn requirement of the finished steel type is 1.3-1.55% by weight.

[0022] In the present embodiment, the active lime is the active lime containing 90% by weight of CaO; the high magnesium lime is the high magnesium lime containing 30% by weight of MgO and 55% by weight of CaO; Ferrosilicon of Si and 25% by weight of Fe; the medium-carbon ferromanganese alloy is a medium-carbon ferromanganese alloy containing 80% by weight of Mn and 1.2% by weight of C.

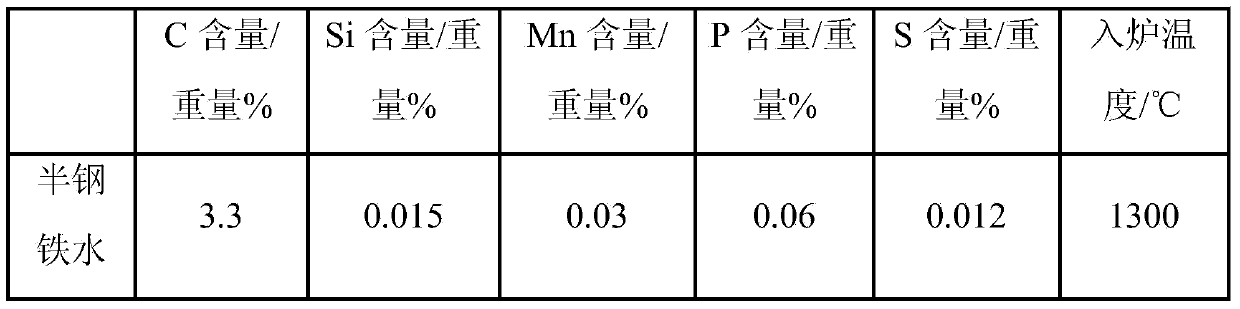

[0023] The nominal capacity of the steelmaking converter is 120t. The composition and temperature of molten iron and steel entering the furnace are shown in Table 1.

[0024] Table 1

[0025]

[0026] After blending semi-steel into the converter, add 5kg / ton of ferrosilicon steel, then add active lime, high magnesium lime in turn, and then blow oxygen with oxygen lance to carry out converter sme...

Embodiment 2

[0029] The 37Mn2 steel is smelted by using molten iron after desulfurization and vanadium extraction as a raw material, and the Mn requirement of the finished steel type is 1.3-1.55% by weight.

[0030] In the present embodiment, the active lime is the active lime containing 85% by weight of CaO; the high magnesium lime is the high magnesium lime containing 40% by weight of MgO and 48% by weight of CaO; Ferrosilicon of Si and 25% by weight of Fe; the medium-carbon ferromanganese alloy is a medium-carbon ferromanganese alloy containing 80% by weight of Mn and 1.2% by weight of C.

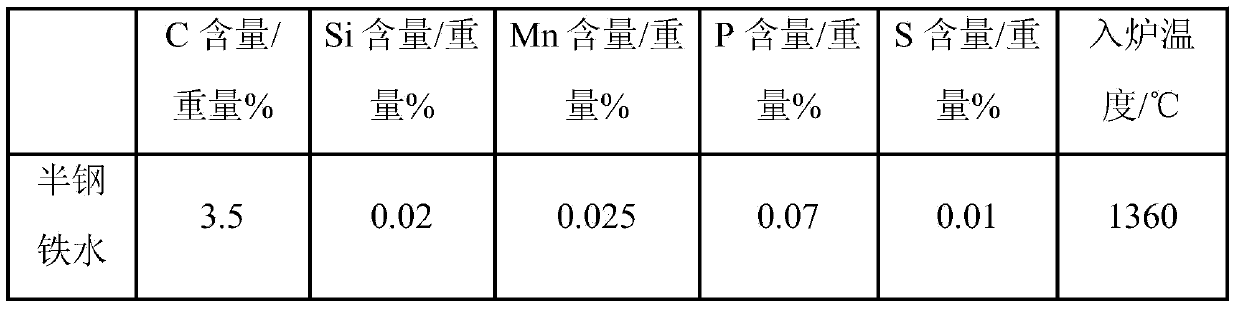

[0031] The nominal capacity of the steelmaking converter is 120t. The composition and temperature of molten steel in the furnace are shown in Table 2.

[0032] Table 2

[0033]

[0034]Add semi-steel into the converter and add 4kg / ton of steel ferrosilicon, then add active lime, high magnesium lime and then oxygen lance blowing oxygen to carry out converter smelting, wherein, the amount of activ...

Embodiment 3

[0037] The 37Mn2 steel is smelted by using molten iron after desulfurization and vanadium extraction as a raw material, and the Mn requirement of the finished steel type is 1.3-1.55% by weight.

[0038] In the present embodiment, the active lime is the active lime containing 87% by weight of CaO; the high magnesium lime is the high magnesium lime containing 35% by weight of MgO and 50% by weight of CaO; Ferrosilicon of Si and 25% by weight of Fe; the medium-carbon ferromanganese alloy is a medium-carbon ferromanganese alloy containing 80% by weight of Mn and 1.2% by weight of C.

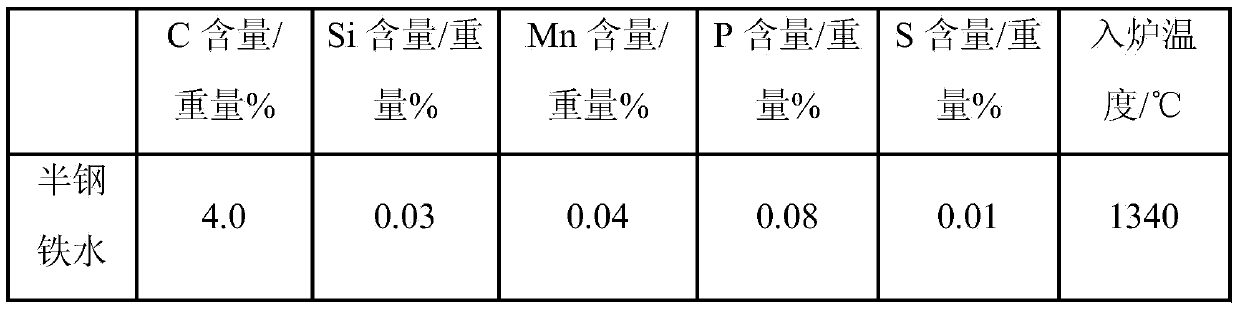

[0039] The nominal capacity of the steelmaking converter is 120t. The composition and temperature of molten iron and steel entering the furnace are shown in Table 3.

[0040] table 3

[0041]

[0042] Add semi-steel into the converter and add 6kg / ton of steel ferrosilicon, then add active lime, high magnesium lime in turn, and then oxygen lance blowing oxygen to carry out converter smelting. Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com