High-pressure sealed nitrogen spring

A nitrogen gas spring, high-pressure sealing technology, used in springs, springs/shock absorbers, gas-liquid shock absorbers, etc., can solve problems such as cost reduction, and achieve simple and reasonable structural design, stable temperature change control, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

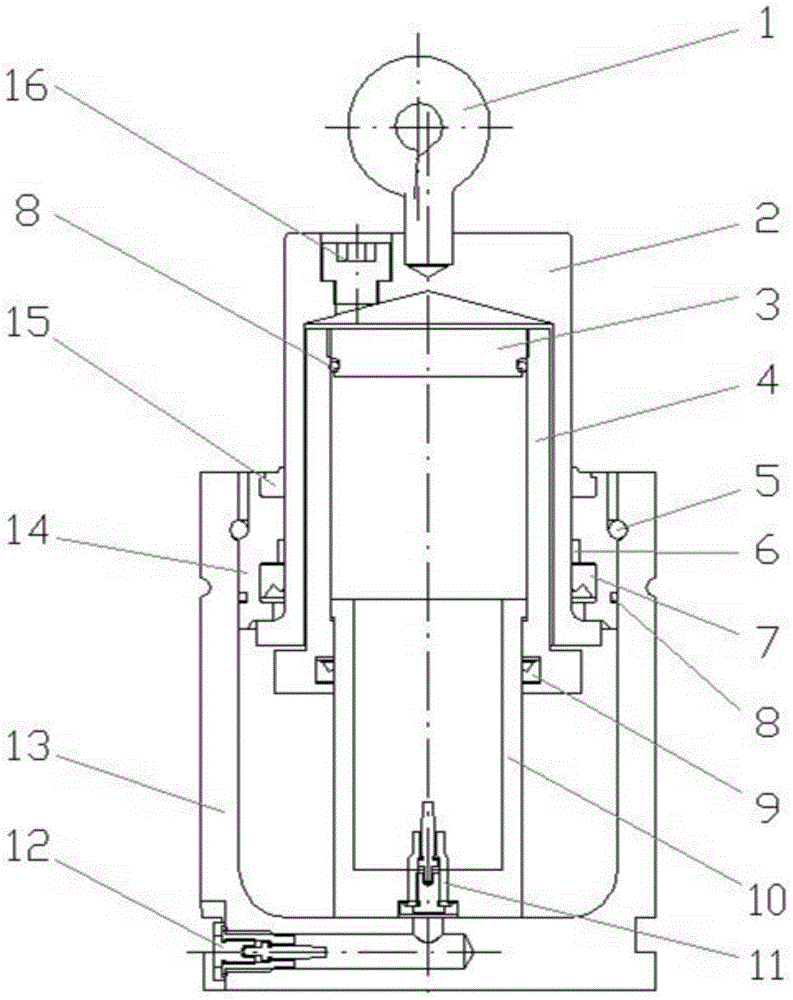

[0016] Such as figure 1 As shown, the high-pressure sealed nitrogen gas spring includes a cylinder part and a nitrogen cylinder part, and the nitrogen cylinder part filled with nitrogen is placed in the oil inside the cylinder part; the cylinder part includes a cylinder cavity plunger 2 and a cylinder block 13 The outer circumference of the oil cylinder cavity plunger 2 is covered with a guide sleeve 14, and the oil cylinder cavity plunger 2 and the guide sleeve 14 are sealed and flexibly connected by a dustproof seal 15 and a lip oil seal A7. A guide ring 6 is installed between the guide sleeves 14, and the guide sleeve 14 and the oil cylinder block 13 are sealed by an O-ring 8 and fixedly connected by a snap ring 5. A one-way oil injection valve assembly 12 is installed on the bottom of the oil cylinder block 13, The top of the oil cylinder cavity plunger 2 is provided with a sealing plug 16, and the top of the oil cylinder cavity plunger 2 is provided with a hoisting ring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com