Joint sealing structure for ductile cast iron pipes

A technology of ductile iron pipe and sealing structure, which is applied in the field of interface sealing structure of ductile iron pipe, can solve the problems of affecting the safety and stability of sealing, poor sealing effect, hardness difference, etc. The sealing effect and the effect of improving the quality of the apron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

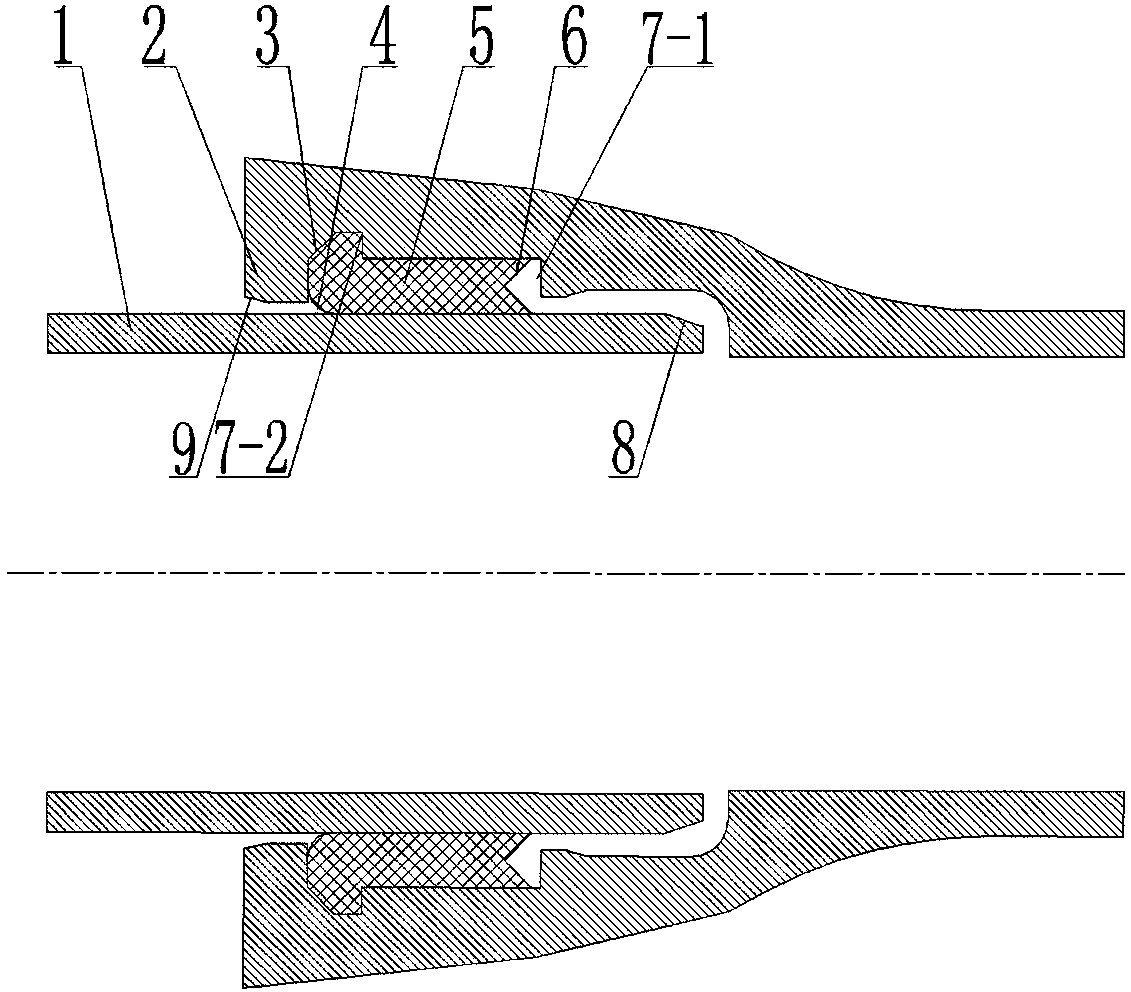

[0011] Such as figure 1 The sealing structure of the socket of the ductile iron pipe shown includes the ductile iron pipe socket 1, the ductile iron pipe socket 2, and the sealing rubber ring 5, and the inner surface of the ductile iron pipe socket 2 has an annular first groove 7-1 , the sealing rubber ring 5 is embedded in the first groove 7-1 and the thickness of the sealing rubber ring 5 is greater than the depth of the first groove 7-1, the outer surface of the sealing rubber ring 5 has a protrusion, and the first The surface of the groove 7-1 has a second groove 7-2 that matches the protrusion on the outer surface of the sealing rubber ring 5, and the contact surface of the sealing rubber ring 5 with water in the pipeline is V Type concave 6.

[0012] The sealing rubber ring 5 is embedded in the first groove 7-1. For the convenience of installation, the outer surface and the inner surface of the other side opposite to the V-shaped concave surface 6 of the sealing rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com