Once-closure and staging-closure combined dam type power plant construction diversion method

A technology for construction diversion and hydropower stations, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of wide and narrow river channels, poor adaptability of longitudinal cofferdams to unknown geological conditions, long power generation construction period, etc., to achieve The effects of reducing technical difficulty and risk, shortening the power generation period, and saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

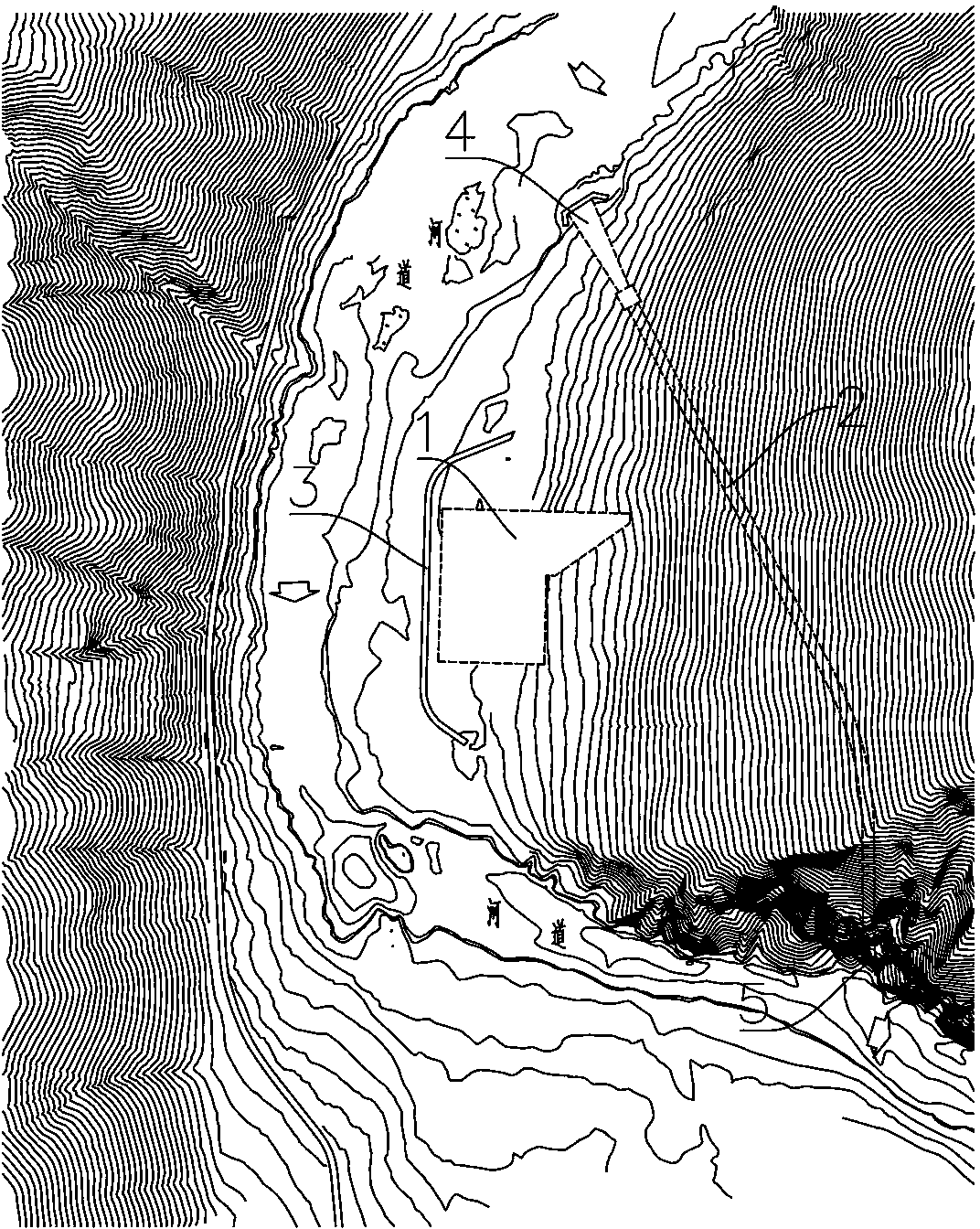

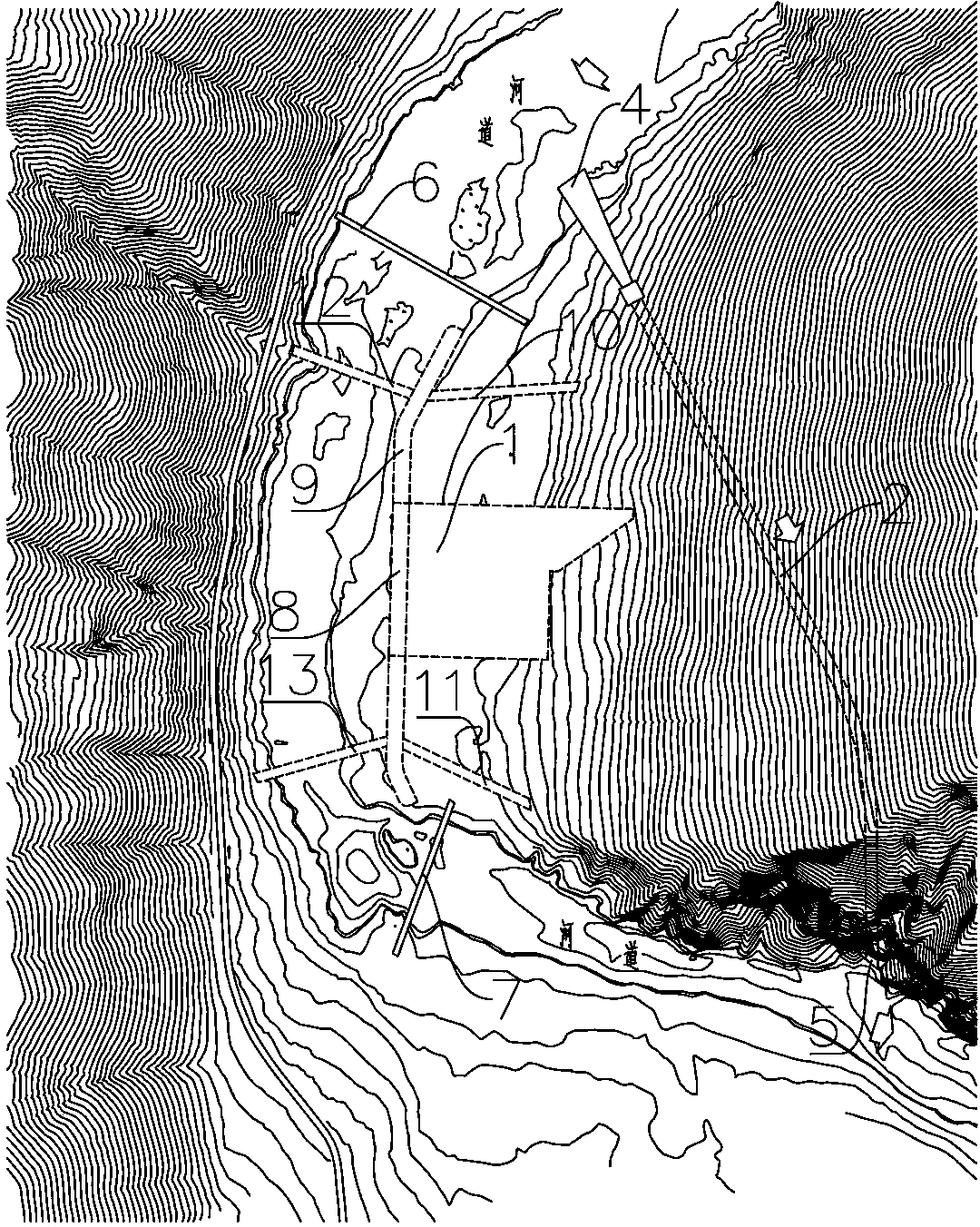

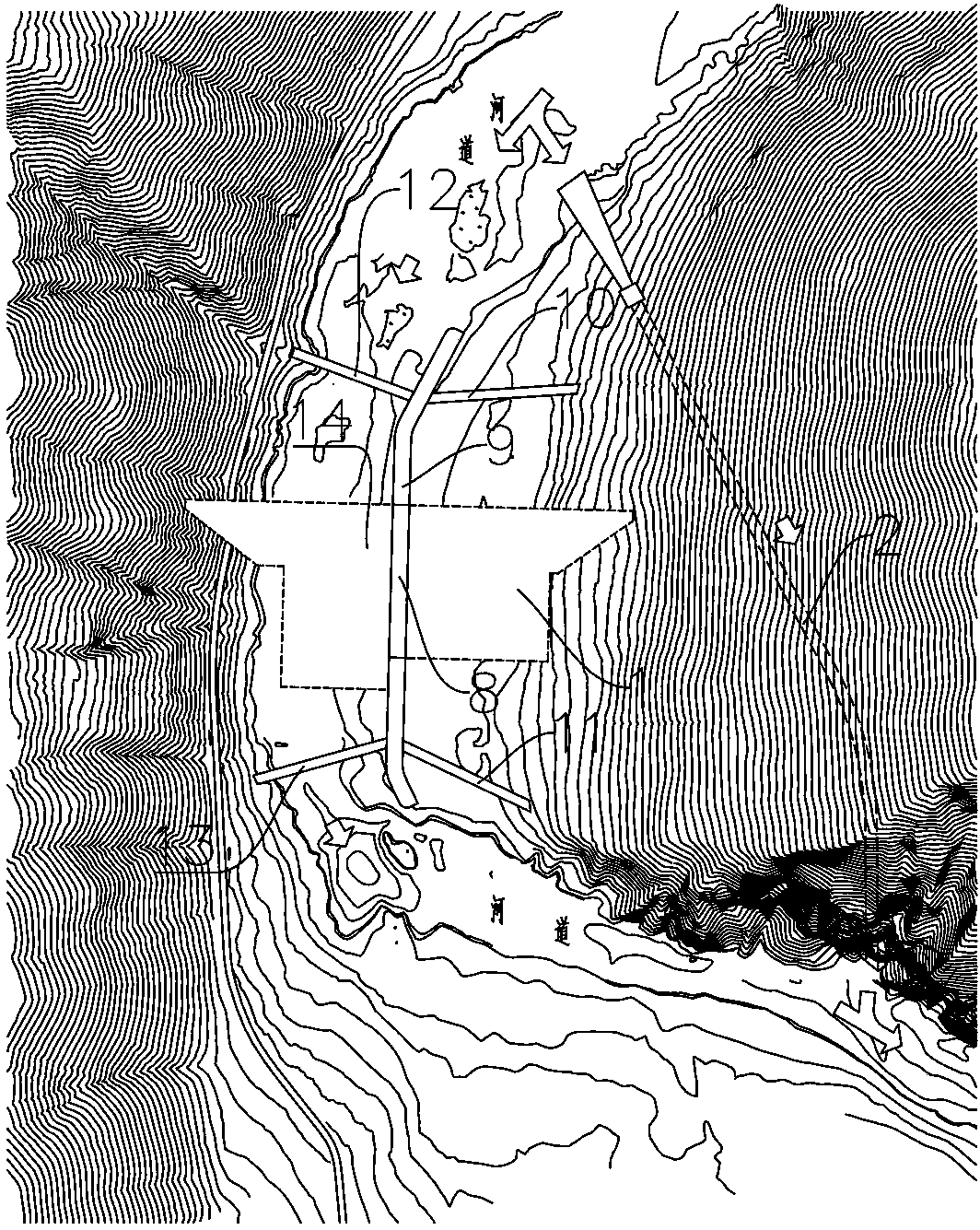

[0023] This embodiment is a construction diversion method for a dam-type hydropower station combining one-time interception and staged interception. The specific construction sequence and method are as follows:

[0024] a. Build an inlet cofferdam 4 and an outlet cofferdam 5 at the inlet and outlet positions of the diversion tunnel 2 to be built on one bank of the river;

[0025] b. If figure 1 As shown, the diversion tunnel 2 is built under the protection of the inlet cofferdam 4 and the outlet cofferdam 5; while the diversion tunnel 2 is being built, a temporary cofferdam 3 is set up at the position of the first-stage foundation pit 1 to be excavated on one bank of the river ( along the direction of the water flow), part of the first-stage foundation pit 1 was excavated under the maintenance of the temporary cofferdam, and part of the power plant behind the dam of the key project of the project was built in the part of the first-stage foundation pit excavated during the dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com