Automatic edge finding system for machine tool workpiece

An automatic edge finding and workpiece technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as operator operation and calculation errors, time and accuracy constraints, manual edge finding, etc., to achieve edge finding time. Short, meet the processing requirements, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

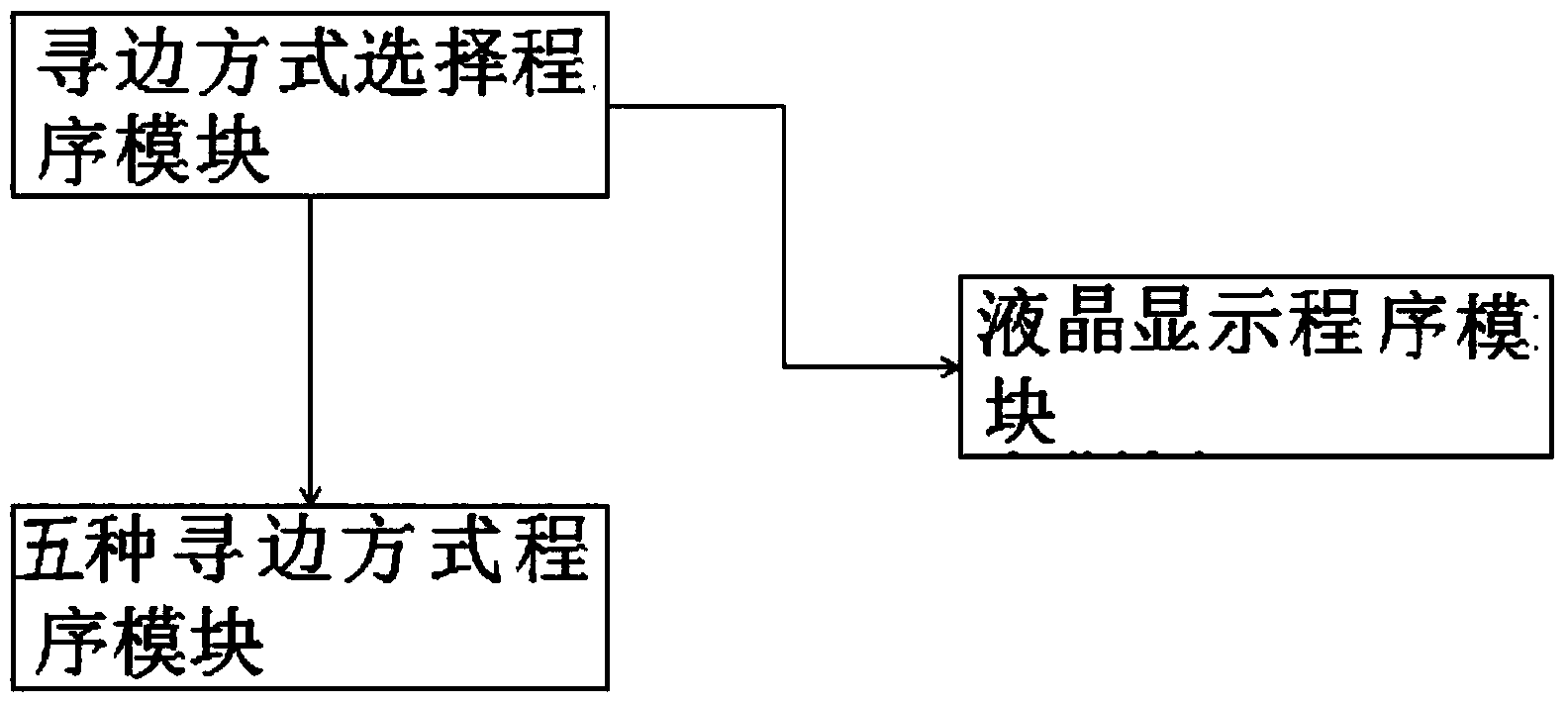

[0026] The machine tool workpiece automatic edge finding system described in this embodiment includes a hardware part and a software part, wherein,

