Large wafer cleaning machine

A cleaning machine and large-scale technology, applied in the field of cleaning machines, can solve problems such as difficult separation, dirty cleaning of wafers, and affecting physical properties of wafers, so as to reduce impact, improve production yield, and ensure quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

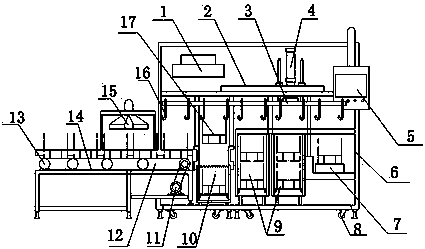

[0024] Such as figure 1 Shown, a kind of large-scale cleaning machine, it comprises frame 6, high-pressure air-drying device 15, described frame 6 middle and lower part is erected with feeding workbench 7, a plurality of ultrasonic cleaning tanks 9 successively from right to left, this implementation There are two ultrasonic cleaning tanks 9 in the example, an ultrasonic vibrating plate, a slow pulling dewatering tank 10, and a conveying device 12. The ultrasonic vibrating plate is arranged below the ultrasonic cleaning tank 9 body, and the top of the frame 6 is provided with geared motor, guide rail 2 and single-arm manipulator 3, the single-arm manipulator 3 straddles the guide rail 2 and is driven by the geared motor to move the single-arm manipulator 3 horizontally on the guide rail 2, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com