Flat plate rammer compactor and construction technology for ramming concrete of roller-compacted concrete gravity dam

A technology of roller compacted concrete and tamping machine, which is applied in the treatment of gravity dams, dams, and building materials, and can solve problems such as the inability to roll compacted concrete in roller compacted construction, so as to reduce the amount of pouring work, reduce the failure rate, and have small working resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

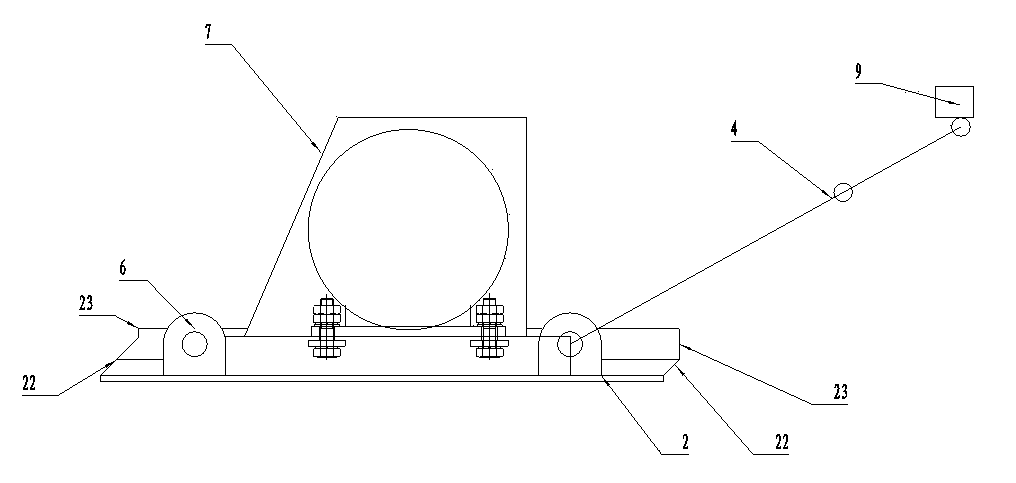

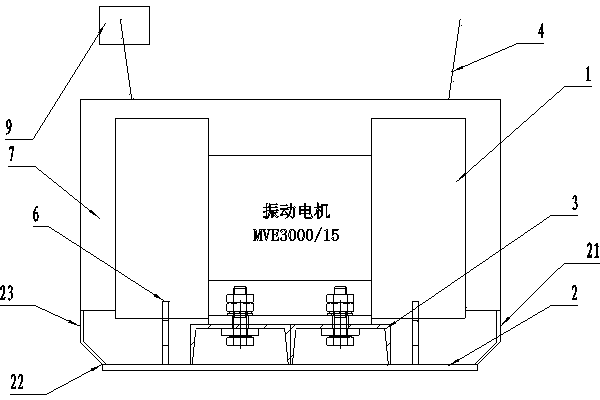

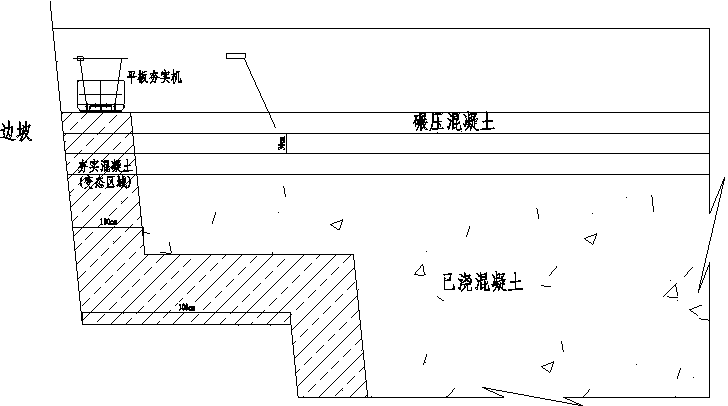

[0028] Example 1, such as Figure 1-2 As shown, a flat compacting machine is mainly composed of a vibration motor 1, a tamping plate 2, a base 3, a handrail 4, a protective cover 5, and a control switch 9. The tamping plate 2 is fixed under the base 3, and the vibration motor 1 is fixed Above the base 3, a protective cover 5 is fixed outside the vibration motor 1, the handrail 4 is outside the protective cover 5, and the size of the tamper plate is 80~100×50~70cm. In this embodiment, the size of the tamper plate is selected to be 90 cm×60 cm. A surrounding edge 21 is fixed around the ramming plate 2, and the surrounding edge 21 is composed of an inclined surface 22 and a vertical surface 23. The fuselage is inwardly inclined, and the inclined plane 22 forms an acute angle with the tamping plate 2, and the acute angle is less than 53°. The inclined planes 22 of the surrounding edges 21 on the other three sides are inclined to the outside of the fuselage, and the inclined plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com