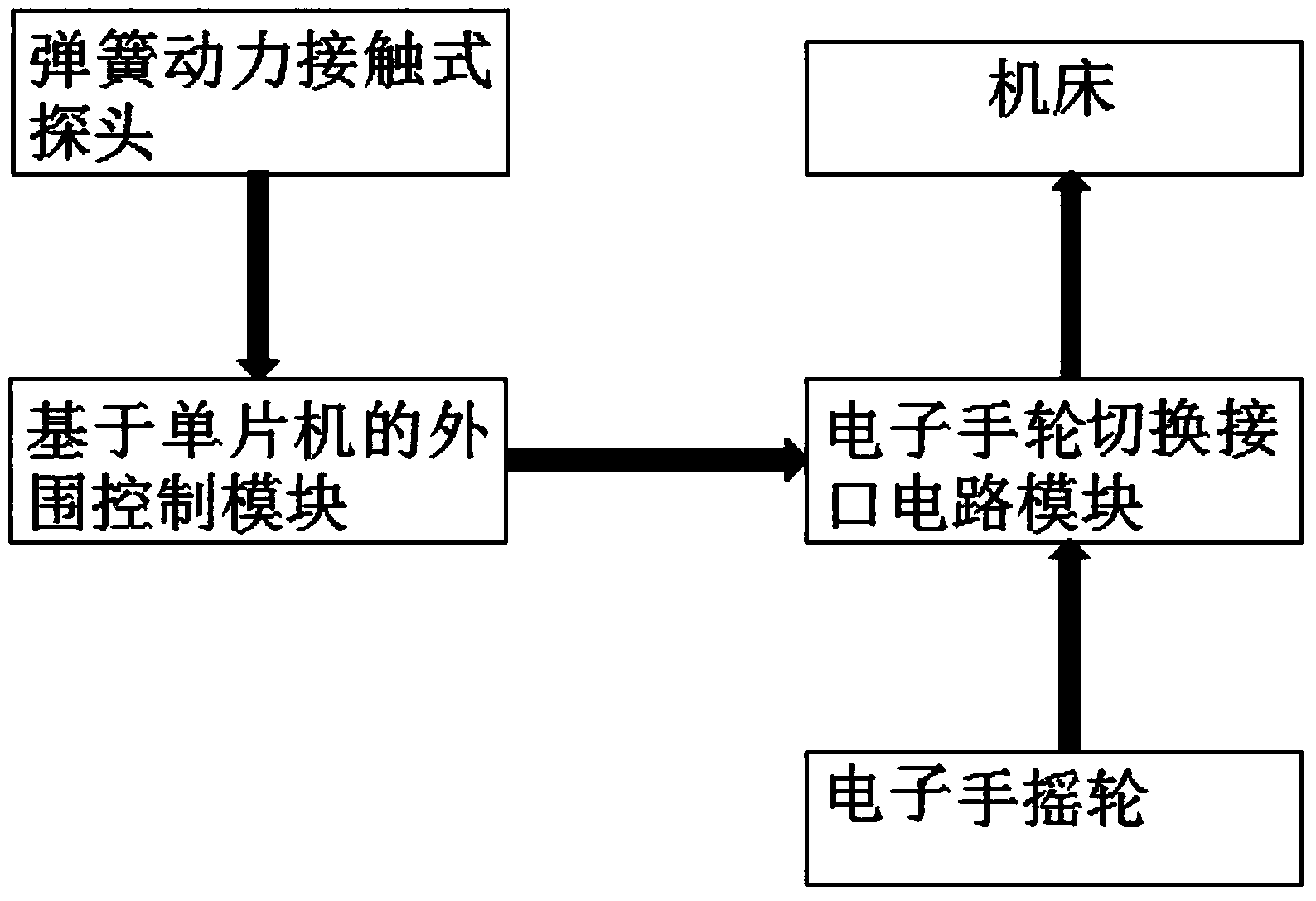

[0027] Such as figure 1 As shown, the hardware part includes:

[0028] The spring-powered contact probe is installed on the spindle of the machine tool, and has a probe that can make the optical signal on and off. The laser transceiver module on it can generate high and low level signals according to the up and down movement of the probe;

