Multi-array planar heat tube

A multi-array and planar technology, applied in the field of heat transfer tubes, can solve problems such as insufficient heat exchange contact area, poor temperature uniformity, and poor overall heat transfer performance, so as to improve thermal management performance, improve photovoltaic power generation efficiency, and reduce The effect of thermal resistance

Inactive Publication Date: 2014-08-27

新疆品源太阳能科技开发有限责任公司

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to solve the problems of poor temperature uniformity on the outer plane of the planar heat pipe, insufficient contact area for heat exchange, and poor overall heat transfer performance in LED light source heat dissipation, solar hot water, solar photovoltaic and heat collection composite systems, the present invention provides a A multi-array planar heat pipe that can significantly improve the heat transfer performance of heat pipes in such applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

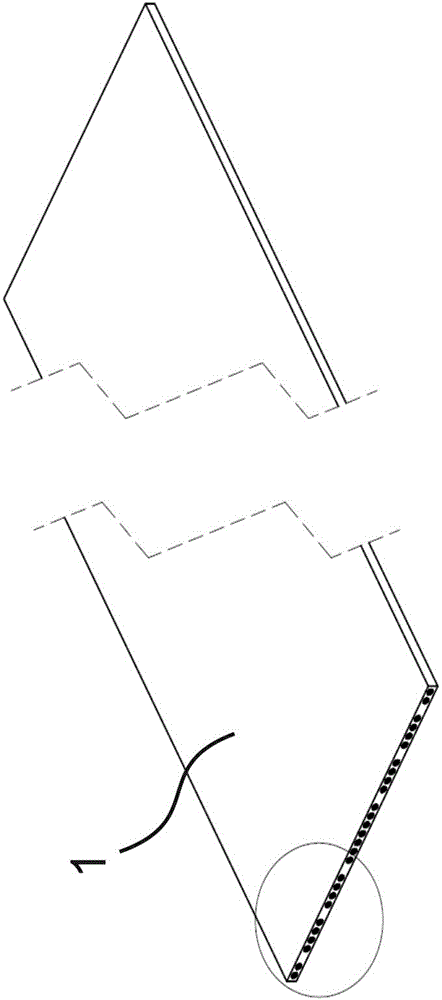

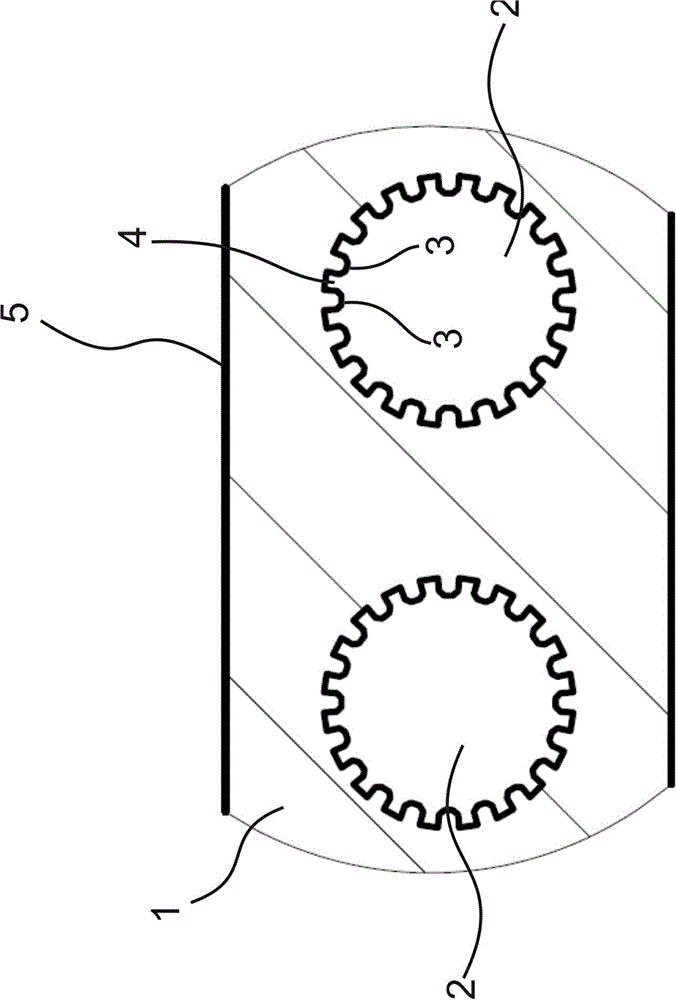

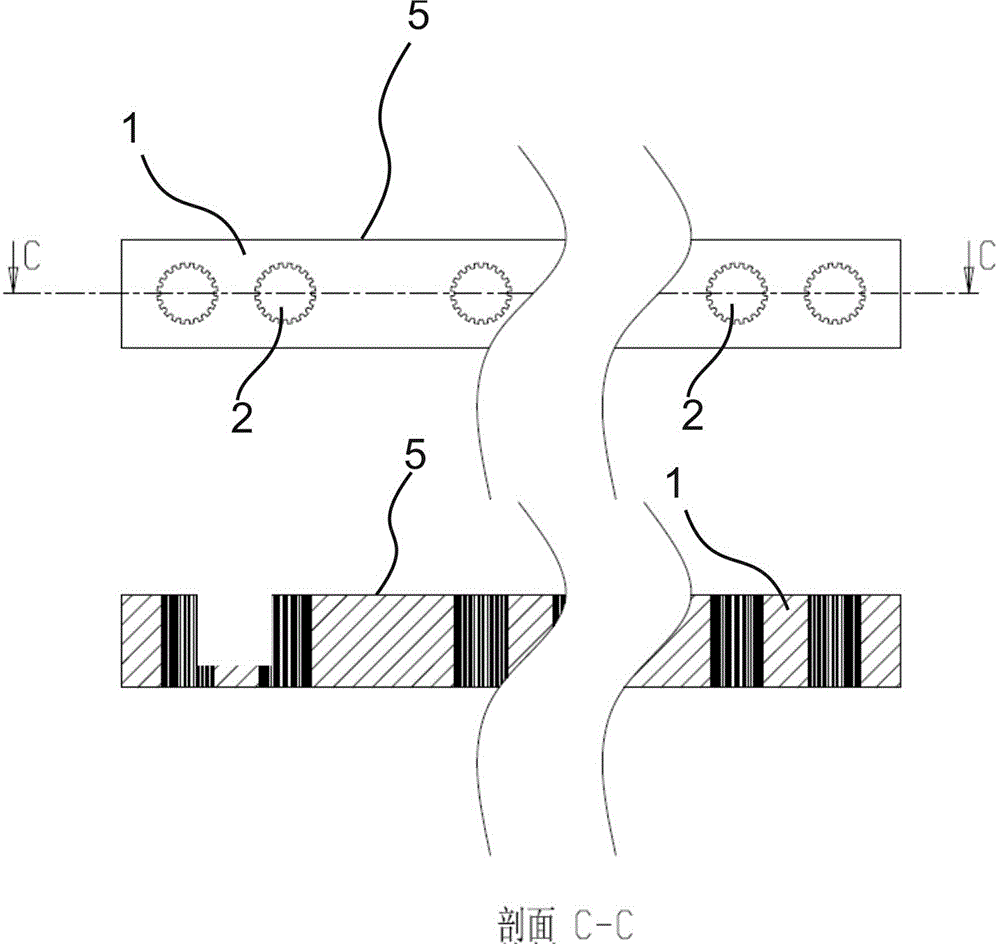

The invention provides a multi-array planar heat tube which is made of planar extruded sectional materials. The outer surface of the multi-array planar heat tube is a plane and is made of metal such as aluminum and copper and non-metal materials. The multi-array planar heat tube comprises a plurality of micro-holes which are arranged in an array mode. Each micro-hole is of an independent structure and is tubular. A plurality of fins are arranged on the surfaces in the micro-holes, the fins are parallel to one another, the intervals between the adjacent fins are equal, grooves are formed between the adjacent fins, and therefore the grooves which are distributed periodically are formed. According to the multi-array