A welding defect extraction method and a welding defect detection method

A technology for welding defects and extraction methods, which is applied in image data processing, instrumentation, computing, etc., can solve the problems of PCNN's difficulty in distinguishing small noise edges and failing to optimally express image orientation information, and achieve the effect of fine contours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

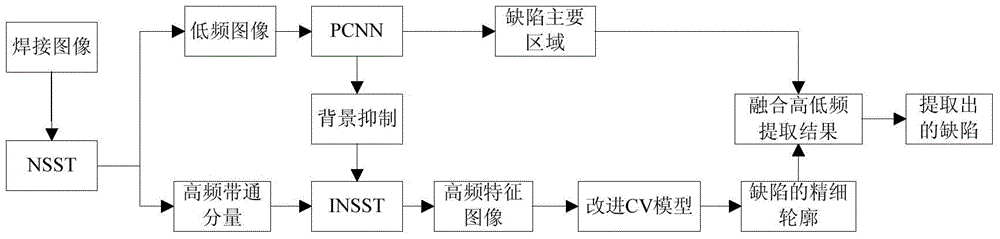

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

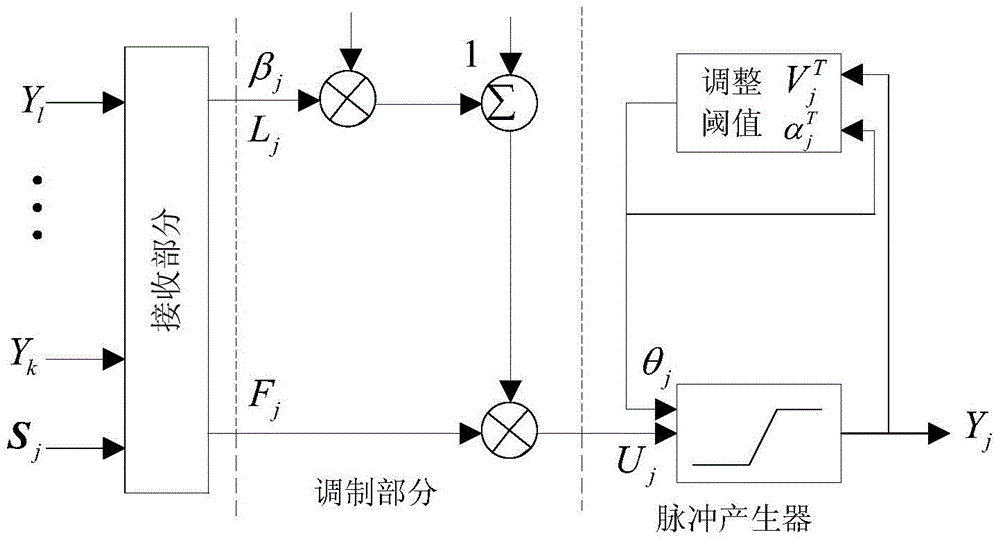

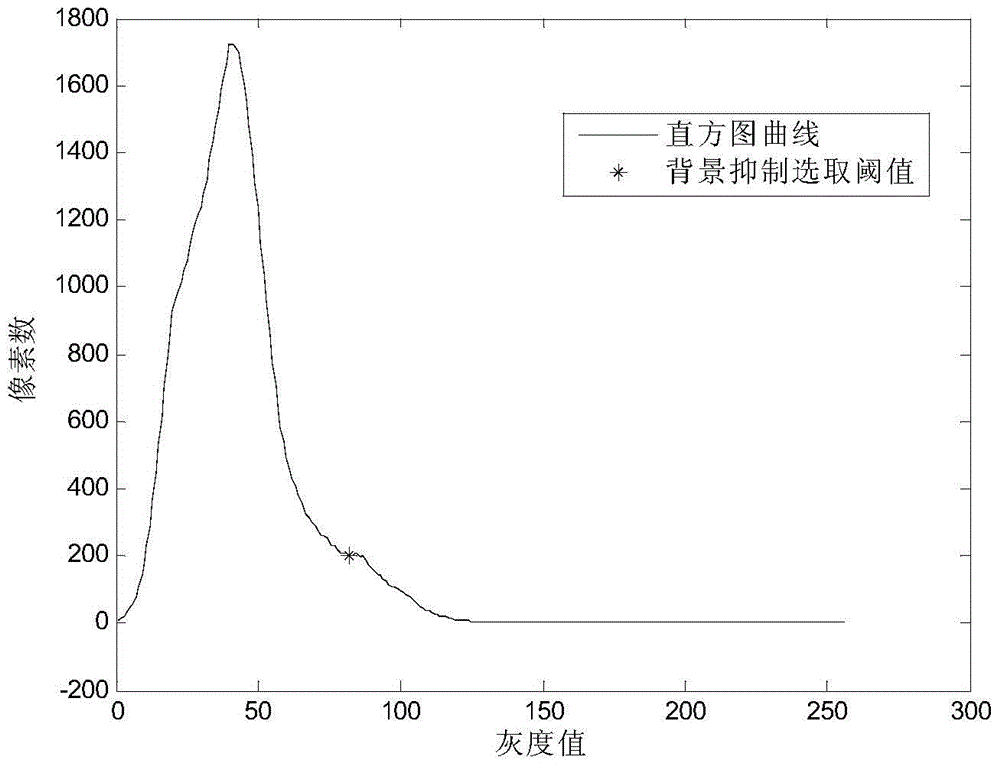

[0027] Aiming at the deficiencies of the prior art, the present invention adopts Non-SubsampledShearlet Transform (NSST) instead of NSCT, overcomes the pseudo-Gibbs effect produced by Shearlet, and more effectively captures detailed information of defects; utilizes PCNN to extract low-frequency components The main area of the defect; use the improved CV model added with the movement factor to extract the defects in the high-frequency component, avoid the loss of details, and improve the approximation effect of the edge. Using the welding defect extraction method proposed by the invention will make the defect and contour detection effect more obvious, thereby providing a more reasonable and accurate reference for further processing the defect.

[0028] In order to enable the public to better understand the technical solution of the present invention, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com