Concentrating photovoltaic power generation light guide funnel module

A technology of concentrating photovoltaic and light funnel, which is applied in the field of solar power generation, can solve the problems of low processing efficiency, increased weight, complicated process, etc., and achieves the effects of improving processing efficiency, simple product structure, and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

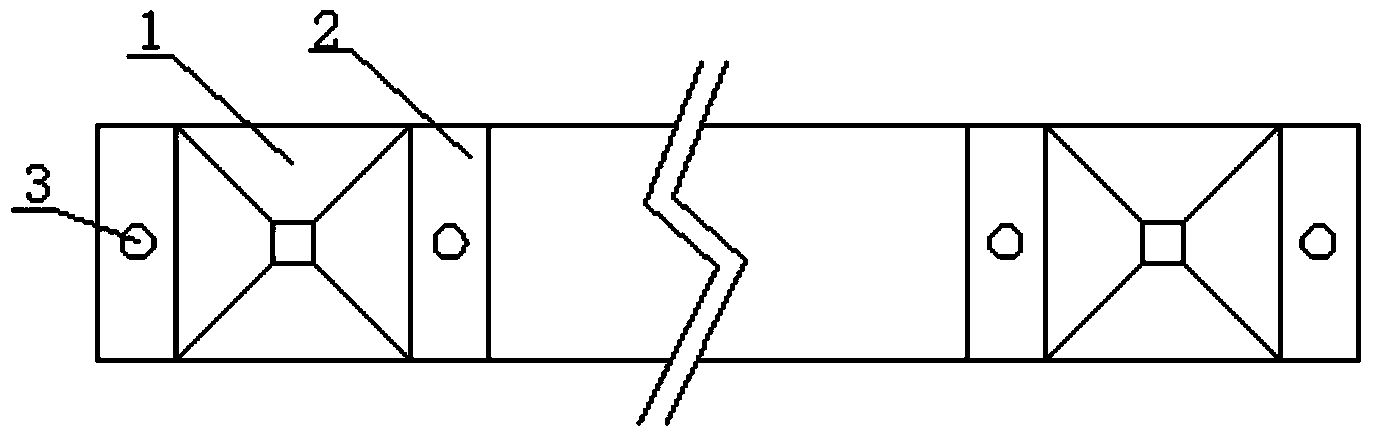

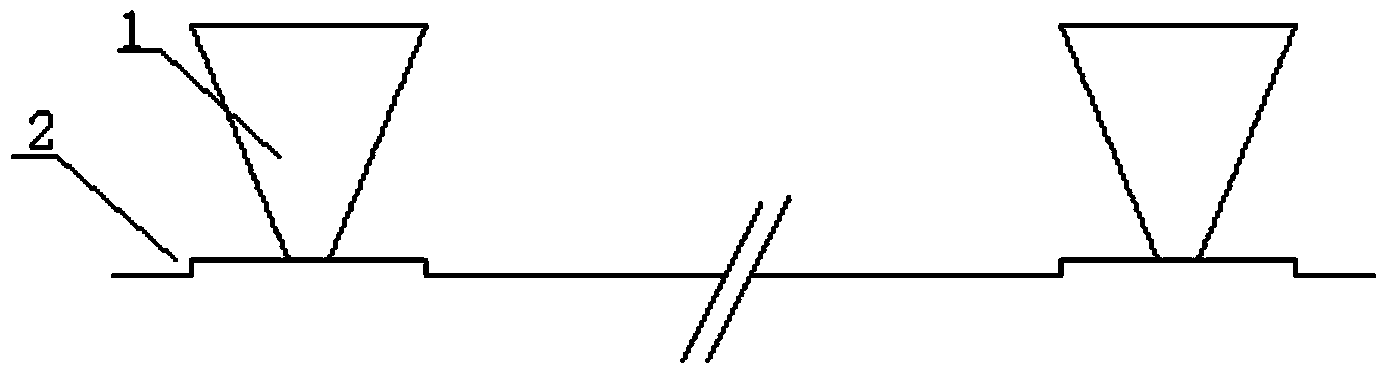

[0014] A concentrating photovoltaic power generation light guide funnel module, such as Figure 1~2 As shown, it includes a light guide funnel 1, a connection plate 2 and a fixed installation hole 3, the lower port of the light guide funnel 1 is directly welded on the connection plate 2, and two opposite surfaces of the connection plate 2 are provided with two The mounting holes 3 are fixed, and the connecting plate 2 connects a plurality of light guiding funnels 1 together. The light guiding funnel 1 is a tapered metal material component, including two upper and lower ports and four isosceles trapezoidal sides, the area of the upper port is larger than the area of the lower port, and the light guiding funnel 1 is more than two ; The shape and size of the lower port of the light guiding funnel 1 are exactly the same as the shape and size of the effective surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com