Mechanical device for multi-angle milling force loading of high-speed spindle unit

A high-speed spindle and mechanical device technology, applied in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inaccurate measurement of loading force, and achieve the effect of solving inaccurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

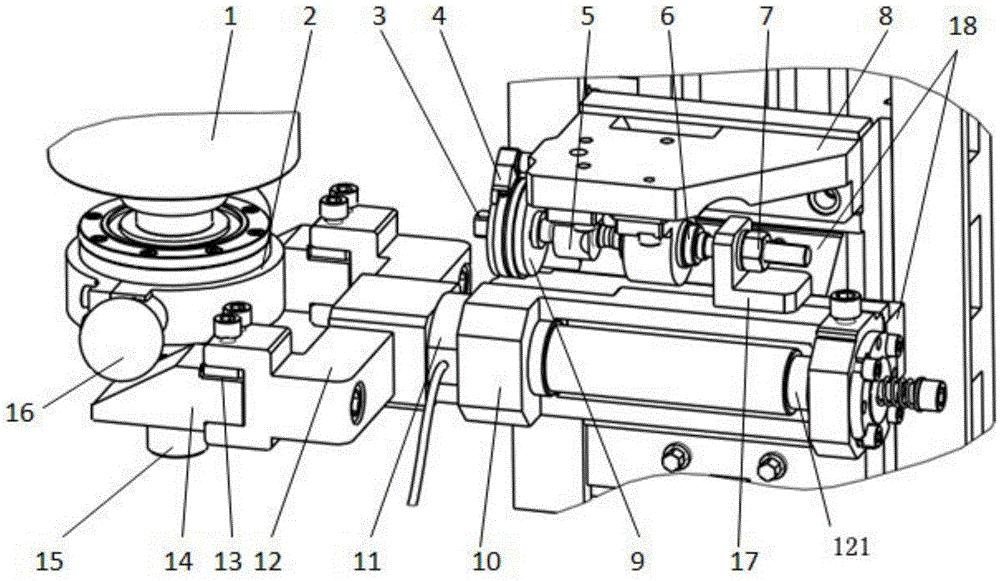

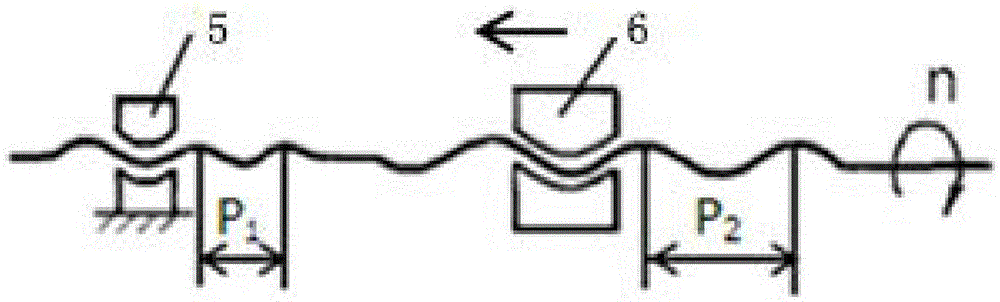

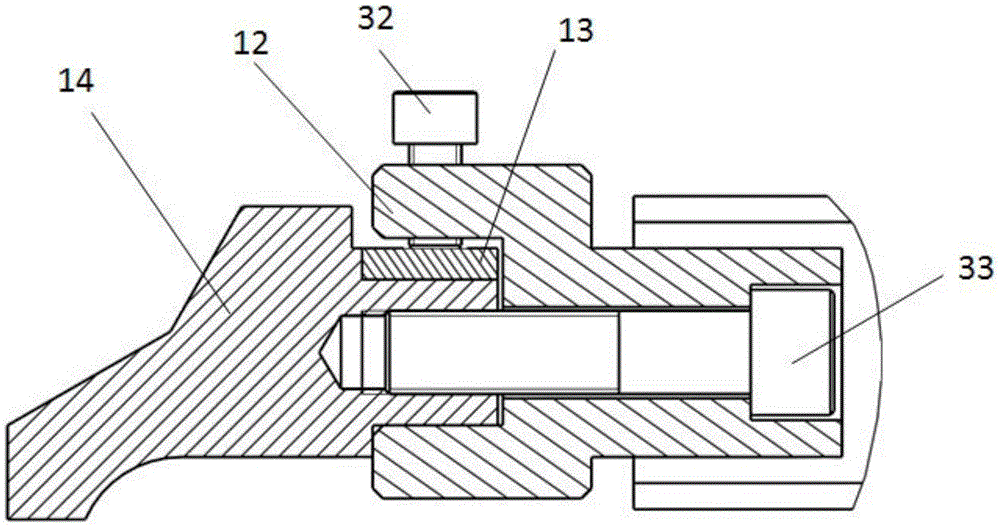

[0030] like Figure 1-5 As shown, the mechanical device for multi-angle milling force loading of the high-speed spindle unit includes the cutter shaft 15 connected with the spindle unit 1, the bearing seat 2 arranged on the cutter shaft 15, and the afterburner fixed on both sides of the bearing seat 2 Ball 16, force transmission mechanism and force loading mechanism. like figure 1As shown, the spindle unit 1 is fixed on the test bench, one end of the spindle unit 1 is connected with a cutter shaft 15, the cutter shaft 15 is provided with a bearing seat 2, and the two ends of the bearing seat 2 are fixed with an afterburner ball 16; The transmission mechanism includes a booster base 10 arranged on the linear guide rail-slider 18 and having a coaxial hole, a U-shaped frame 12 arranged at the head end of the booster base 10 and a booster slope 14 arranged at the head end of the U-shaped frame 12, The mandrel 121 at the tail end of the U-shaped frame 12 cooperates with the coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com