Buffered weldless pick-shaped cutter for coal mining machine

A technology without welding and shearer, applied in cutting machinery, earth drilling, cutting machinery, etc., can solve the problems of short working life, fatigue, low mechanical strength of welding parts, etc., and achieve the effect of eliminating hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

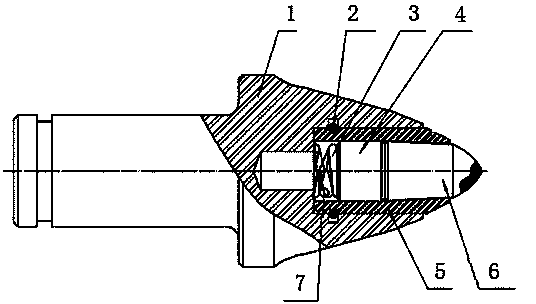

[0013] Such as figure 1 As shown, the buffer type non-welding pick pick for coal shearer of the present invention includes a tooth body 1, and the front section of the tooth body 1 is approximately conical. A blind hole 7 is processed in the center of the front end of the tooth body 1 , and a protective cover 5 is installed in the blind hole 7 , and the outer diameter of the protective cover 5 matches the diameter of the blind hole 7 . An annular groove is processed on the outer circle of the inner section of the protective sleeve 5 and the inner circle of the inner section of the blind hole 7, and a circlip 2 for axially locking the protective sleeve 5 is installed in the annular groove. The protective sleeve 5 and the blind hole 7 are fixedly fitted in the axial direction. Between the inner end and the outer end of the protective cover 5, a spring 3, a spacer 4 and a hard alloy cutter head 6 are sequentially arranged. The outer end of the hard alloy cutter head 6 is approxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com