A load-isolated gasoline-electric hybrid power system

An oil-electric hybrid power and load isolation technology, which is applied in the direction of hybrid vehicles, power devices, air pressure power devices, etc., can solve problems such as separation, work deterioration, and environmental pollution, so as to reduce capacity requirements and improve battery capacity. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

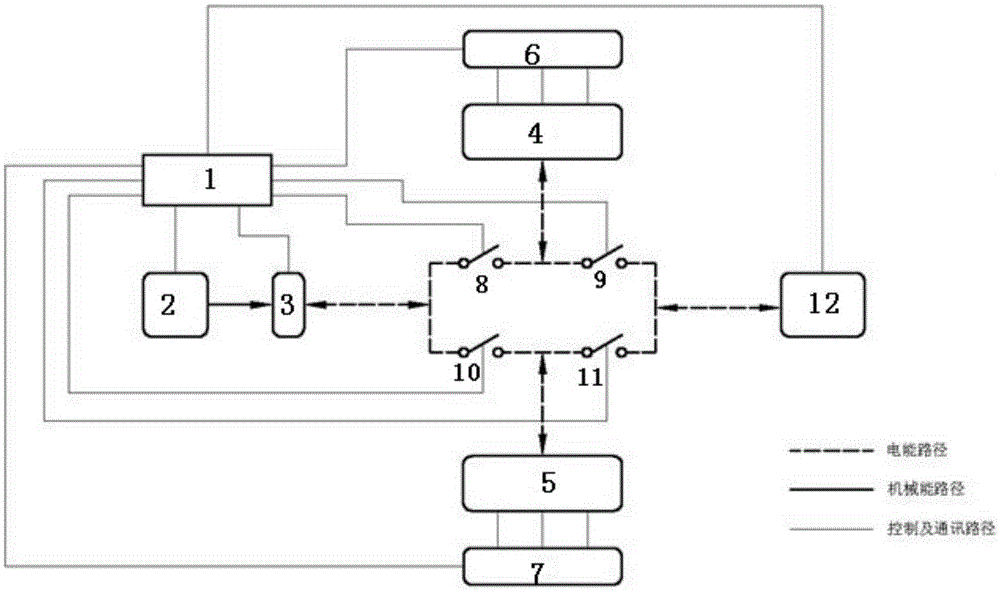

[0012] The main structure of this embodiment includes a central controller 1, a fuel engine 2, a generator 3, a first energy storage battery pack 4, a second energy storage battery pack 5, a first battery pack management system 6, and a second battery pack management system 7. The first adjustment switch 8, the second adjustment switch 9, the third adjustment switch 10, the fourth adjustment switch 11 and the electric energy output control device 12; 3 connection; the first adjustment switch 8 and the second adjustment switch 9 are connected in parallel with the third adjustment switch 10 and the fourth adjustment switch 11 connected in series to form an adjustment switch group; the adjustment switch group is respectively connected with the first energy storage battery group 4, the second The second energy storage battery pack 5 is electrically connected to the electric energy output control device 12; the first battery pack management system 6 and the second battery pack manag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com