Production system of definite elongation wire

A technology of production system and constant stretch line, which is applied to the surface coating liquid device, pretreatment surface, coating and other directions, which can solve the problems that the constant stretch effect of the glass fiber filament constant stretch line is not good enough, and achieve the constant stretch effect Good, uniform adhesive layer thickness, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

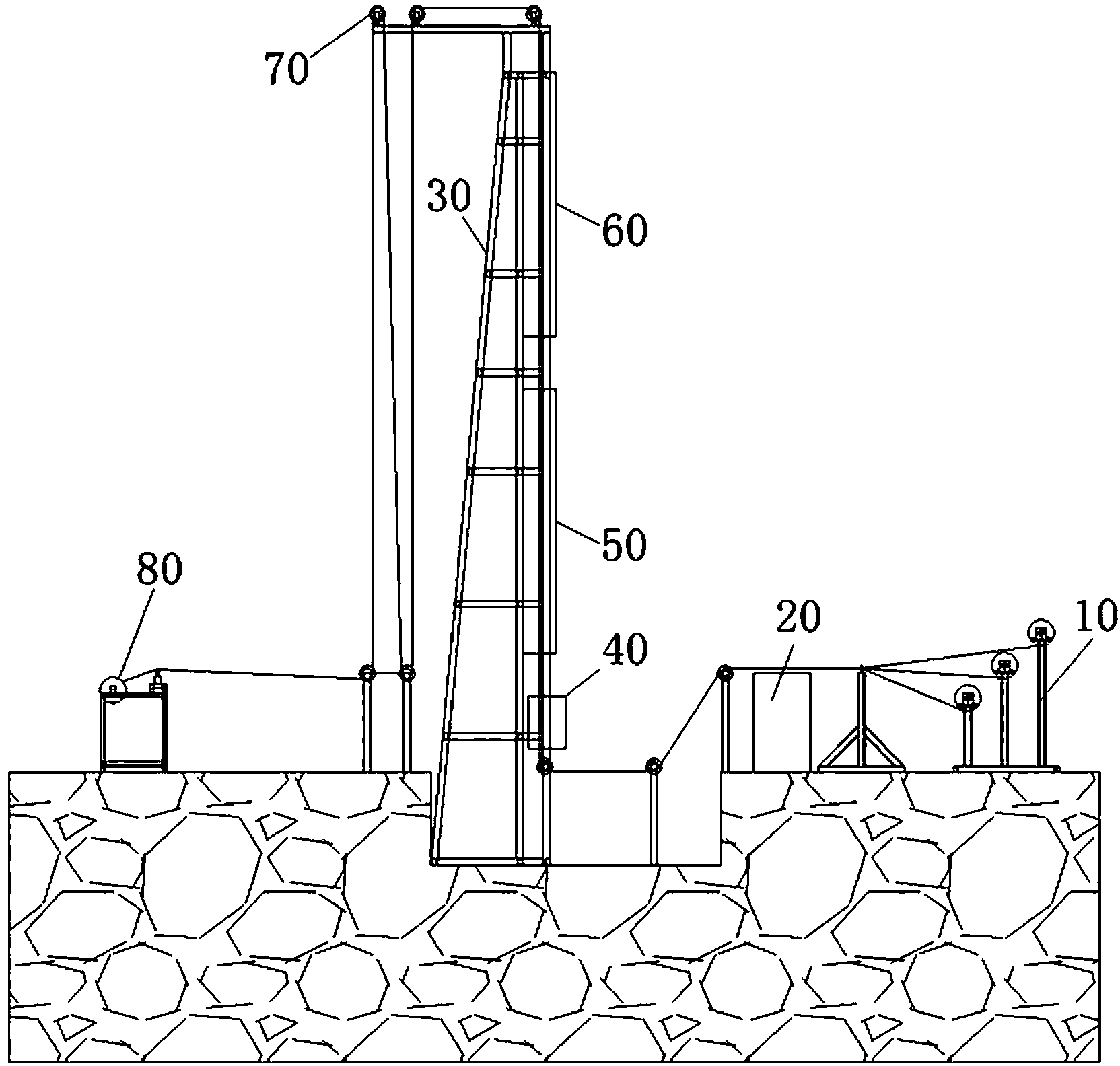

[0023] Such as image 3 As shown, a production system for a fixed stretch line includes a pay-off machine 10, a cleaning machine 20, an upright mounting frame 30, a dip coating device 40, an upright lower drying tunnel 50, an upright upper drying tunnel 60, and cooling rollers. Group 70 and wire take-up machine 80, cleaning machine 20 is arranged on the front side of pay-off machine 10, and upright mounting frame 30 is arranged on the front side of cleaning machine 20, dip coating equipment 40, lower section drying channel 50, upper section drying channel 60 from the bottom To be installed on the vertical installation frame 30 successively, the vertical installation frame 30 is respectively provided with the wire-in guide wheel and the wire-out guide wheel under the dipping equipment 40 and above the upper part of the drying tunnel 60, and the cooling roller group 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com