10kv moulding cable middle connector self-heating temperature controller and operation method

A cable intermediate head and automatic heating technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problem of shortening the baking time of the molded cable intermediate head, long production time of the molded cable intermediate head, and uneven heating of the cable insulation layer and other issues to achieve the effect of low work cost, easy observation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

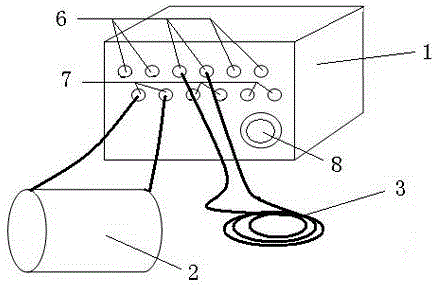

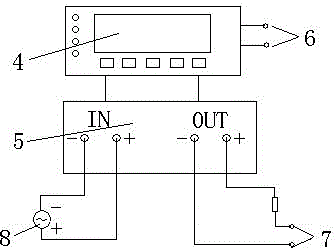

[0021] Such as figure 1 , 2 As shown, the automatic heating temperature controller for the middle head of a 10 kV molded cable is composed of a temperature control part and a mica heating ring 2. The temperature control part includes a k-type thermocouple 3 placed in the heating part and is connected to the temperature controller 1 through a wire. The temperature input port 6 and the temperature controller are connected to the mica heating coil 2 through the temperature control voltage output port 7 via wires. The temperature controller 1 includes a REX c-100 temperature controller 4 connected to a solid state relay 5 and a voltage temperature input port 6 respectively, and the solid state relay 5 is connected to a power input terminal 8 and a temperature control voltage output port 7 respectively.

[0022] The present invention is applied to the Dandong supply port area, and the actual operation experiment by the second shift of the power distribution and inspection of the D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com