Flexible basic structure for high speed railway ballastless track and laying method of track

A ballastless track, high-speed railway technology, applied in the direction of track, road, ballast layer, etc., can solve the problems of being unable to be used as a flexible foundation structure material of ballastless track, asphalt concrete deformation, loss of waterproof function, etc., to achieve long service life, Easy maintenance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and example the present invention will be further described.

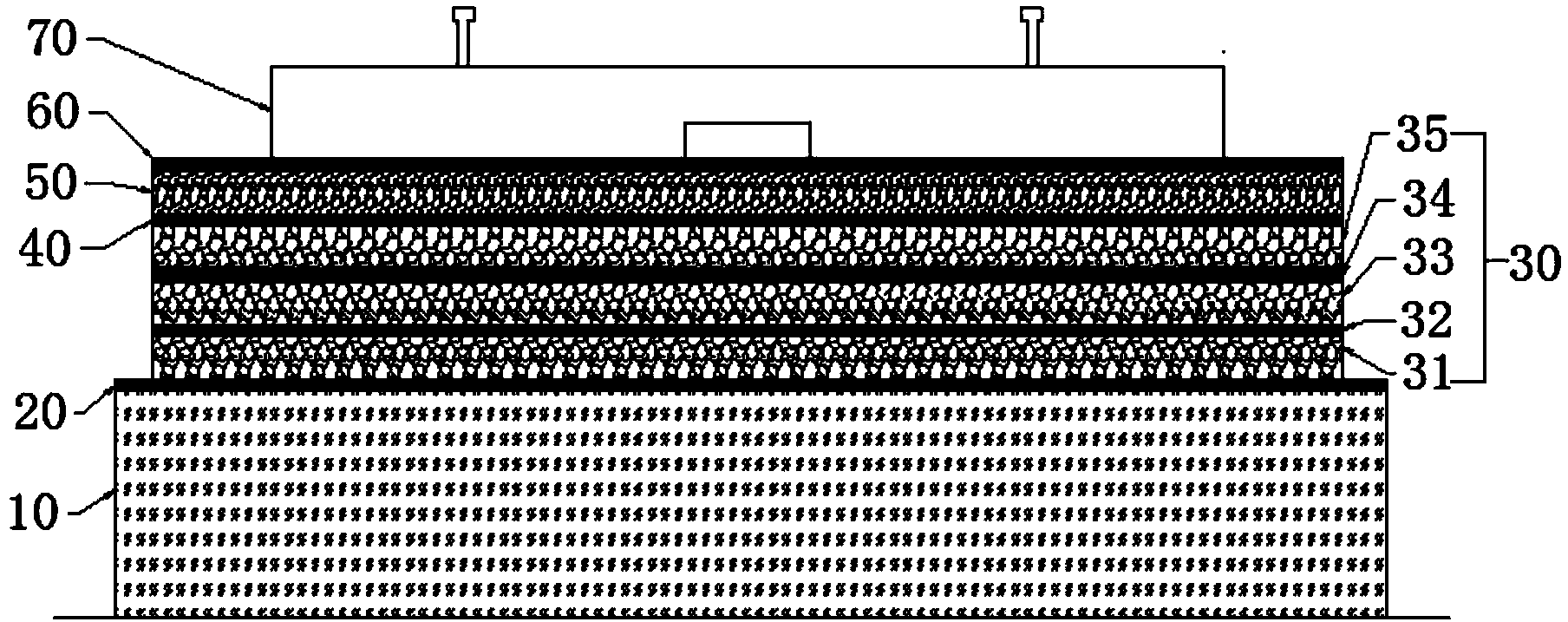

[0039] Such as figure 1 As shown, the flexible foundation structure for the high-speed railway ballastless track of the present embodiment is provided with an asphalt base 30, an asphalt surface layer 50 and a superstructure 70 on the antifreeze base 10 from bottom to top, and the antifreeze base 10 and the asphalt base 30 pass through The lower bonding layer 20 is bonded, the asphalt base layer 30 and the asphalt surface layer 50 are bonded through the middle bonding layer 40, and the asphalt surface layer 50 and the upper structure 70 are bonded through the upper bonding layer 60; the asphalt base layer 30 is Composite structure comprising at least three layers of modified epoxy asphalt concrete layers (the first layer of modified epoxy asphalt concrete layer 31, the second layer of modified epoxy asphalt concrete layer 33 and the third layer of modified epoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com