Preparation method of ginger and soybean cheese

A soybean and ginger technology, applied in the field of food processing, can solve problems such as lack of coagulant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

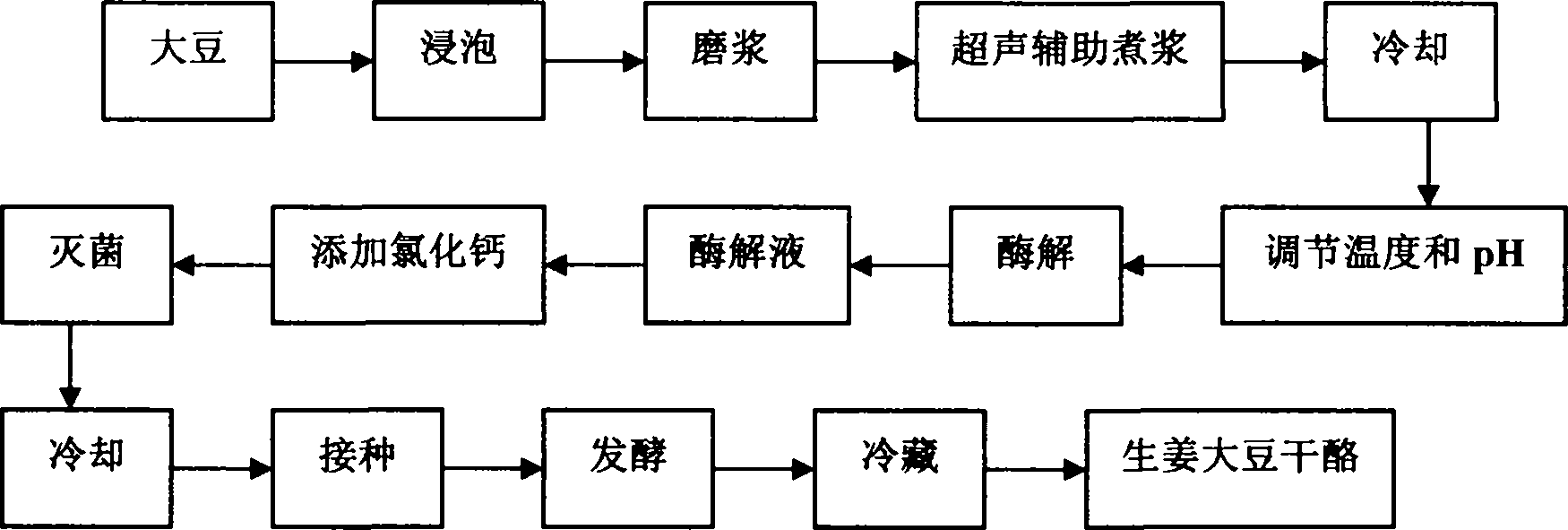

Image

Examples

preparation example Construction

[0013] A preparation method of ginger soybean cheese, the method comprises the following steps: (1) soaking soybeans and then grinding to obtain soybean milk, and performing ultrasonic-assisted cooking of the soybean milk, the ultrasonic power is 100-500W, and the boiling temperature is 80-100 ℃, the cooking time is 5-10min; (2) cooling after cooking, adjusting the temperature and pH of the soybean milk, and then adding the protease extracted from ginger for enzymatic hydrolysis to obtain an enzymatic hydrolyzate solution, the amount of ginger protease added It is 1-3% of the mass of soybean milk, the enzymatic hydrolysis temperature is 55-65 ℃, and the enzymatic hydrolysis time is 1-3 h; (3) 2mmol / L calcium chloride is added to the enzymatic hydrolysis solution, and then the enzymatic hydrolysis solution is sterilized , After cooling, access to Lactobacillus bulgaricus and Streptococcus thermophilus for fermentation, the ratio of the Lactobacillus bulgaricus to Streptococcus t...

Embodiment 1

[0018] Soybeans are soaked and then milled to obtain soymilk. Under the condition of ultrasonic power of 400W and boiling temperature of 90°C, the soybean milk is subjected to ultrasonic-assisted cooking for 8 minutes, cooled after cooking, and the temperature and pH of the soymilk are adjusted. Under the condition of 60 °C, add 2% ginger protease for enzymatic hydrolysis for 1.5 hours to obtain an enzymatic hydrolysis solution, add 2 mmol / L calcium chloride to the enzymatic hydrolysis solution, and then sterilize and cool the enzymatic hydrolysis solution. Under the conditions of 4% and 37°C fermentation temperature, Lactobacillus bulgaricus and Streptococcus thermophilus with a compound ratio of 1:1 were added for fermentation for 50min, and then the ginger soybean cheese was obtained by refrigerating at 4°C for 12h after fermentation.

Embodiment 2

[0020] Soybeans are soaked and then milled to obtain soymilk. Under the conditions of ultrasonic power of 300W and boiling temperature of 95°C, the soybean milk is subjected to ultrasonic-assisted cooking for 9 minutes, cooled after cooking, and the temperature and pH of the soymilk are adjusted. Under the condition of 55 ℃, add 2% ginger protease for enzymatic hydrolysis for 2 hours to obtain an enzymatic hydrolysis solution, add 2 mmol / L calcium chloride to the enzymatic hydrolysis solution, and then sterilize and cool the enzymatic hydrolysis solution. 5%, under the condition of fermentation temperature of 36°C, adding Lactobacillus bulgaricus and Streptococcus thermophilus with a compound ratio of 1:1 for fermentation for 40min, and refrigerating at 4°C for 12h after fermentation to obtain ginger soybean cheese.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com