Adhesive for plywood and preparation method thereof

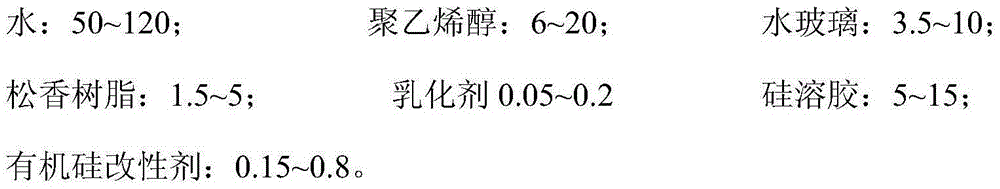

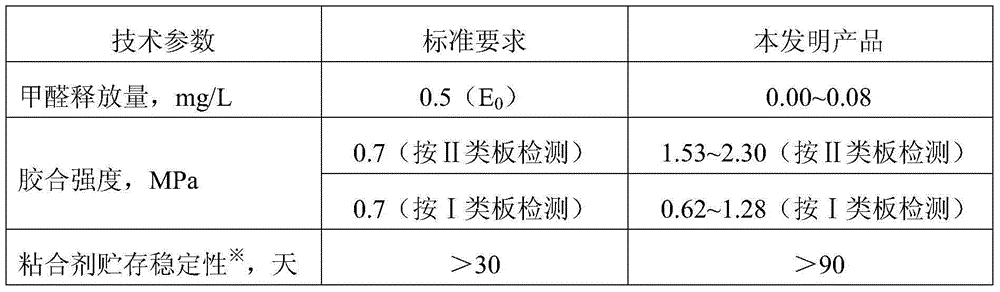

A technology for plywood and adhesives, applied in the directions of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of poor adhesion performance, high cost of use, less artificial boards, etc., and achieve adhesion strength and water resistance. High, simple manufacturing process and equipment, and the effect of avoiding the harm of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 500g of water into a three-neck flask equipped with an electric stirrer and a thermometer, heat it in a water bath to 50°C, add 60g of polyvinyl alcohol of model 2488 under stirring, and continue to heat up to 95°C to completely dissolve the polyvinyl alcohol. Then add 35g of sodium silicate water glass with a silicon dioxide content of 28% and stir evenly, then add the mixture of 7.5g of crushed gum rosin and 7.5g of polymerized rosin in 3 times, each time at an interval of 10 minutes, and then add K12 for emulsification Add 0.5 g of the solution, keep the temperature at 90°C for 30 minutes, and cool to room temperature. Add 50g of silica sol with a silica content of 30% and stir evenly, slowly add a sulfuric acid solution made of sulfuric acid and water in a weight ratio of 1:1 to adjust the pH value to 6.5, and then dropwise add γ-methacryloyloxy 1 g of propyltrimethoxysilane and 0.5 g of γ-glycidoxypropyltrimethoxysilane were stirred and dispersed evenly, and th...

Embodiment 2

[0031] Add 1000kg of water into the reaction kettle, raise the temperature to 60°C, add 160kg of polyvinyl alcohol (type 1788) under stirring, and continue to heat up to 90°C to completely dissolve the polyvinyl alcohol. Then adding silicon dioxide content is 24% water glass 75kg and stirs evenly, then adds the gum rosin 40kg that pulverizes in 3 times equally, every interval 10 minutes, adds K12 emulsifying agent 1kg and NP-10 emulsifying agent 0.25kg again, Keep the temperature at 90°C for 25 minutes and cool to room temperature. Add 100kg of silica sol with a silica content of 20% and stir evenly, slowly add acetic acid to adjust the pH value to 7.0, then dropwise add 8kg of γ-methacryloxypropyltrimethoxysilane and stir to disperse evenly, continue stirring for 3.5 Hours, filtered and discharged for later use. Before use, according to the viscosity requirement, add peanut shell powder whose weight is 3% of the weight of the feed liquid and stir evenly to obtain an adhesive...

Embodiment 3

[0033] Add 1200kg of water into the reactor, raise the temperature to 60°C, add 100kg of polyvinyl alcohol of type 1799 and 60kg of polyvinyl alcohol of type 2499 under stirring, and continue to heat up to 92°C to completely dissolve the polyvinyl alcohol. Then add 100kg of water glass with a silicon dioxide content of 28% and stir evenly, then add 40kg of pulverized hydrogenated rosin in 3 times, each time at an interval of 15 minutes, then add 1.5kg of LAS emulsifier, and keep the temperature at 90°C for 30 minutes. , cooled to room temperature. Add 120kg of silica sol with a silicon dioxide content of 35% and stir evenly, slowly add sulfuric acid and water in a weight ratio of 1:1 to adjust the pH value to 7.0, and then dropwise add gamma-glycidoxypropyl 6.5 kg of trimethoxysilane was stirred and dispersed evenly, and the stirring was continued for 5 hours, and the material was filtered and discharged for later use. Before use, add mica powder (130 meshes) whose weight is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com