A kind of argon arc welding welding method after silver-plated aluminum tab

A technology of aluminum lug and welding method, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve problems such as blistering and blackening on the silver-plated surface, and affect the contact stability requirements of filter reactors, etc., to achieve Ensure heat dissipation, reduce foaming and blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] With reference to the accompanying drawings, the technical solution of the present invention is: an argon arc welding method for aluminum lugs after silver plating, which comprises the following steps:

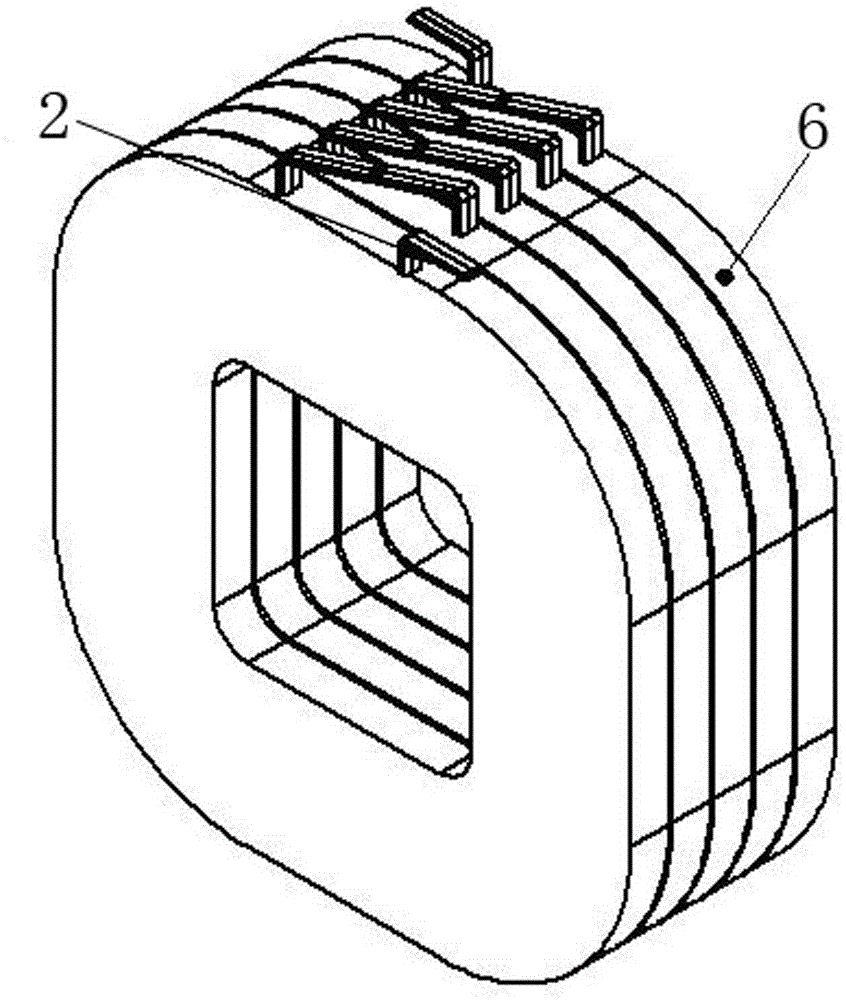

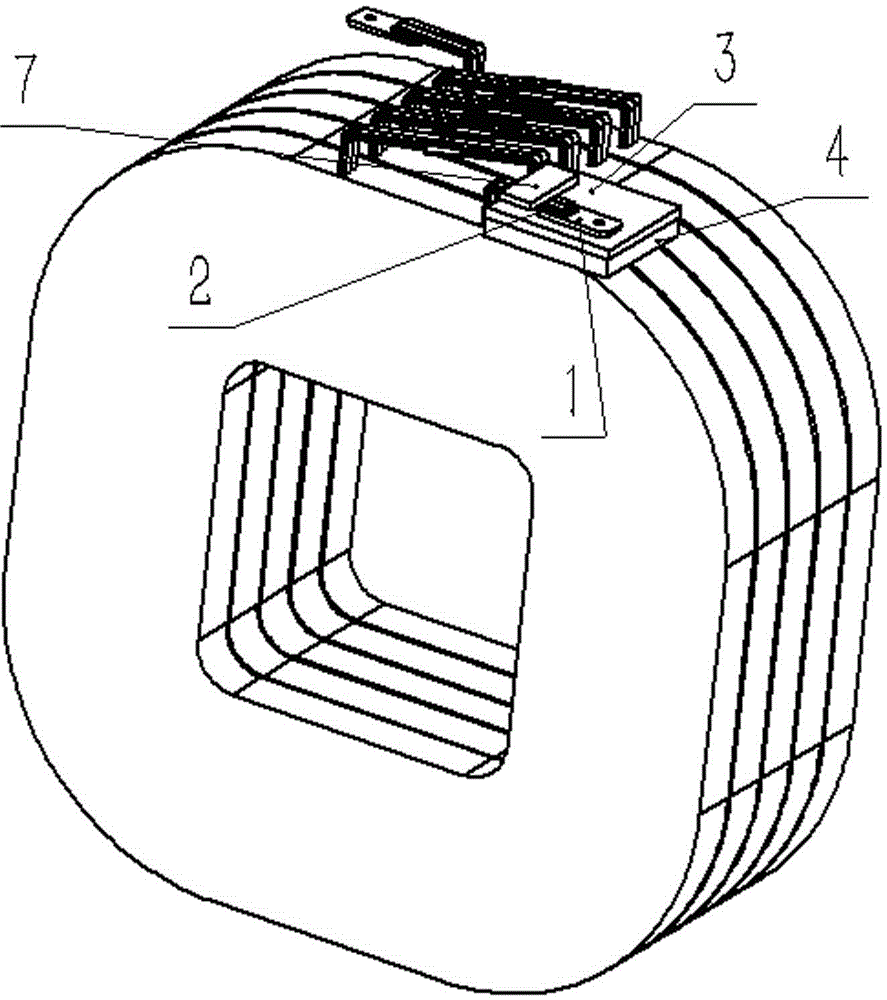

