Vehicle interior board and manufacturing method therefor

A technology for automotive interior panels and manufacturing methods, applied to chemical instruments and methods, vehicle parts, layered products, etc., can solve the problems of damaging the appearance of products and reducing the flatness of the plank surface, so as to improve productivity and simplify production processes , control the effect of poor assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, an automobile interior panel according to an embodiment of the present invention will be specifically described with reference to the drawings.

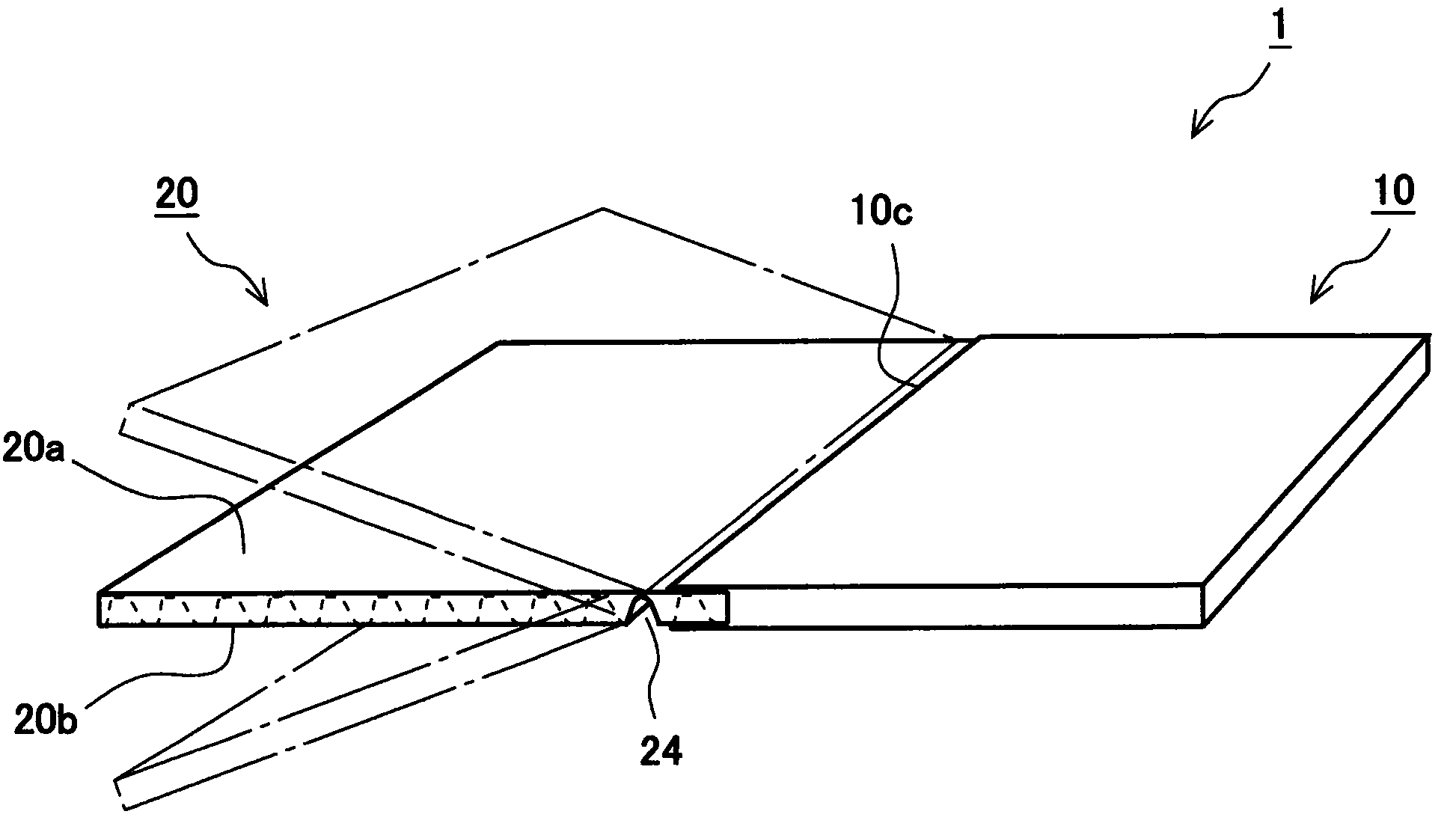

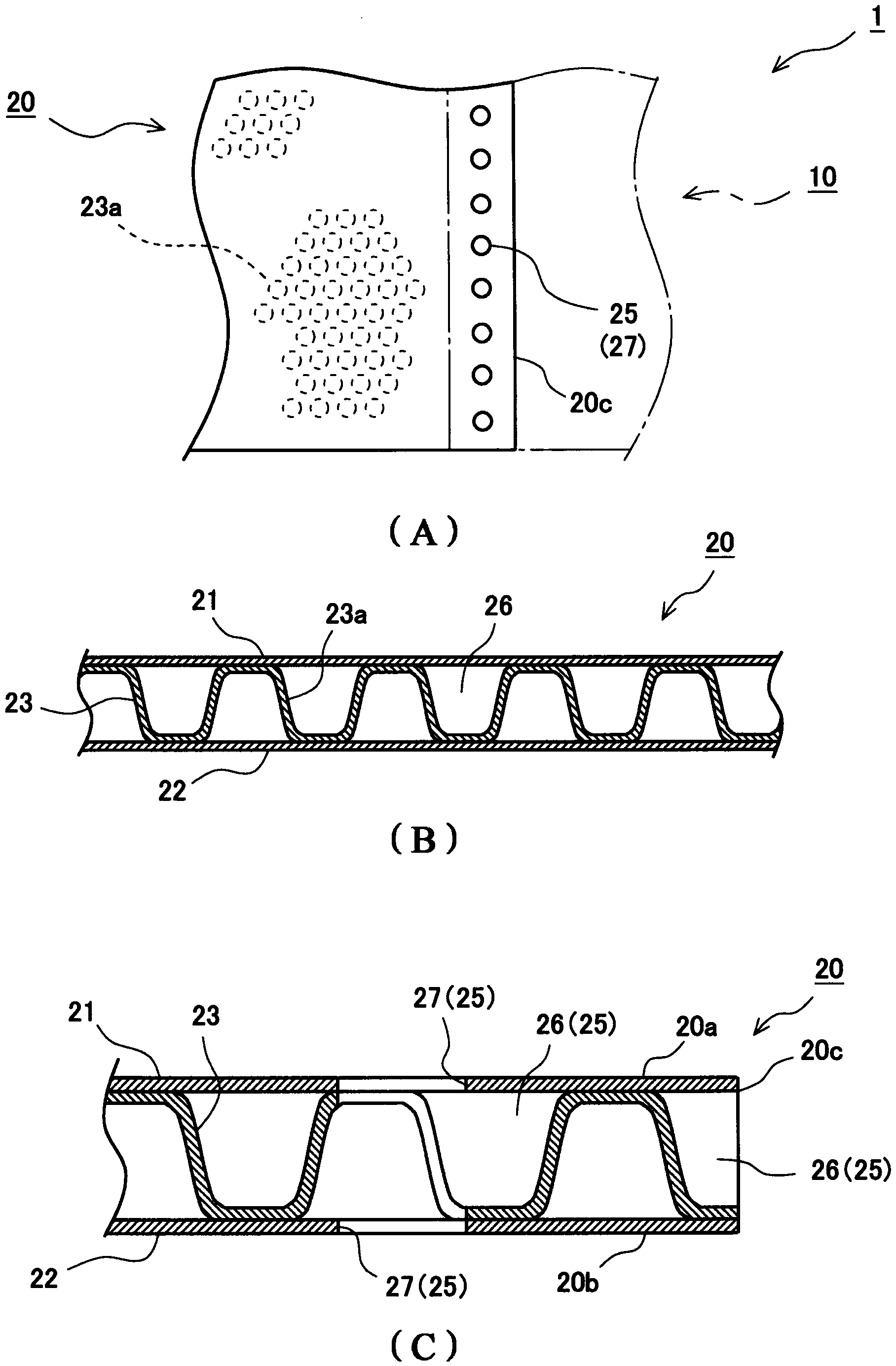

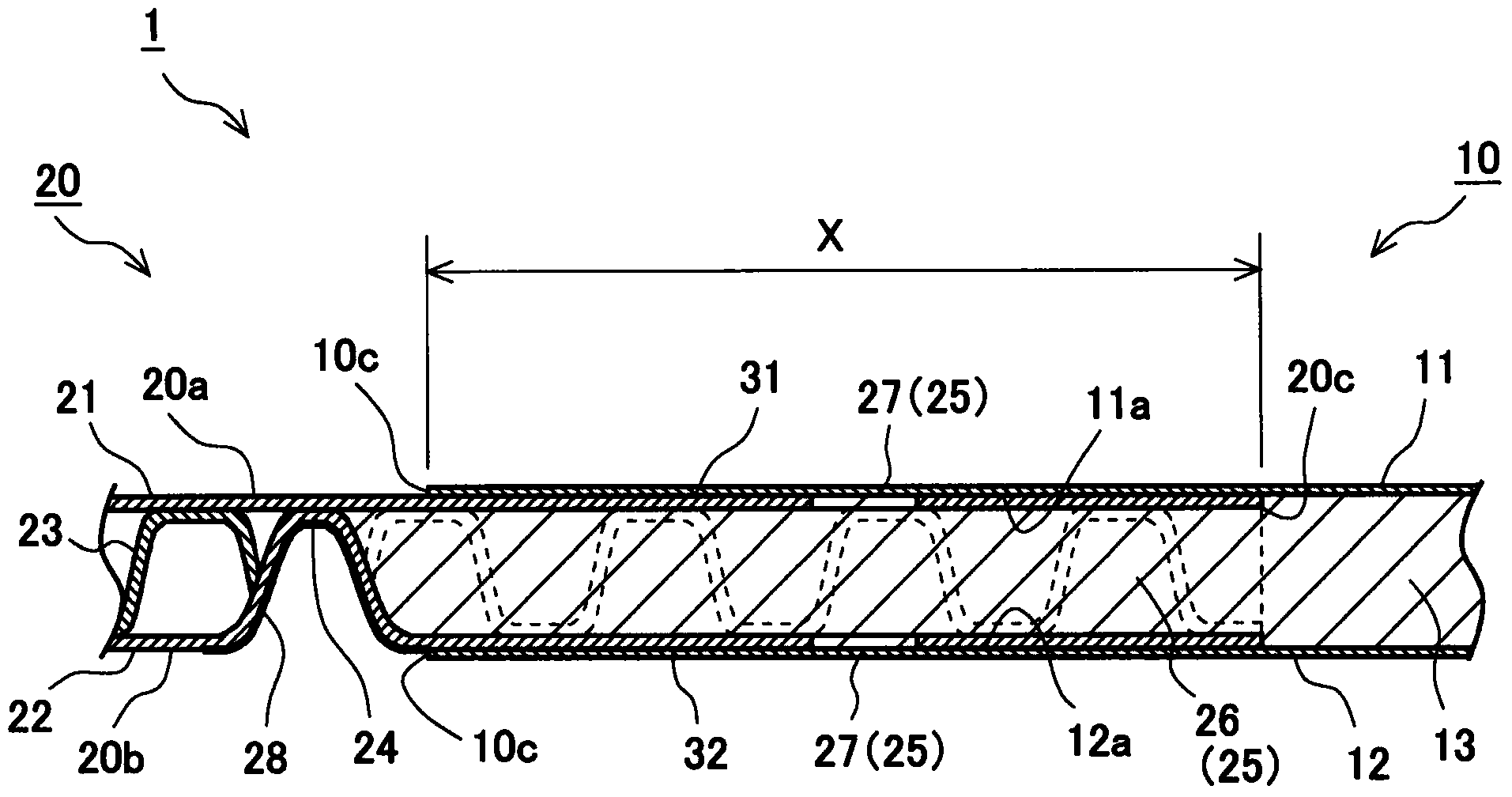

[0031] First, refer to figure 1 or image 3 , specifically explain the structure of the automotive interior panel 1. figure 1 It is a perspective view schematically showing a brief structure of the automotive interior panel 1 . The automobile interior panel 1 is used, for example, as a floor of a cargo compartment of an automobile. According to the application, the automotive interior panel 1 is molded into a predetermined peripheral shape.

[0032] Such as figure 1 As shown, the automotive interior trim panel 1 is formed by connecting the first floor board 10 and the second floor board 20 . A groove 24 is formed on one main surface 20 b of the second plank 20 . The groove 24 extends linearly along the end 10c of the first plank 10 . In this way, the groove 24 can be used as a hinge portion to bend the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com