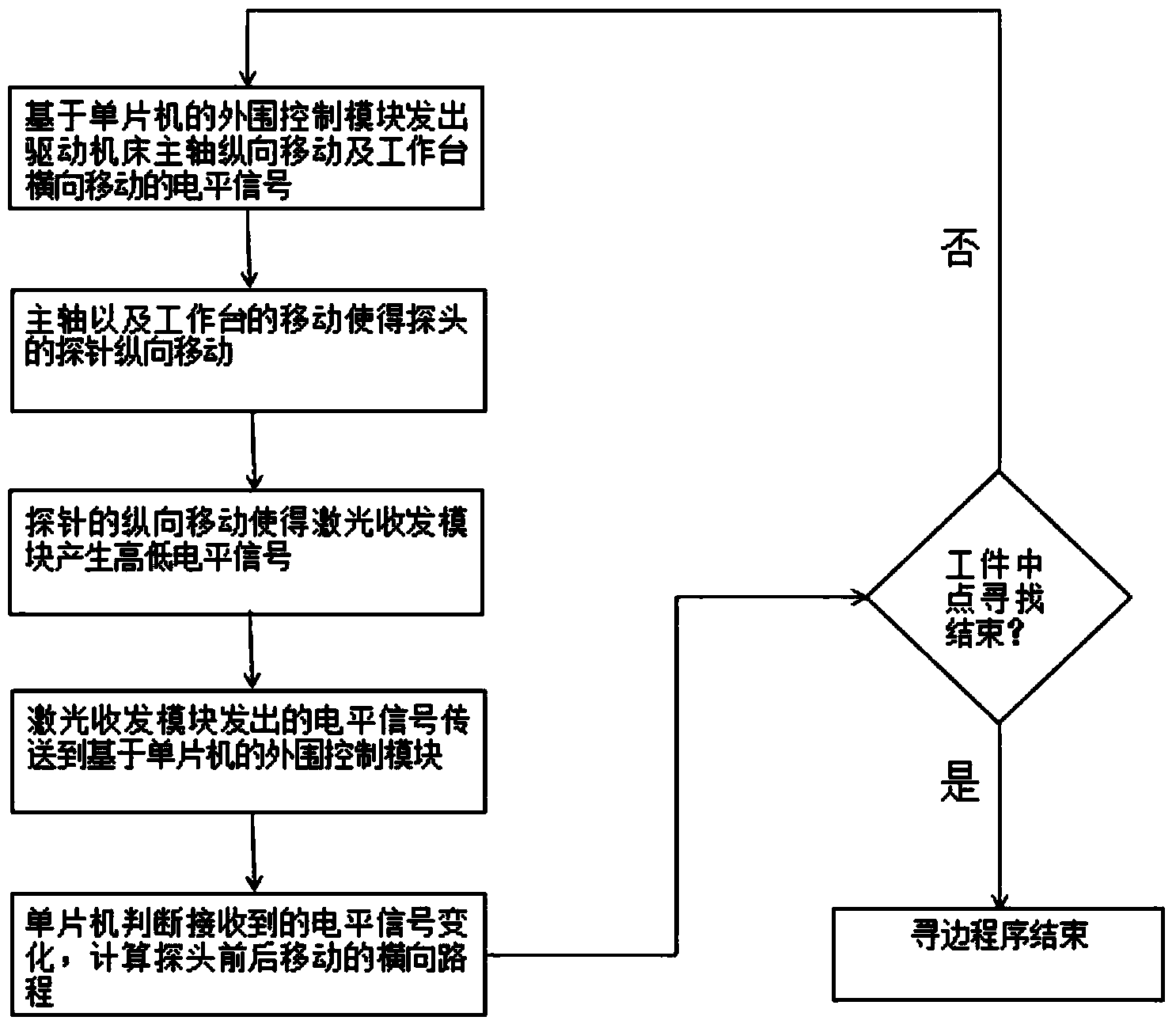

[0029] The peripheral control module based on the single-chip microcomputer can generate a level signal recognized by the machining center controller to control the longitudinal movement of the machine tool spindle and the lateral movement of the machine tool platform. The lateral movement of the machine tool platform causes relative movement between the workpiece and the probe pressed on it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com