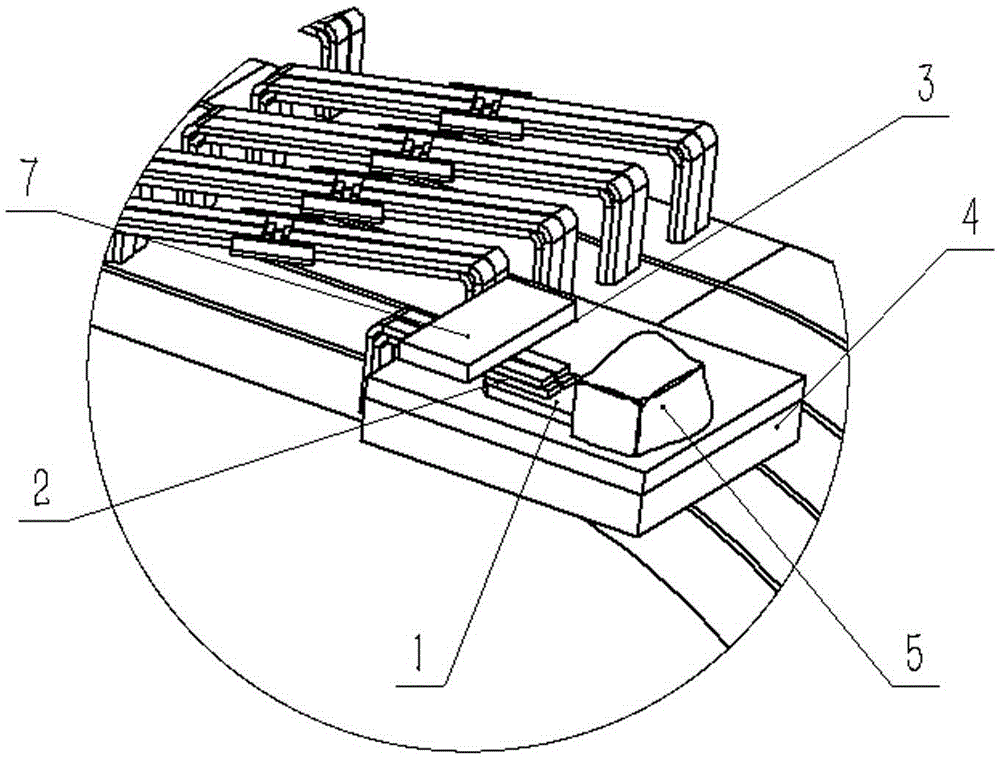

[0019] Step 1. Bend the coil outlet head 2 on the coil 6 flatly. When the coil 6 is a multi-core flat wire and wind it, it is required that after flat bending, the flattened coil outlet head of the coil outlet 2 is shorter than the lower layer of the wire outlet. Insulation and heat-resistant backing plate 4, metal conductive plate 3 and silver-plated aluminum lug 1 are placed in the lower part of the flattened coil outlet head 2 in sequence from bottom to top;

[0020] Step 2. Press the coil outlet head 2 from the upper part with a weight 7 until there is no gap between the coil outlet head 2, the silver-plated aluminum lug 1, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com