Printing method imitating raising three-dimensional printing lines and printed products thereof

A printing method and three-dimensional technology, which is applied to the printing method of embossing three-dimensional printing and its printed products, can solve the problems of low usage, failure to meet the high expectations of the industry and consumers, and affect the overall material and shape. To achieve the effect of saving printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

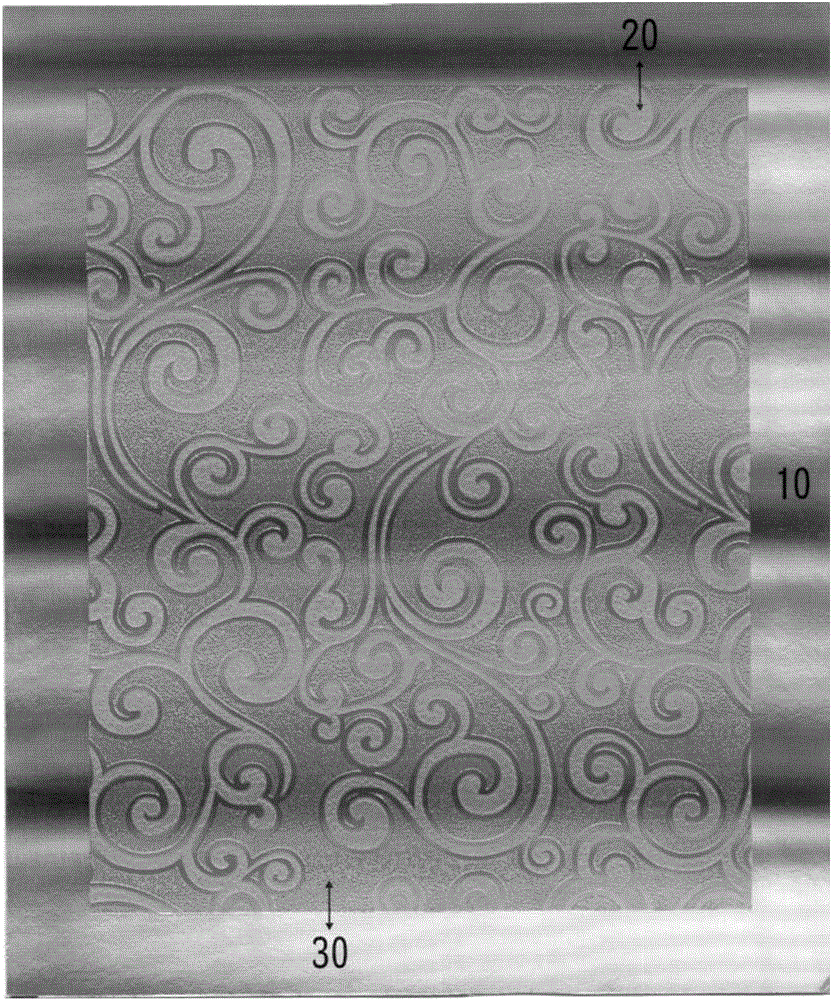

[0023] In order to further understand the technical means and characteristics of the present invention, the drawings (and actual printing samples) are described in detail below:

