Automatic slot milling machine

An automatic and machine tool technology, applied in the field of CNC machine tools, can solve the problems of low labor intensity of operators, good appearance quality of milling surface, and high production efficiency, and achieve the effect of low labor intensity, good appearance quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

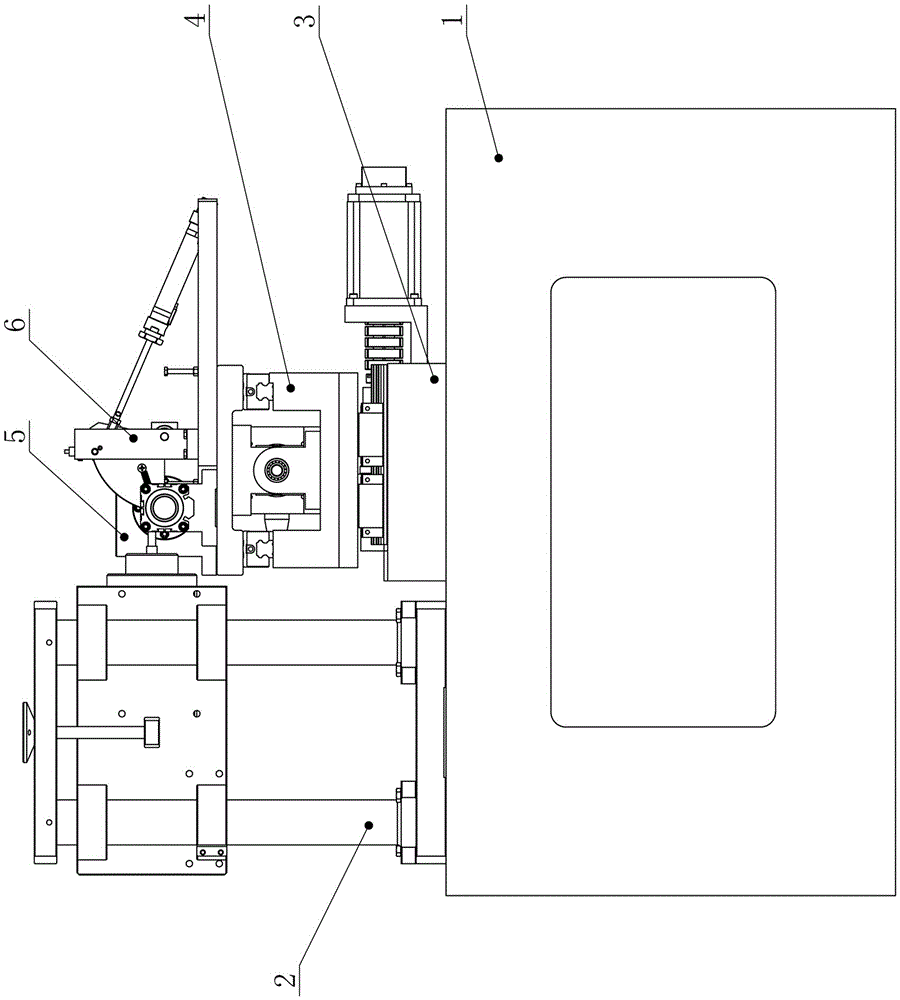

[0044] Refer to attached Figure 1-13 , The automatic slot milling machine tool is composed of a bed 1, a lifting moving part 2, a forward and backward moving part 3, a left and right moving part 4, a rotary fixture part 5, and an automatic feeding part 6.

[0045] The bed 1 is a casting machine body.

