Rubber powder modified asphalt for pavement patching and preparation method thereof

A modified asphalt and pavement repair technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of limited comprehensive improvement effect and poor reactivity, and achieve good anti-aging performance, excellent oxidation resistance and heat resistance. , the effect of good road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

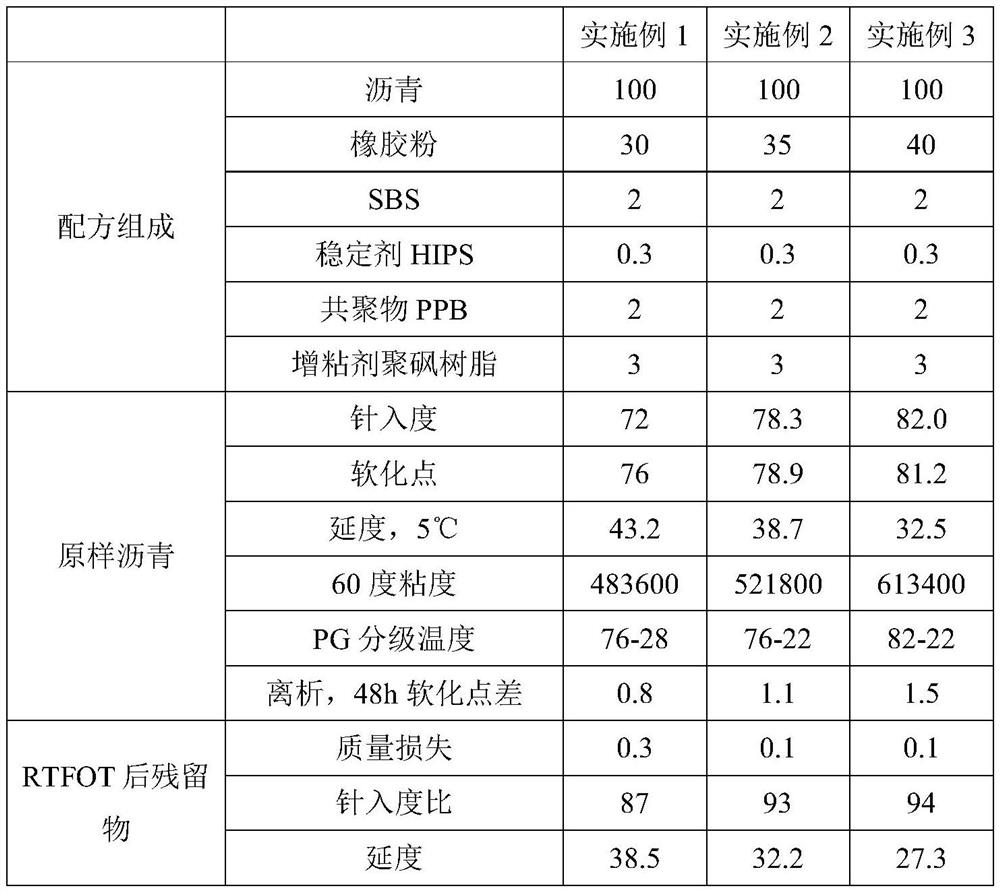

[0033] Examples 1 to 3 are a kind of rubber powder-modified asphalt for road surface repair with different rubber powder additions, including the formula composition shown in Table 1 below. The preparation method of described rubber powder modified asphalt is as follows:

[0034] Heat the asphalt to 250°C, then add rubber powder and stir for 6 hours to mix evenly, then cool down to 190°C, add thermoplastic elastomer and tackifying resin, stir and mix evenly, finally add HIPS and PPB and stir for 30 minutes to obtain the glue for road repair powder modified asphalt. The stirring rate in the whole process of the preparation method is controlled to be 1000-1500 r / min.

[0035] The performance test results of the original asphalt and residues after RTFOT are shown in Table 1 below.

