A new type of multifunctional welding rod insulation cylinder

A welding rod heat preservation and multi-functional technology, which is applied to welding equipment, welding accessories, auxiliary welding equipment, etc., can solve the problems of easily damaged insulation cylinder cover fasteners, difficult to remove small-diameter welding rods, and difficult to place insulation cylinders, etc. effect, efficient use of resources, and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

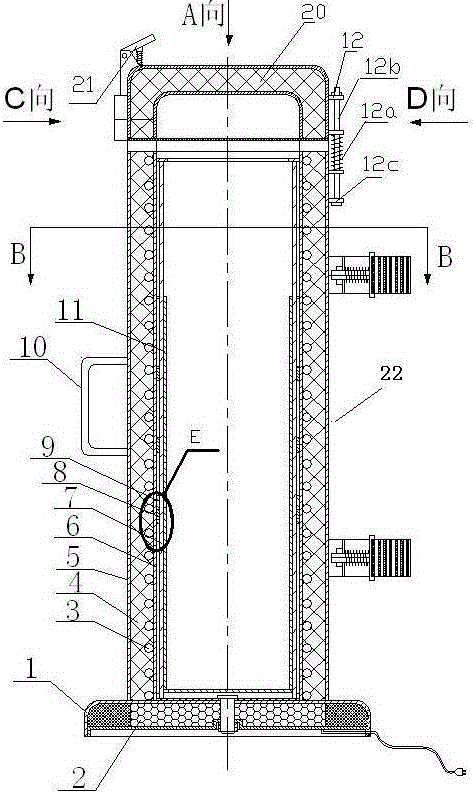

[0030] In order to overcome the problems in the prior art that the fastener of the welding rod heat preservation cylinder cover is easily damaged, the heat preservation effect is low, the small diameter electrode is not easy to take out, and the heat preservation cylinder is difficult to place on the cylinder body 22 . The invention provides a novel multifunctional welding rod insulation cylinder, such as figure 1 As shown, a cylinder 22 is included, a handle 10 is provided on the side wall of the cylinder 22, a cylinder cover 20 and a base 1 are respectively installed on the top and bottom of the cylinder 22, and the cylinder 22 is formed by the insulation cylinder shell 5 and placed Insulation cylinder shell 5 is composed of insulation cylinder liner 6, the base 1 is provided with a first heater 2, the gap between insulation cylinder shell 5 and insulation cylinder liner 6 is provided with a second heating wire 3, the second A heater 2 and a second heating wire 3 are respect...

Embodiment 2

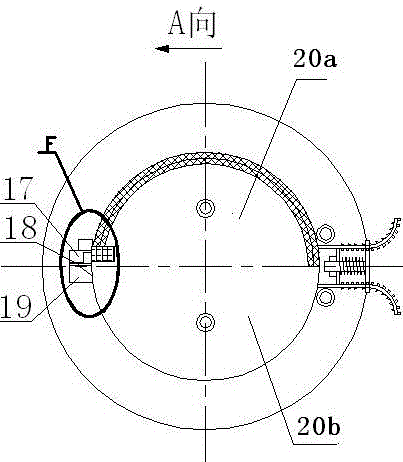

[0032] In order to solve the problems that the existing welding rod heat preservation cylinder cover is easily damaged, inconvenient to operate and poor heat preservation effect, the present invention changes the structure that the original welding rod heat preservation cylinder cover is turned up and down by 180 degrees and fastened by fastening parts, such as figure 1 , 3 , Shown in 4, the inner wall of the cylinder cover 20 and the outer wall of the top of the cylinder body 22 are screwed together to facilitate the removal of the cylinder cover 20 to store the welding rod. The cylinder cover 20 is divided into two parts, including a semicircular cylinder cover a20a and a semicircular cylinder cover b20b, and a pressing part 21 is fixed above the semicircular end of the cylinder cover a20a; It consists of two parts, including the upper cover b120b1 and the lower cover b220b2.

[0033] Such as figure 1 and Figure 4 As shown, the cylinder cover connector 12 includes a rota...

Embodiment 3

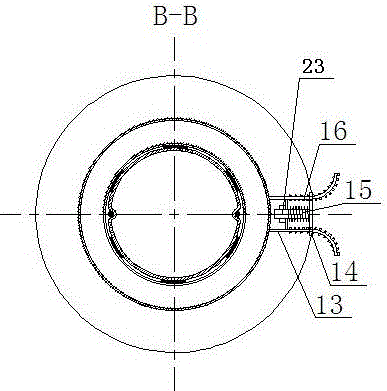

[0038] In order to solve the problem that the welding rod insulation cylinder is easy to fall and cause damage when working at high altitudes, a magnetic suction type tightener is provided on one side of the cylinder body 22 to fix the insulation cylinder and prevent it from falling, such as figure 2 As shown, the magnetic suction type tightener is composed of a spring b15, an adjustment plate 14, a magnet and two flexible steel strips 13 fixed on the cylinder 22; the two flexible steel strips 13 are on the same horizontal plane Inside and perpendicular to the side of cylinder body 22, two flexible steel strips 13 respectively pass through the two ends of adjusting plate 14 and are fixed on cylinder body 22; said spring b15 is arranged between two flexible steel strips 13 and one end It is fixedly connected with the adjusting plate 14, and the other end is connected with the fixed block 23 fixedly connected between the two flexible steel strips 13; the outer sides of the two f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com