Integrated tension device and crawler-type walking machine with same

A tensioning device and an integrated technology, applied in the field of machinery, can solve the problems of unguaranteed installation progress and construction safety, inability to realize modular assembly, and difficult control of assembly quality, so as to reduce the number of parts and simplify installation and disassembly Steps, Effects of Simplified Spring Boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

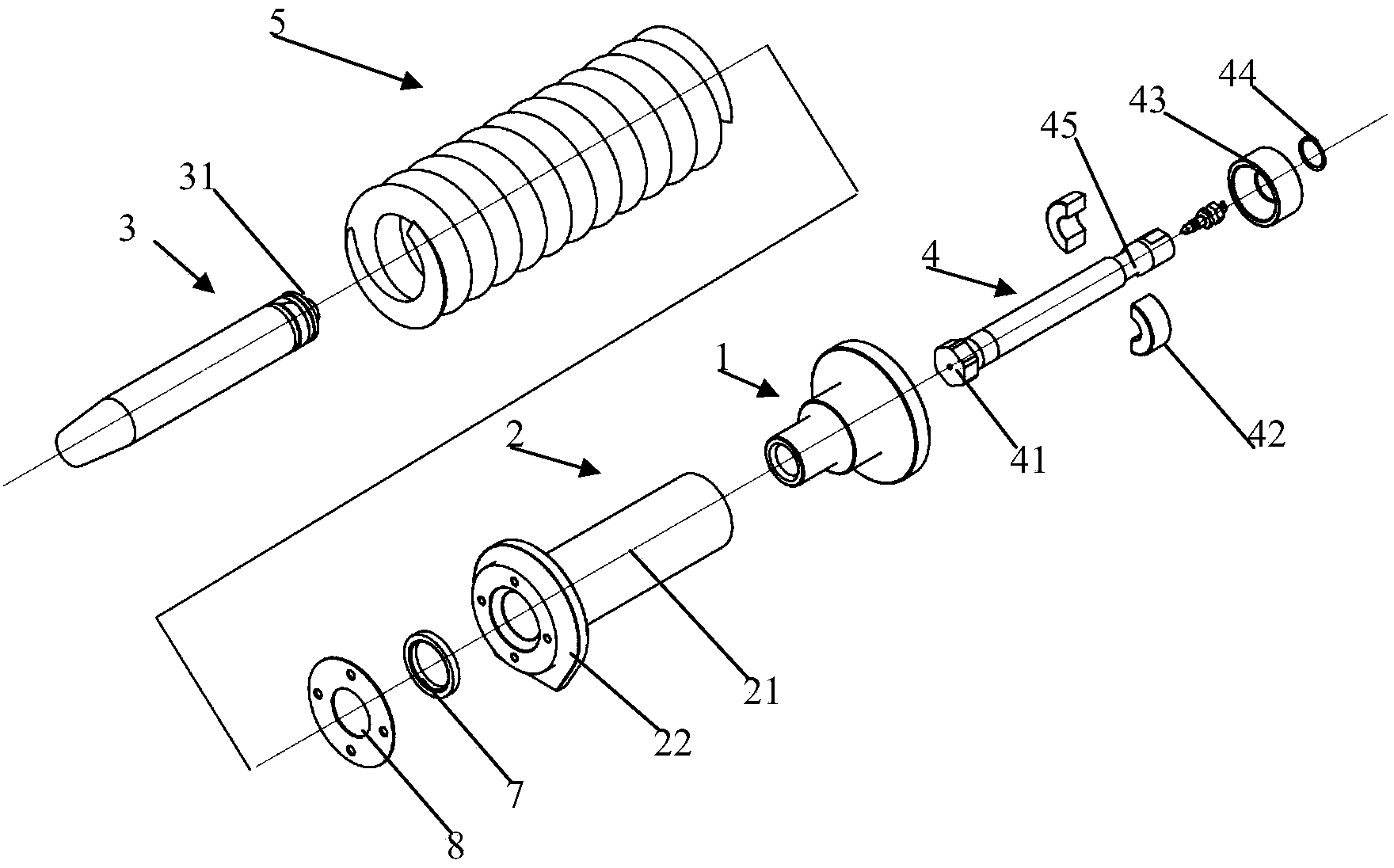

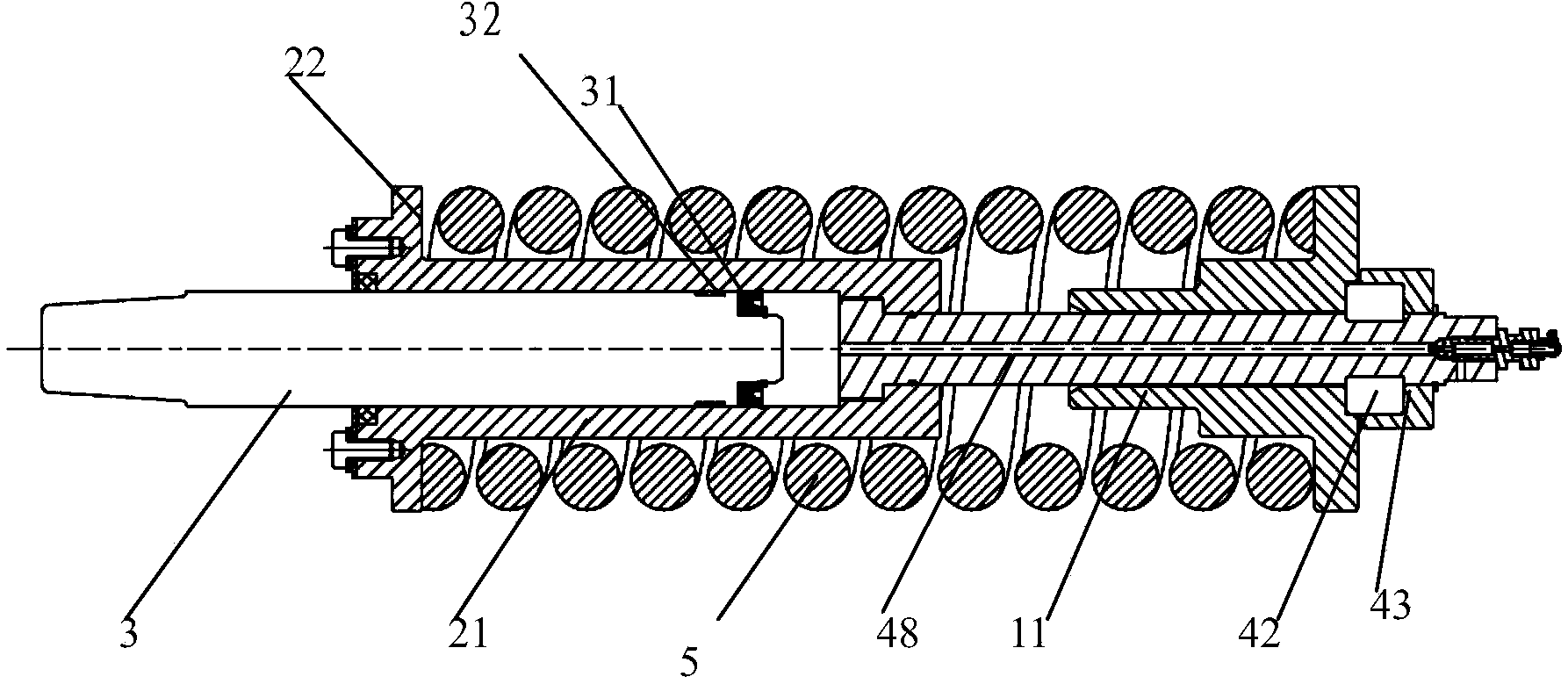

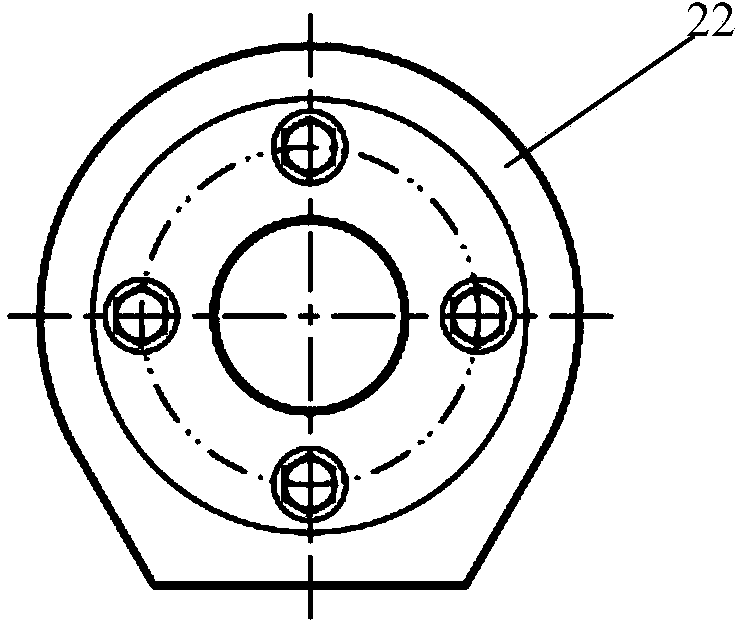

[0023] Such as figure 1 with 2 As shown, the tensioning mechanism of the present invention includes a rear guide seat 1, a front guide seat 2, a shaft 3, a pull rod 4 and a spring 5, wherein the rear guide seat section is a convex structure, which includes a cylinder and an integrally formed A flange-shaped protruding ring at the rear end of the cylinder, and the center of the rear guide seat is provided with an axial through hole; the front guide seat includes a cylinder 21 with an open front end and a flange-shaped outer edge 22 integrally forming the front end of the cylinder , the front end of the shaft is a truncated cone structure so as to be inserted into the assembly hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com