Chive phoenix roll and preparation method thereof

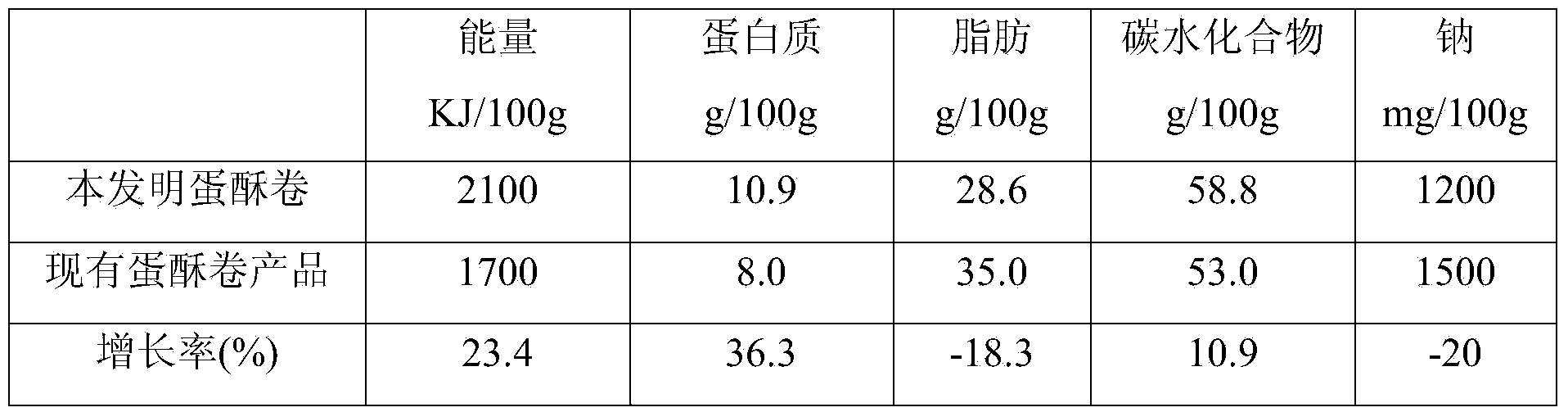

A chive and phoenix technology, applied in the preparation of the chive phoenix roll, in the field of chive phoenix roll, can solve the problems of incomplete nutrients, high unit cost, easy to break and break, etc., and achieve rich nutrition, quality improvement, matching reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Scallion Phoenix Roll, made of the following components by weight: 19 parts of water, 24 parts of white sugar powder, 0.3 parts of refined salt, 0.5 parts of shallot slices, 2 parts of milk powder, 0.2 parts of shallot essence, 24 parts of eggs, β - 0.12 parts of carotene and 30 parts of wheat flour.

[0027] Its preparation method comprises the following steps:

[0028] 1.1 Prepare egg roll paste

[0029] 1) Do a good job of preparation before seasoning, clean equipment, containers and utensils; and do a good job of disinfection.

[0030] 2) Weigh the raw materials correctly according to the formula requirements.

[0031] 3) Put water, white sugar powder, and refined salt into the mixing tank, control the temperature at 38°C, start stirring for 4.5 minutes, and turn off the machine after dissolving.

[0032] 4) Add shallot slices, milk powder, shallot essence, eggs, and β-carotene into the mixing tank. After stirring for 2.5 minutes, observe the uniformity of the st...

Embodiment 2

[0042] Chive phoenix rolls, made of the following components by weight: 18 parts of water, 23 parts of white sugar powder, 0.2 parts of refined salt, 0.4 parts of shallot slices, 2.2 parts of milk powder, 0.1 parts of shallot essence, 25 parts of eggs, β - 0.10 parts of carotene and 1 part of wheat flour.

[0043] Its preparation method comprises the following steps:

[0044] 1.1 Prepare egg roll paste

[0045] 1) Do a good job of preparation before seasoning, clean equipment, containers and utensils; and do a good job of disinfection.

[0046] 2) Weigh the raw materials correctly according to the formula requirements.

[0047] 3) Put water, white sugar powder, and refined salt into the mixing tank, control the temperature at 35°C, turn on the machine and stir for 5 minutes, and turn off the machine after dissolving.

[0048] 4) Add shallot slices, milk powder, shallot essence, eggs, and β-carotene into the mixing tank. After stirring for 3 minutes, observe the uniformity o...

Embodiment 3

[0058] Scallion Phoenix Roll, made of the following components by weight: 20 parts of water, 25 parts of white sugar powder, 0.4 parts of refined salt, 0.6 parts of shallot slices, 1.8 parts of milk powder, 0.3 parts of shallot essence, 23 parts of eggs, β - 0.12 parts of carotene and 29 parts of wheat flour.

[0059] Its preparation method comprises the following steps:

[0060] 1.1 Prepare egg roll paste

[0061] 1) Do a good job of preparation before seasoning, clean equipment, containers and utensils; and do a good job of disinfection.

[0062] 2) Weigh the raw materials correctly according to the formula requirements.

[0063] 3) Put water, white sugar powder, and refined salt into the mixing tank, control the temperature at 40°C, turn on the machine and stir for 4 minutes, and turn off the machine after dissolving.

[0064] 4) Add shallot slices, milk powder, shallot essence, eggs, and β-carotene into the mixing tank. After stirring for 2.5 minutes, observe the uniformi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com