LED junction temperature or average LED array junction temperature measuring method

A technology of LED array and measurement method, applied in radiation pyrometry, measurement device, optical radiation measurement, etc., can solve the monotonous relationship between peak wavelength and junction temperature, difficult LED pin voltage drop measurement, measurement environment and conditions For high-level problems, to achieve the effect of wide range of use, easy measurement and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below according to the drawings and specific embodiments of the specification.

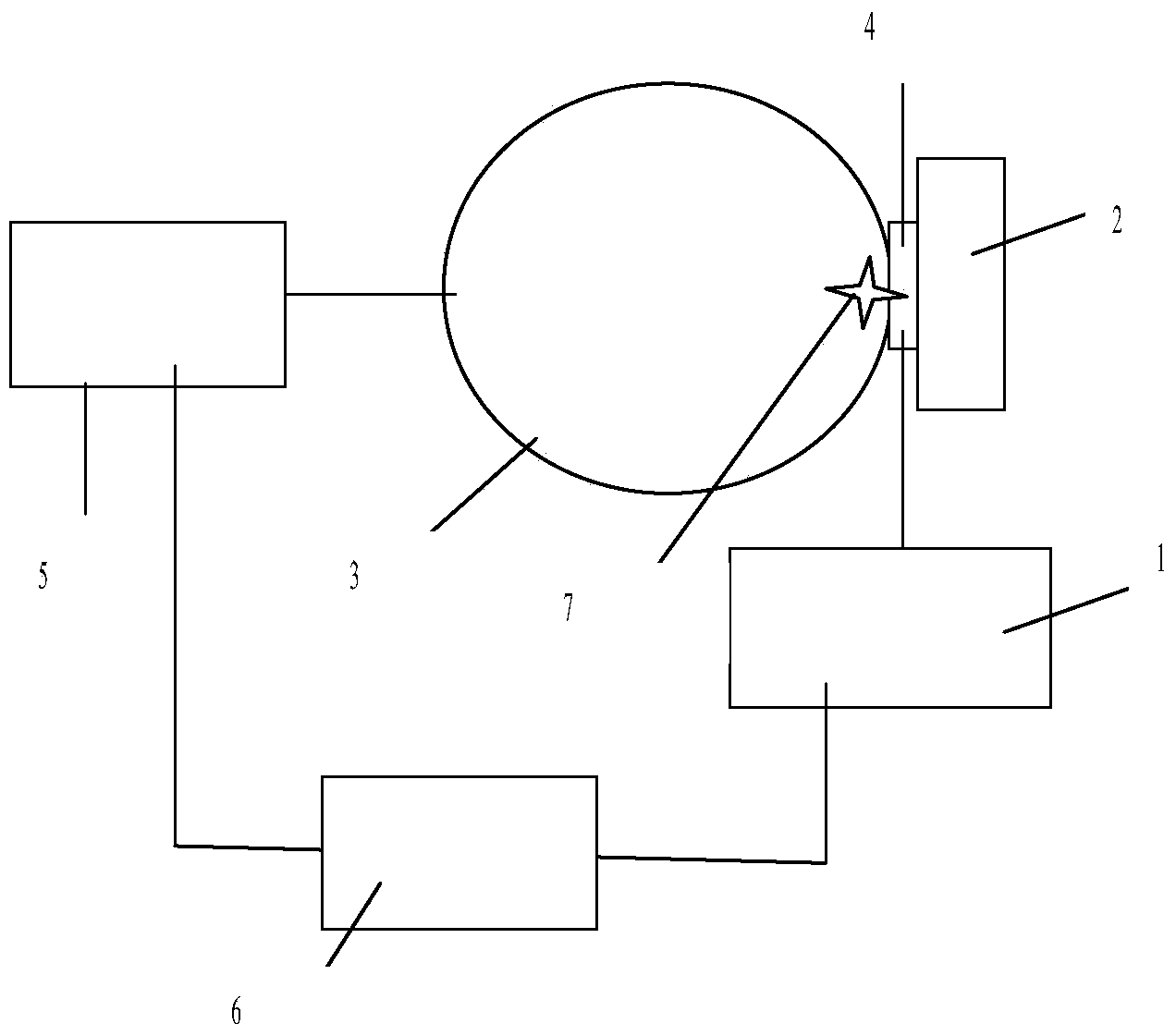

[0021] Such as figure 1 As shown, the measuring device of the LED junction temperature to be used in the present invention includes a driving power supply 1, a thermostat 2, an integrating sphere 3, an LED lamp holder 4 arranged on the thermostat 2, a spectrum analyzer 5, a computer 6 and a user For the driving power supply 1 that generates a small current, the signal transmission end of the spectrum analyzer 5 is connected to the computer 6, the probe reaches the inner wall through the integrating sphere 3, the driving power supply 1 is connected to the LED light source 7, and the LED light source 7 passes through the integrating sphere 3 One of the holes reaches the integrating sphere 3 , the driving power supply 1 is connected with the computer 6 , and the LED light source 7 is placed on the LED lamp holder 4 .

[0022] The forbidden band ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com