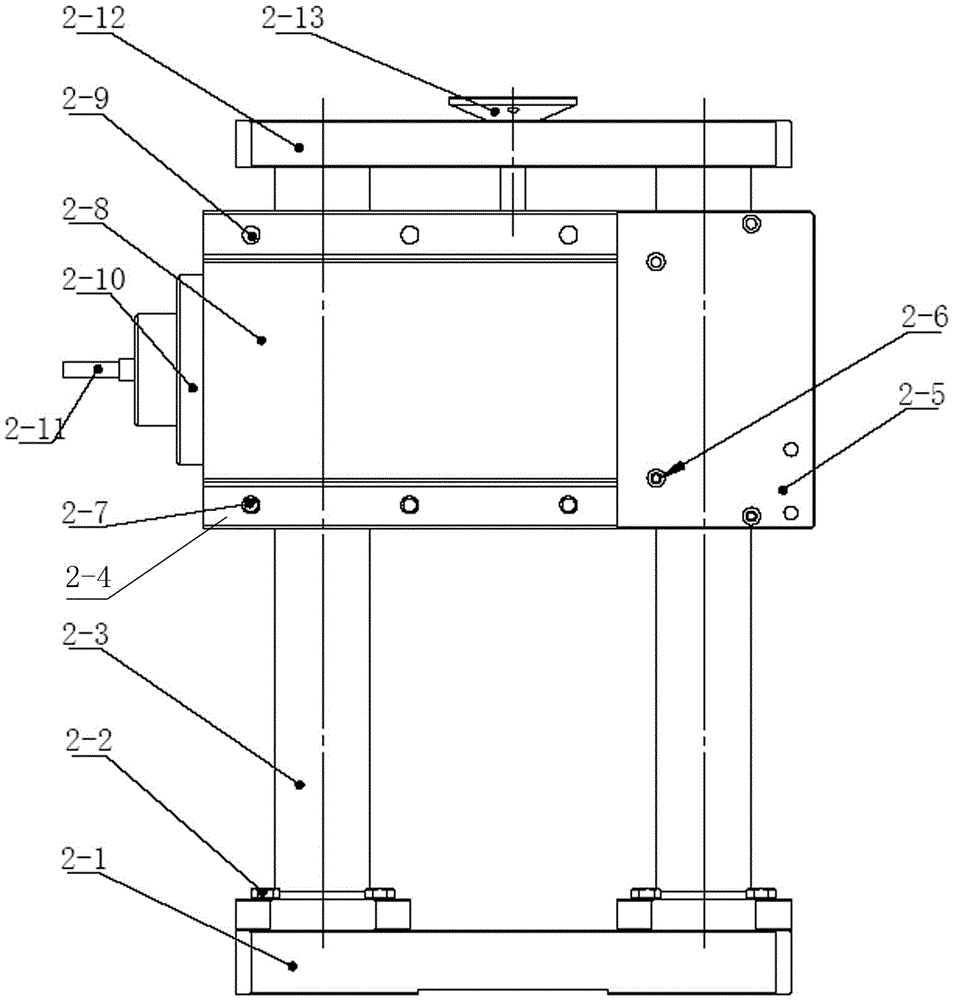

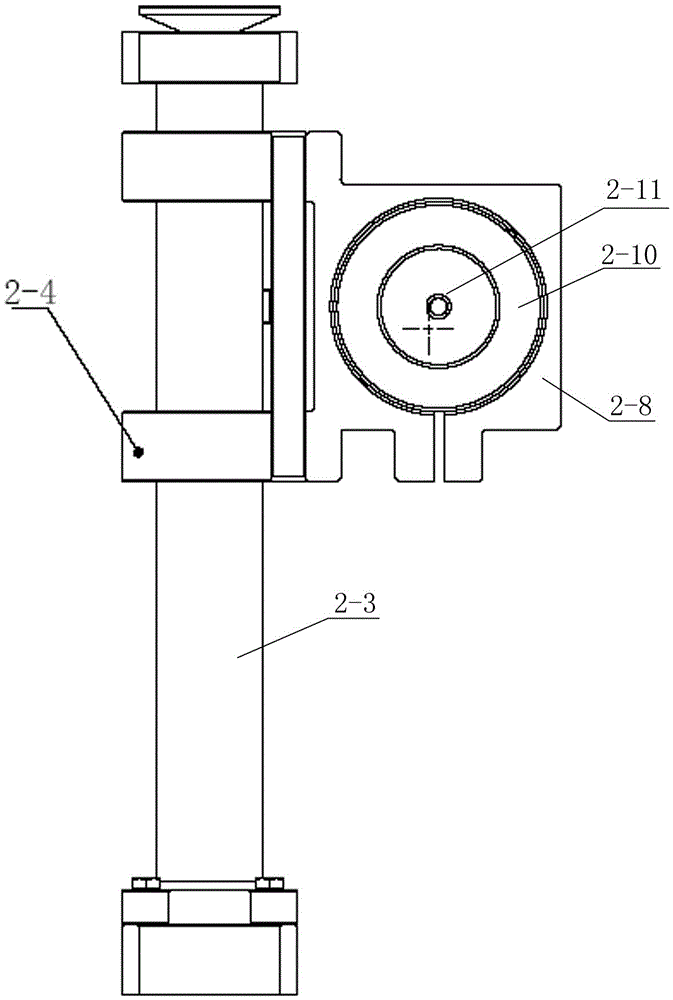

[0046] The lifting moving part 2 is installed on the top of the bed 1 . The lifting and moving part 2 includes a column bottom plate 2-1, two columns 2-3, 4 guide sleeves 2-4, a lifting mounting plate 2-5, a grinding head seat 2-8, an electric spindle 2-10, a milling cutter 2-11, top plate 2-12, lifting screw mandrel 2-13.

[0047] Among them, the two columns 2-3 are fixed on the column bottom plate 2-1 through 8 hexagonal bolts 2-2; the upper parts of the two columns 2-3 are connected with the top plate 2-12; the lifting mounting plate 2-5 is passed through 8 inner hexagon cylinder heads The screws 2-6 are fixed on the sides of four guide sleeves 2-4, and the guide sleeves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com