Double-cone rotary vacuum drier with cutters

A vacuum dryer with a knife technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of affecting the drying effect of materials, forming agglomerates, etc., to increase permeability and speed up drying Speed, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

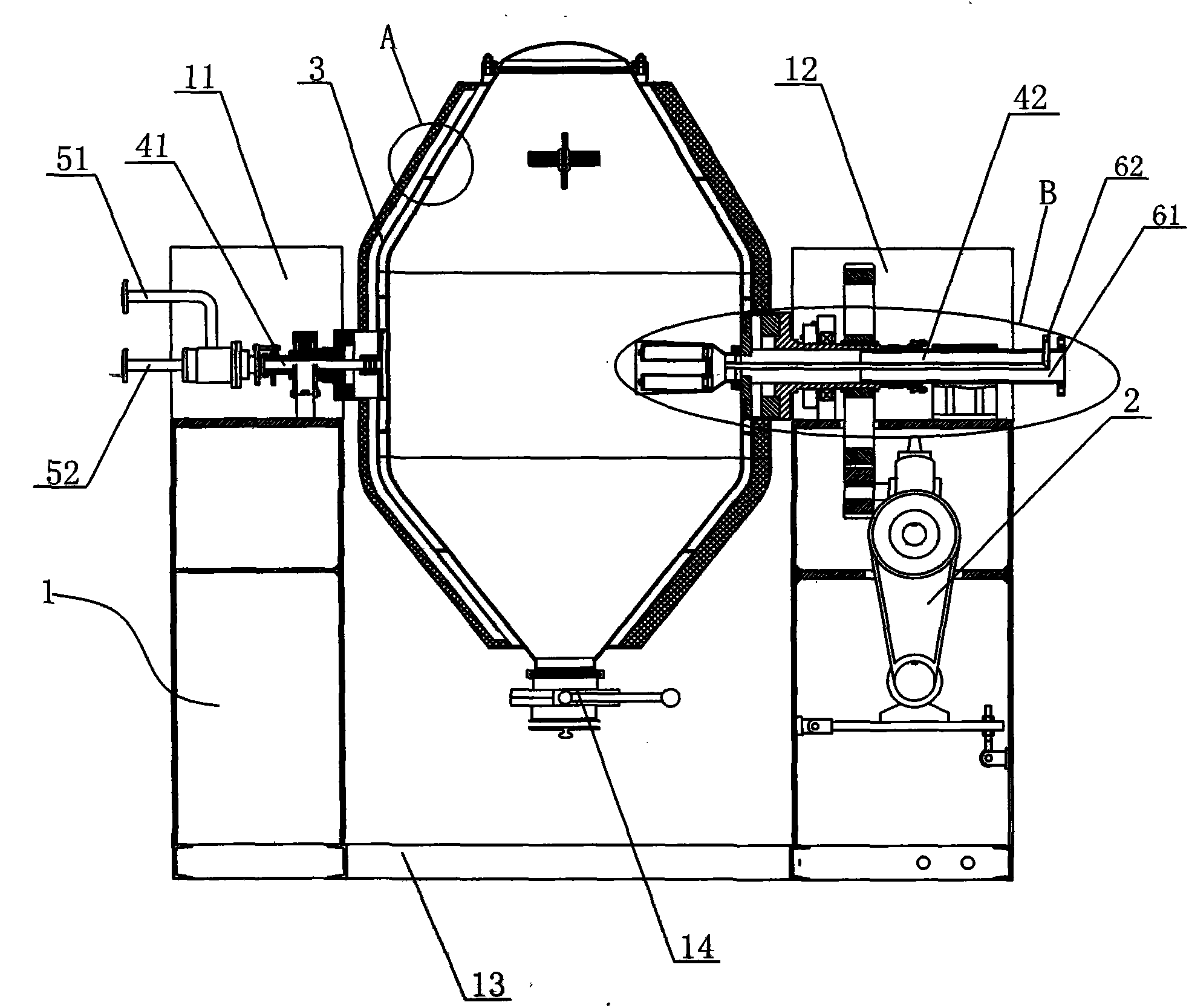

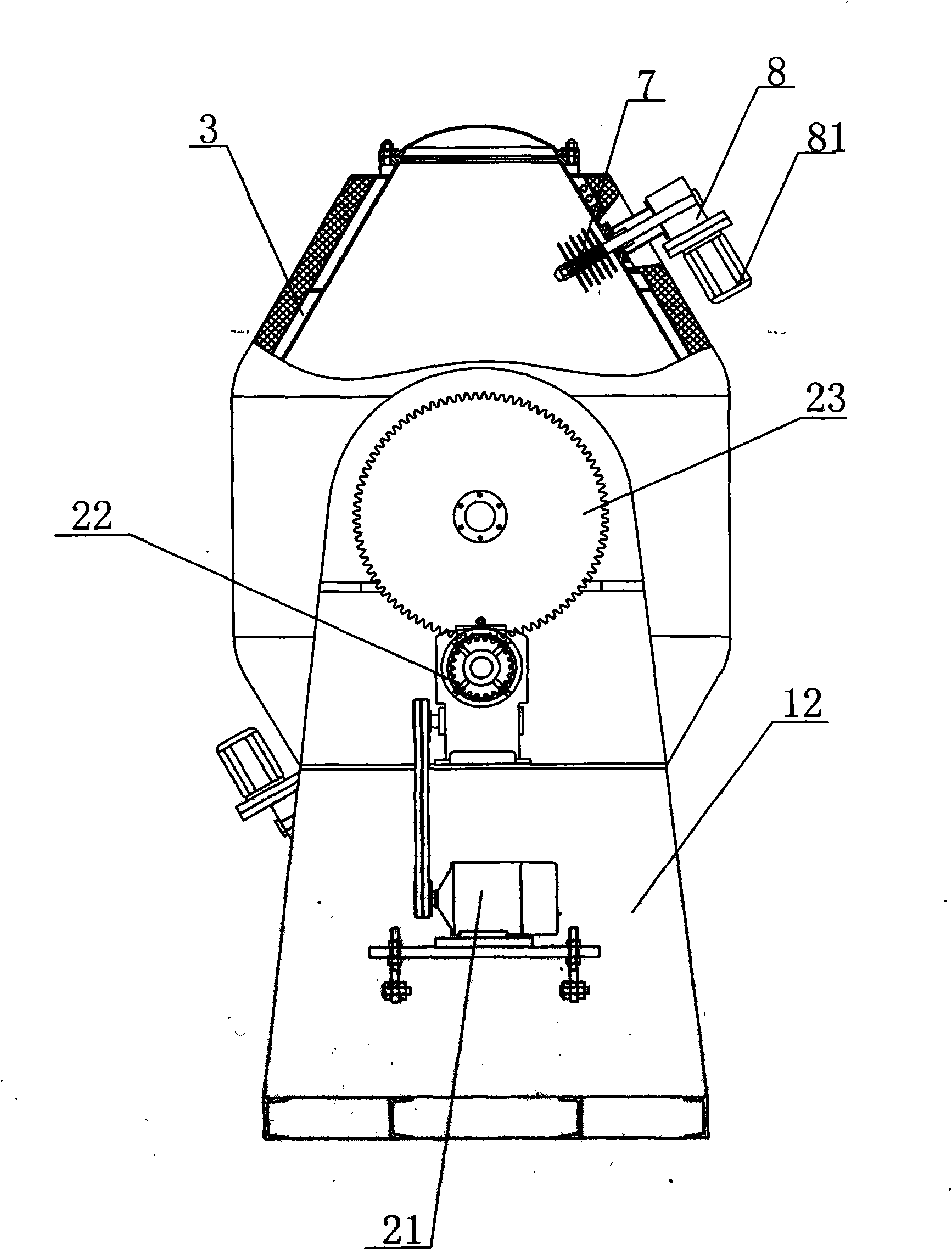

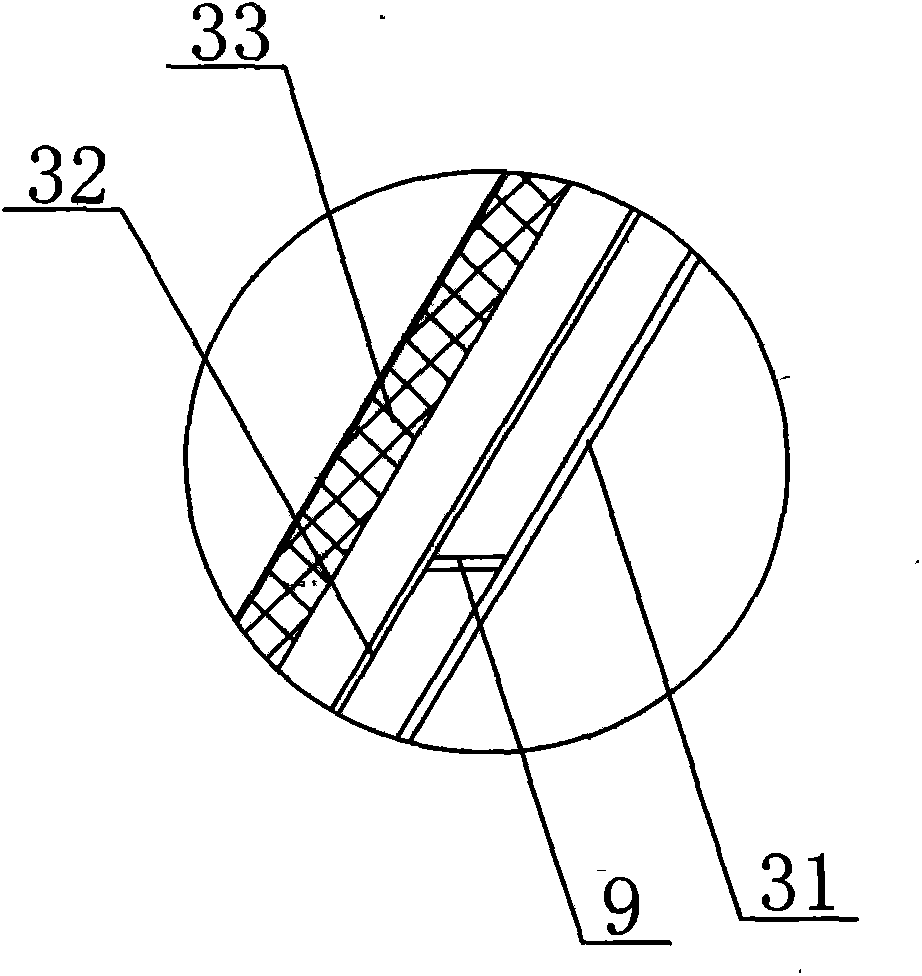

[0020] Such as figure 1 , 2 As shown, a double-cone rotary vacuum dryer with a knife includes a bracket 1, a transmission device 2, and a cylinder body 3. The bracket is provided with a left pillar 11, a right pillar 12, and a base 13, and the left and right pillars are connected by the base 13. Fixed, the cylinder 3 is arranged on the left pillar 11 and the right pillar 12 through the left spindle 41 and the right spindle 42 on both sides. Set on the corresponding main shaft bearing, the main shaft bearing is installed on the left pillar 11 and the right pillar 12, the transmission device 2 is arranged on one side of the cylinder body 3, and is connected with the left main shaft 41 or the right main shaft 42 of the cylinder body 3, in this embodiment Be connected with right main shaft 42 among the example, be made up of transmission device 2 by motor 21, speed redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com