[0036] Table 1

[0037]

[0038]From the test results in Table 1, it can be seen that with the gradual increase in the weight of rubber powder, the softening point of the modified asphalt increa...

Embodiment 4~6

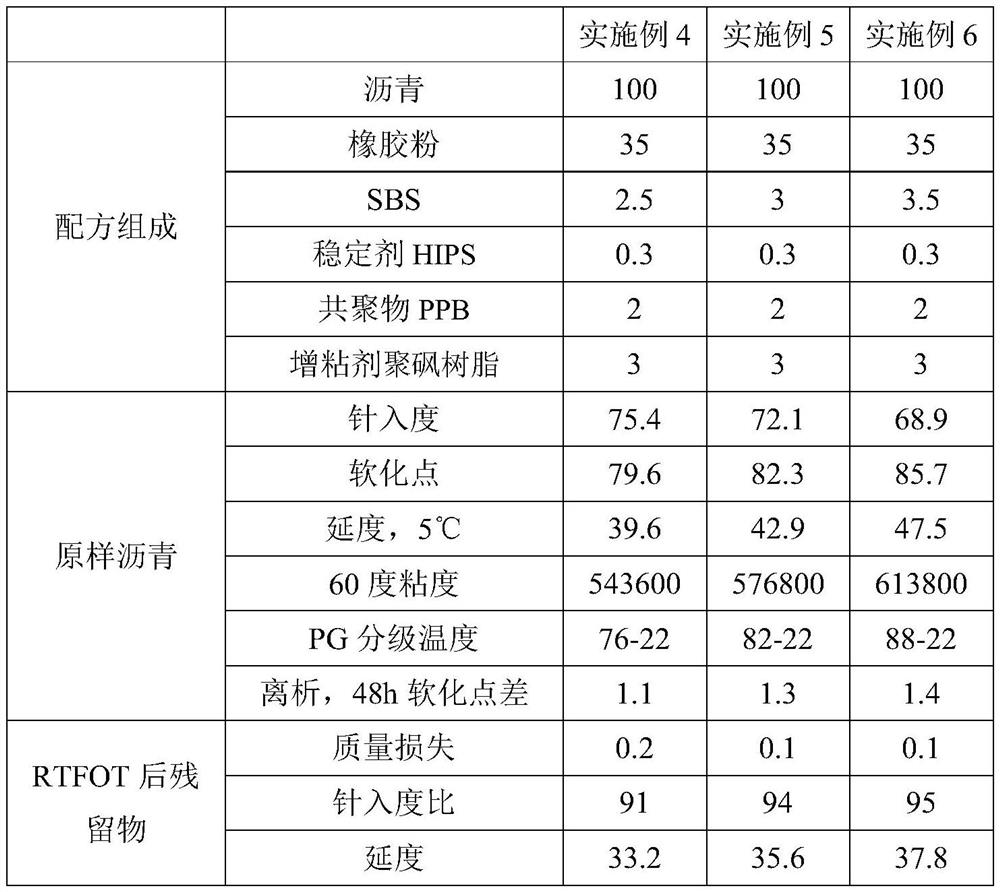

[0040] Examples 4 to 6 are a kind of rubber powder-modified asphalt for road surface repair under the condition of different SBS additions, including the formula composition shown in Table 2 below. The preparation method of described rubber powder modified asphalt is as follows:

[0041] Heat the asphalt to 250°C, then add rubber powder and stir for 6 hours to mix evenly, then cool down to 190°C, add thermoplastic elastomer and tackifying resin, stir and mix evenly, finally add HIPS and PPB and stir for 30 minutes to obtain the glue for road repair powder modified asphalt. The stirring rate in the whole process of the preparation method is controlled to be 1000-1500 r / min.

[0042] The performance test results of the original asphalt and residues after RTFOT are shown in Table 2 below.

[0043] Table 2

[0044]

[0045] From the test results in Table 2, it can be seen that as the weight fraction of SBS increases from 2.5 to 3.5, the softening point of asphalt increases f...

