Elevator rope sheave

A sheave and elevator technology, applied in the field of elevator sheaves, can solve problems such as elevator rope escape, elevator rope limit, maintenance trouble, etc., and achieve the effects of improving running performance, good noise reduction performance, and improving coordination stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

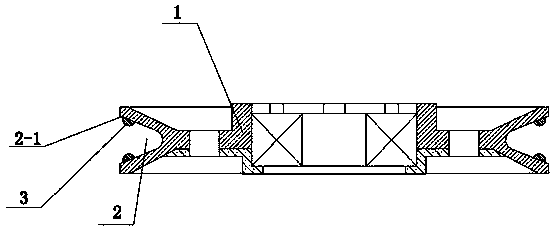

Embodiment 1

[0015] Such as figure 1 As shown, the elevator sheave provided in this embodiment includes a sheave main body 1, an arc-shaped rope ring groove 2 is provided on the outer wall of the sheave main body 1, and the notch of the above-mentioned arc-surface rope ring groove 2 2-1 is symmetrically provided with a rope limiting protruding ring 3 .

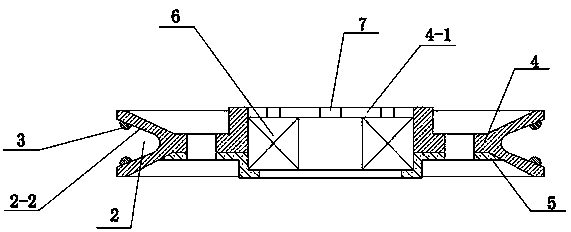

Embodiment 2

[0017] Such as figure 2 As shown, the general structure of the elevator sheave provided by this embodiment is consistent with that of Embodiment 1, but the main body 1 of the sheave described in this embodiment specifically includes a base 4, a cover plate 5 and a bearing 6, and the base 4 There is a bearing hole 4-1 on the top, the bearing 6 is placed in the bearing hole 4-1, the cover plate 5 is riveted on the base 4, and covers the edge of one side of the bearing hole 4-1, and the other side of the bearing hole 4-1 A riveting point 7 for a fixed bearing 6 is provided along the periphery of one side opening, and an arc-shaped rope ring groove 2 is also provided on the outer wall of the base 4 . In the above preferred solution, the bearing 6 in the sheave main body 1 is easy to install and has good structural stability.

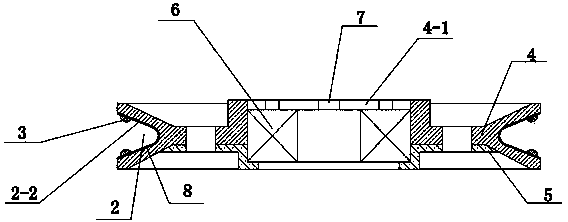

Embodiment 3

[0019] The general structure of the elevator sheave provided in this embodiment is the same as that of Embodiment 2, but in order to prevent the elevator ropes from producing noise after contacting and rubbing the elevator sheave, it will have a negative impact on the use of the entire elevator landing door system, such as image 3 As shown, the groove surface 2-2 of the curved rope loop groove 2 in this embodiment is provided with a nylon covering layer 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com