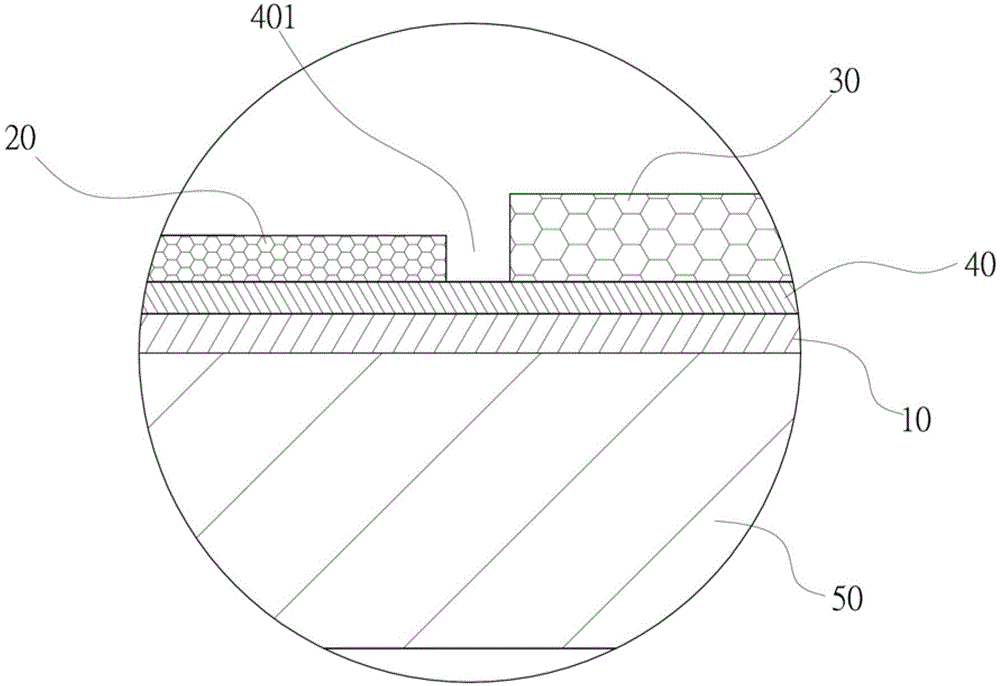

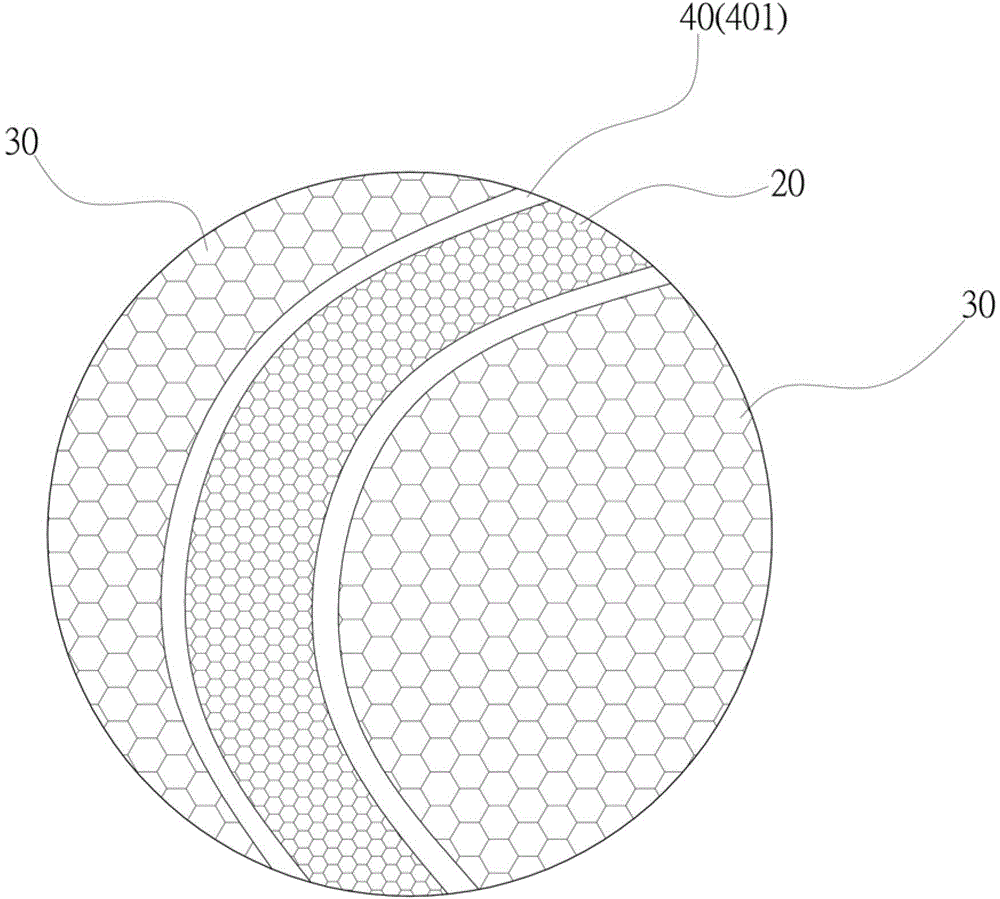

[0024] Such as figure 1 , figure 2 As shown, it is a partially enlarged schematic diagram of a partial section of the present invention and a partially enlarged schematic diagram of a printing layout, which is mainly to paste a layer of optical composite glare base film 10 on a water-absorbent printed material 50, and then apply the glare On the base film 10, print out the basic colored printing layer 40 with general ink, and then, on the basic colored printing layer 40, print a local three-dimensional ice layer 20 with a certain height with ice ink, and then print with a certain height with frosted ink. The height of the partial three-dimensional frosted layer 30, and make the basic color printing layer 40 as the interval line 401 between the ice flower layer 20 and the frosted layer 30.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com