X-radiographic ellipse projection laser positioning method for small-diameter pipe

A technology of laser positioning and small-diameter tubes, which is applied in the use of radiation for material analysis, etc., can solve the problems of increasing working time, reducing work efficiency, and inappropriate on-site detection of small-diameter tubes, so as to improve work efficiency and ensure the quality of inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

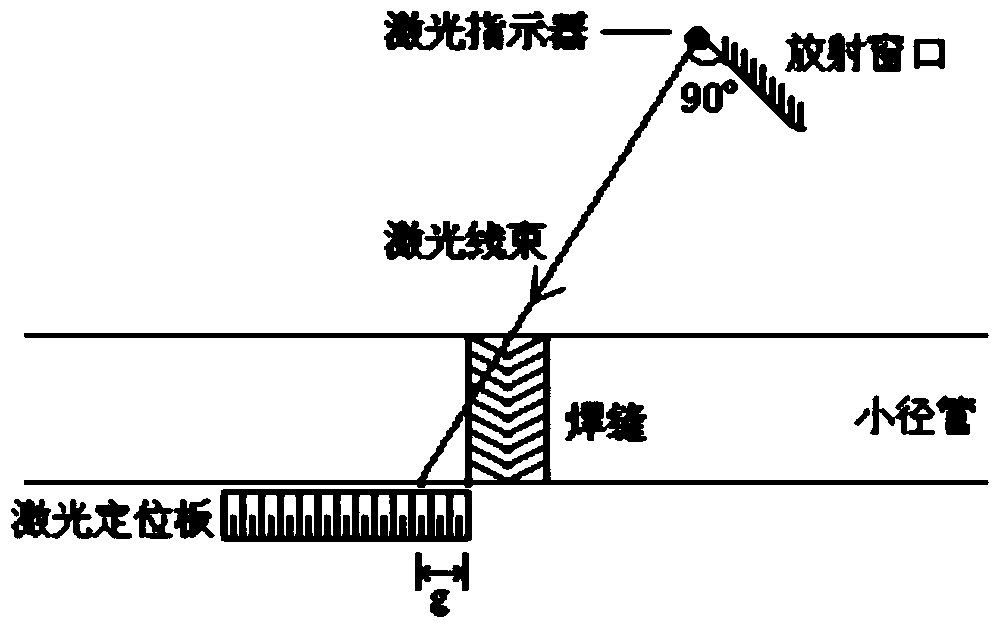

[0015] A small-diameter tube X-ray photographic ellipse projection laser positioning method, such as figure 1 As shown, for the detection of small-diameter tubes, the equipment used in the inventive method includes a ray machine, a laser indicator of the ray machine and a laser display panel. The steps of the inventive method are as follows:

[0016] (1) Equipment placement; if figure 1 As shown, the X-ray machine is placed on the side of the small-diameter tube, so that the radiation window of the X-ray machine is aligned with the weld seam, and the beam emitted by the laser pointer of the X-ray machine traverses the weld seam and is positioned on the laser positioning plate on the film side of the weld seam; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com