planar heat tube, the temperature of the whole plane can be kept uniform easily, the axial heat transmission speed of the planar heat tube is increased, the heat transmission performance between an LED light source and a radiator is improved, heat resistance between the LED light source and the radiator is reduced, therefore, the heat management performance of the LED light source is improved and the cost of the LED light source is reduced. When the multi-array planar heat tube is used in a solar photo-electric water heating system, the heat exchanging area can be increased, the heat exchanging efficiency is improved and the photovoltaic power generating efficiency is indirectly improved.

Description

technical field [0001] The invention relates to a heat transfer tube with a planar feature and composed of multiple micro heat pipe structures, which can be used in the heat dissipation part and heat conduction of LED light source heat dissipation, solar hot water, solar photovoltaic and heat collection composite systems and other in the component. The present invention more particularly designs a planar heat pipe with a planar installation function, in which a plurality of micro-heat pipe structures with grooves and heat dissipation fins are arranged in an array. This structure can significantly improve the temperature uniformity of the outer plane of the planar heat pipe, thereby improving The contact area for product heat exchange improves the overall heat transfer performance. Background technique [0002] Planar heat pipes with planar features can first be used as heat exchange devices with planar heating characteristics, including power LED light sources, solar hot wa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F28D15/02

Inventor 修强林闽李卫华张艳红

Owner 新疆品源太阳能科技开发有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com