Method for designing axial travelling wave reactor starting area

A design method and technology of traveling wave reactor, applied in the field of start-up area structure of axial traveling wave reactor, can solve the problems of constant core reactivity and fluctuation of core reactivity, etc., to facilitate fuel management, maintain multiplication and The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

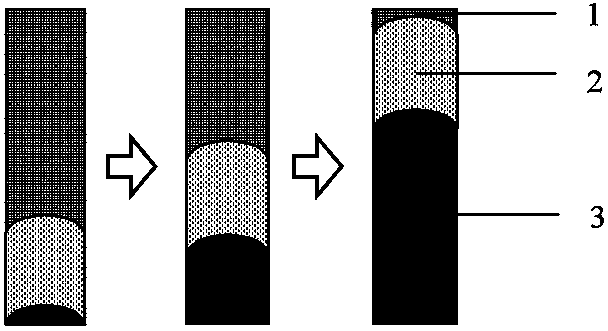

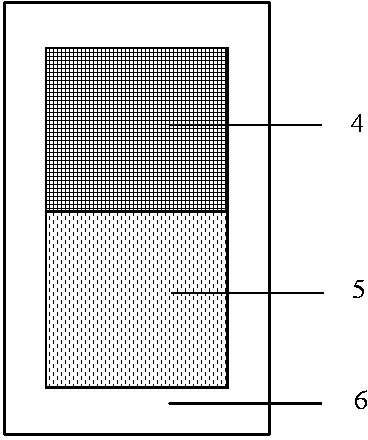

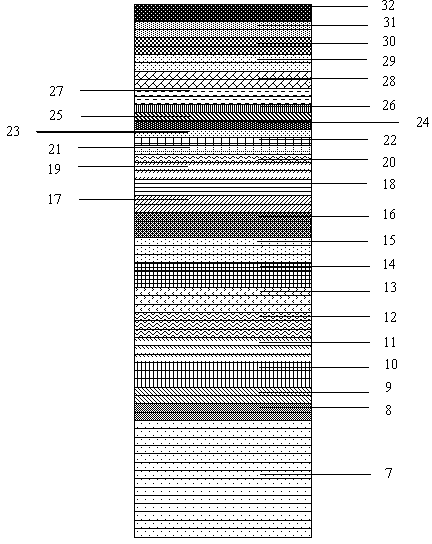

[0026] Such as Figures 1 to 5 The principle diagram shown is a design method of the start-up area of an axial traveling wave reactor according to the present invention. A core of an axial traveling wave reactor has been designed by using this method and has achieved remarkable results. The specific design scheme of the start-up area is as follows:

[0027] (a) The calculation found that after the important physical parameters of the axial traveling wave reactor, such as the axial power distribution, etc. are stabilized, the axial span is about 320cm, and the length of the start-up area is about the same as the span of the important physical parameters after stabilization, which is also taken as 320cm;

[0028] (b) In order to keep important physical parameters such as the shape of axial power distribution unchanged from the beginning of stacking to the end of its life, the stacking area is designed to be segmented in the axial direction. The smallest unit is 5cm, and each se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com