Separate elastic temperature sensor

A temperature sensor, separate technology, used in thermometers, thermometer parts, instruments, etc., can solve the problems of large installation space, poor motor operating conditions, limited space, etc., to optimize the assembly manufacturing method, and the anti-vibration effect is remarkable. , the effect of accurate bearing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

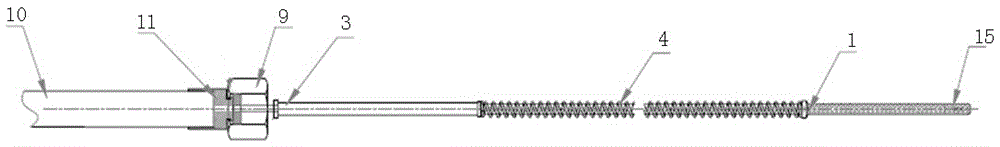

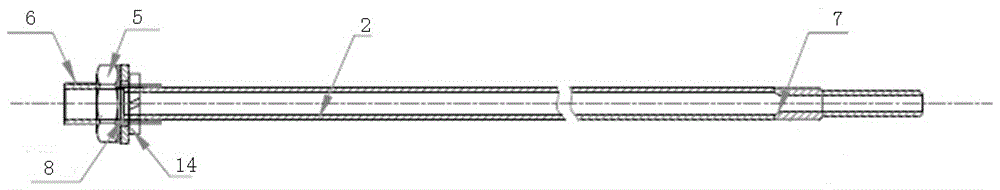

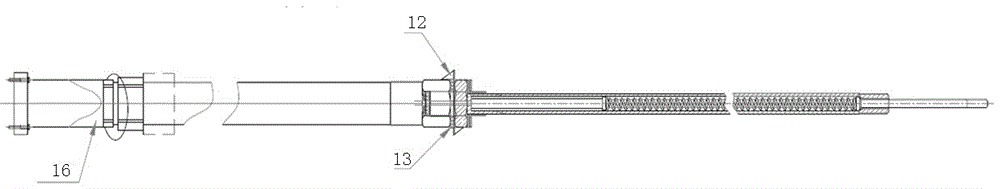

[0019] A separate elastic temperature sensor provided by the present invention, such as figure 1 with figure 2 As shown, it includes a temperature sensor probe 1 and an installation structure, and the installation structure includes a hollow protection tube 2 , a rear limit tube 3 and a telescopic spring 4 . Adopt PT100 type long probe temperature sensor.

[0020] Such as figure 2 As shown, the hollow protective tube 2 is made of a stainless steel pipe with a wall thickness greater than 1.5 mm and has better strength. Its tail is provided with an outer hexagonal head tightening seat 5 for installation, and the outer hexagonal head tightening seat is provided at the matching part of the mounting hole. Anti-vibration washers and rubber pads14. The outer side of the outer hexagon head tightening seat 5 is provided with a tightening nut mounting position 6 with an external pipe thread, and the external pipe thread is welded into one body with the hollow protective tube. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com