Prestressed double laminated wood beam

A prestressed, double-spliced beam technology, applied in joists, girders, trusses, etc., can solve problems such as insufficient strength to be fully exerted, and achieve the effects of beautiful appearance, improved ductility, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

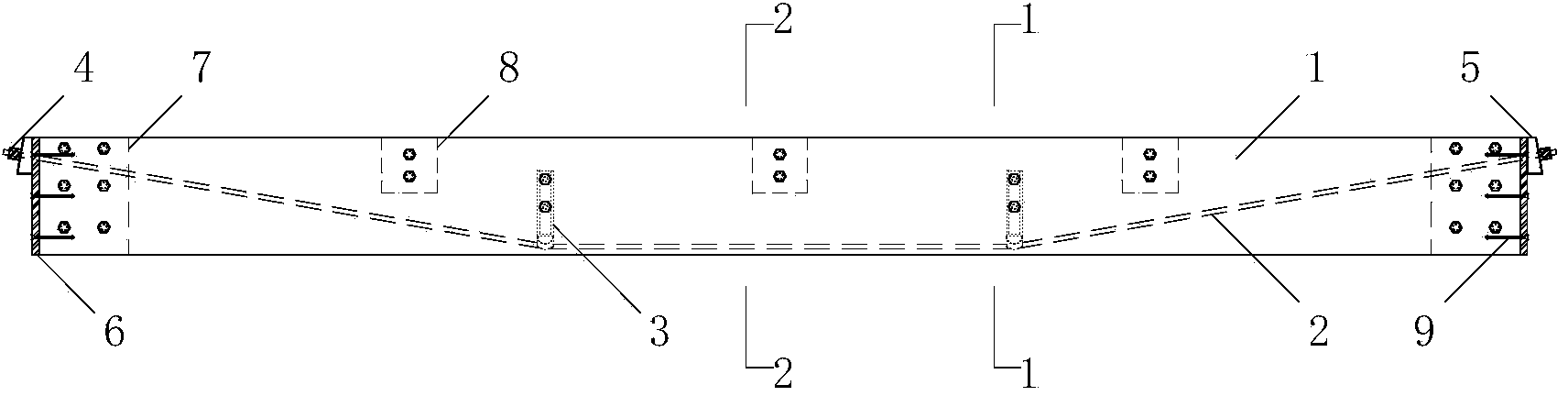

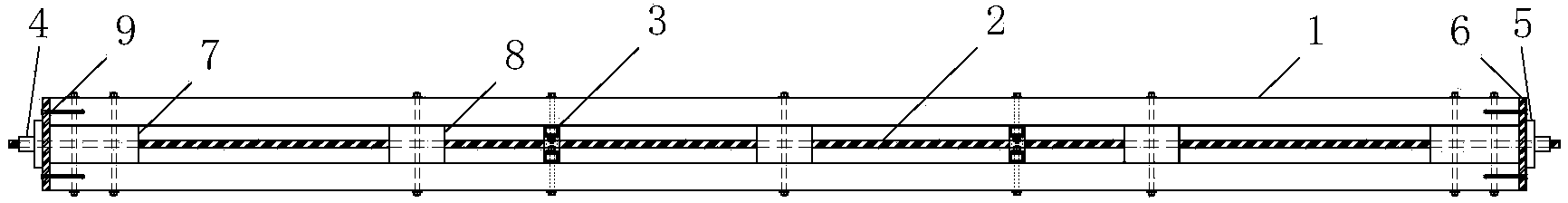

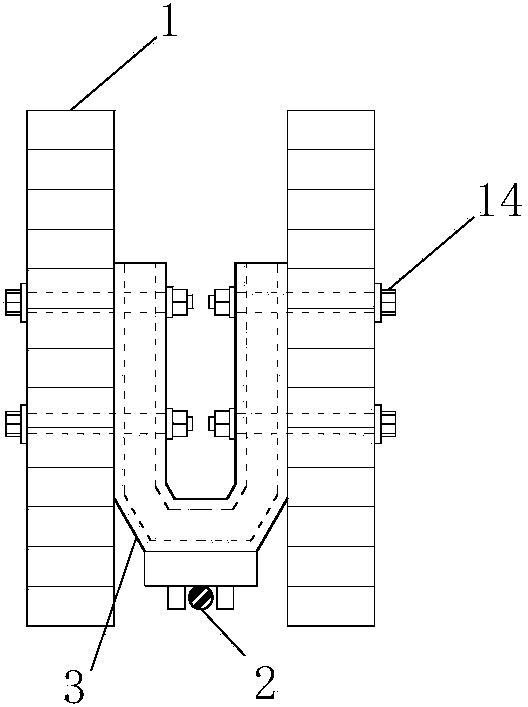

[0037] Such as Figure 1-8 Shown: a prestressed double glued wood beam, including wooden beam main body 1, prestressed tendon 2, steering device 3, anchorage 4, steel pad 5, anchor pad 6, beam end pad 7, span Pad block 8 and self-tapping screw 9, described wooden beam main body 1 is a double-joint beam, and the double-split beam is connected as a whole by beam end pad 7 and span pad 8 arranged at intervals along the full length of the component, and beam end pad 7, The spacer 8 is connected with the wooden beam main body 1 by fixing the spacer bolt 15 . The prestressed tendons are set 2 in the middle gap of the double-split beam, and the two ends of the prestressed tendons 2 are anchored to the beam end through the anchor 4 and the anchor backing plate 6, and the beam end is provided with a beam for anchoring the anchor backing plate. The end screw hole 10 and the prestressed tendon hole 11 are reserved at the beam end, the anchor backing plate 6 is provided with the anchor b...

Embodiment 2

[0039] Such as Figure 7-9 As shown, the difference between this embodiment and Embodiment 1 is that: the wooden beam main body 1 is a box-shaped beam, and the prestressed tendons 2 are arranged in the hollow space of the box-shaped beam.

Embodiment 3

[0041] Such as Figure 10-12 As shown, the difference between this embodiment and Embodiment 1 is that the supporting body 3-1 of the steering device 3 is rectangular.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap