Supercritical CO2 extraction method for chimonanthus praecox essential oil

A carbon dioxide and supercritical technology, applied in essential oils/spices, fat production, etc., can solve problems such as high temperature, cooking odor of wintersweet essential oil, hidden dangers of organic solvent extraction, etc., to save resources, no safety hazards, and fast extraction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

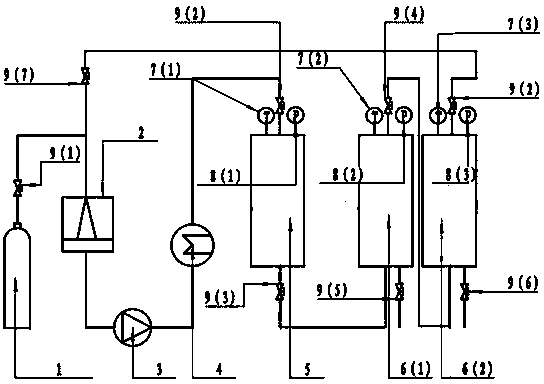

Image

Examples

Embodiment 1

[0009] Embodiment 1: a kind of method of supercritical carbon dioxide extraction wintersweet essential oil, get the wintersweet flower 100g that water content is 70% after pretreatment and put into extraction kettle, open carbon dioxide cylinder, carbon dioxide passes through condenser, high-pressure pump and heater successively Enter the extraction kettle to extract the wintersweet flower. The pressure in the extraction kettle is 20Mpa, the temperature is 45°C, and the flow of carbon dioxide is 25 kg / h; Two-stage decompression separation was carried out in the secondary analytical kettle, and the circulation time of carbon dioxide was 1.5 hours. The crude wintersweet essential oil was centrifuged by a centrifuge with a speed of 1000 r / min for 2 minutes, and finally 1.213 g of pure essential oil was obtained; The pressure in the first desorption tank is 6MPa and the temperature is 30°C, the pressure in the second desorption tank is 3MPa and the temperature is 25°C.

Embodiment 2

[0010] Embodiment 2: a kind of method of supercritical carbon dioxide extraction wintersweet essential oil, get the wintersweet flower 100g that water content is 70% after pretreatment and put into extraction kettle, open carbon dioxide cylinder, carbon dioxide passes through condenser, high-pressure pump and heater successively Enter the extraction kettle to extract the wintersweet flower. The pressure in the extraction kettle is 40Mpa, the temperature is 60°C, and the flow of carbon dioxide is 20 kg / h; Two-stage decompression separation was carried out in the second analytical kettle, the circulation time of carbon dioxide was 2 hours, and the crude wintersweet essential oil was centrifuged by a centrifuge with a speed of 1000 r / min for 2 minutes, and finally 1.258 g of pure essential oil was obtained; The pressure in the first desorption tank is 5MPa and the temperature is 30°C, the pressure in the second desorption tank is 5MPa and the temperature is 25°C.

Embodiment 3

[0011] Embodiment 3: a kind of method of supercritical carbon dioxide extraction wintersweet essential oil, get the wintersweet flower 100g that water content is 70% after pretreatment and put into extraction kettle, open carbon dioxide cylinder, carbon dioxide passes through condenser, high-pressure pump and heater successively Enter the extraction kettle to extract the wintersweet flower. The pressure in the extraction kettle is 30Mpa, the temperature is 30°C, and the flow rate of carbon dioxide is 30 kg / h; Two-stage decompression separation was carried out in the second analytical kettle, and carbon dioxide was added for separation. The circulation time of carbon dioxide was 2 hours, and the crude wintersweet essential oil was centrifuged by a centrifuge with a speed of 1000 r / min for 2 min. 1.116g of pure essential oil was obtained; the pressure in the first desorption tank was 8MPa and the temperature was 30°C, and the pressure in the second desorption tank was 1MPa and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com