Air supply apparatus for plasma processing cavity, and de-clamping method

A technology of gas supply device and processing chamber, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as difficult substrates, chamber pollution, substrate damage, etc., achieve simple structure, avoid position deviation moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

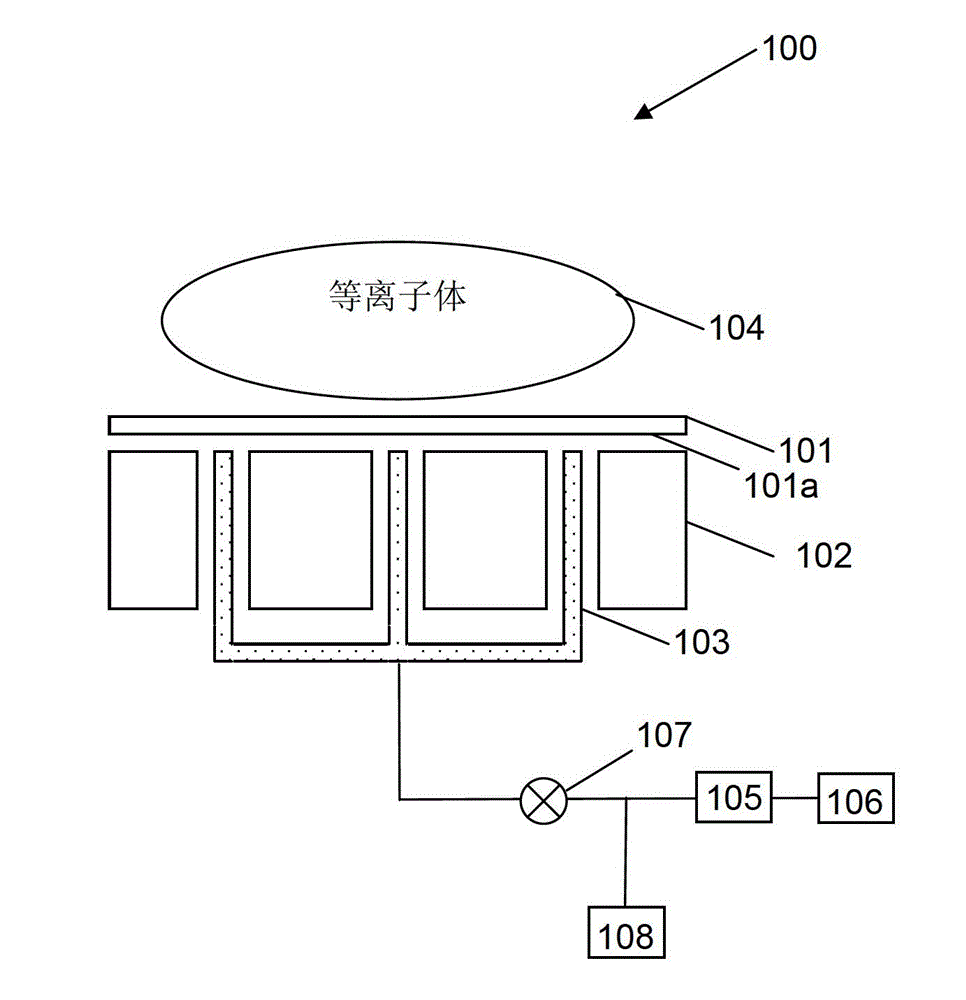

[0033] figure 1 is a schematic structural diagram of a gas supply system for a plasma processing chamber in the prior art. Such as figure 1 As shown, a process gas is introduced into the plasma chamber 100, and the process gas is excited to generate plasma due to the introduction of radio frequency energy, so as to perform related processes on the substrate 101 placed on the electrostatic chuck 102, such as etching and deposition Wait. The gas supply device provided in the prior art includes several gas channels 103, and the gas channels 103 are further connected in series with a control device 105 and a gas supply device 106 in series. Wherein, the gas supply device 106 is used for continuously supplying the first gas. A valve 107 is also provided upstream of the control device 105 .

[0034] A brief description of prior art de-clamping mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com