Embodiment 7~9

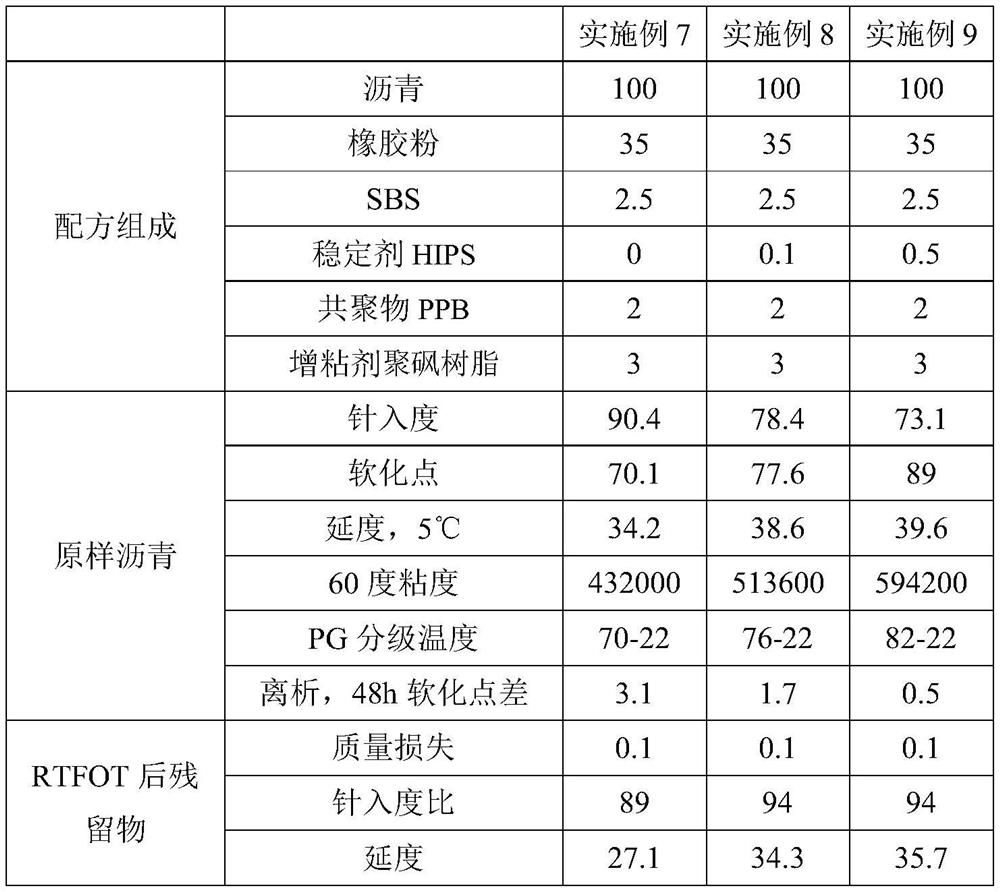

[0047] Examples 7-9 are rubber powder-modified asphalt for road surface repair under the condition of different addition amount of stabilizer HIPS, including the formula composition shown in Table 3 below. The preparation method of described rubber powder modified asphalt is as follows:

[0048] Heat the asphalt to 250°C, then add rubber powder and stir for 6 hours to mix evenly, then cool down to 190°C, add thermoplastic elastomer and tackifying resin, stir and mix evenly, finally add HIPS and PPB and stir for 30 minutes to obtain the glue for road repair powder modified asphalt. The stirring rate in the whole process of the preparation method is controlled to be 1000-1500 r / min.

[0049] The performance test results of the original asphalt and residues after RTFOT are shown in Table 3 below.

[0050] table 3

[0051]

[0052] From the test results in Table 3, it can be seen that the group without stabilizer HIPS had obvious segregation, and the difference between the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com