A catalyst recovery and loading method

A catalyst and compound technology, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve problems such as poor dispersion, low catalyst loading rate, and complicated two process steps, so as to improve loading efficiency , Increase the effect of the active site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

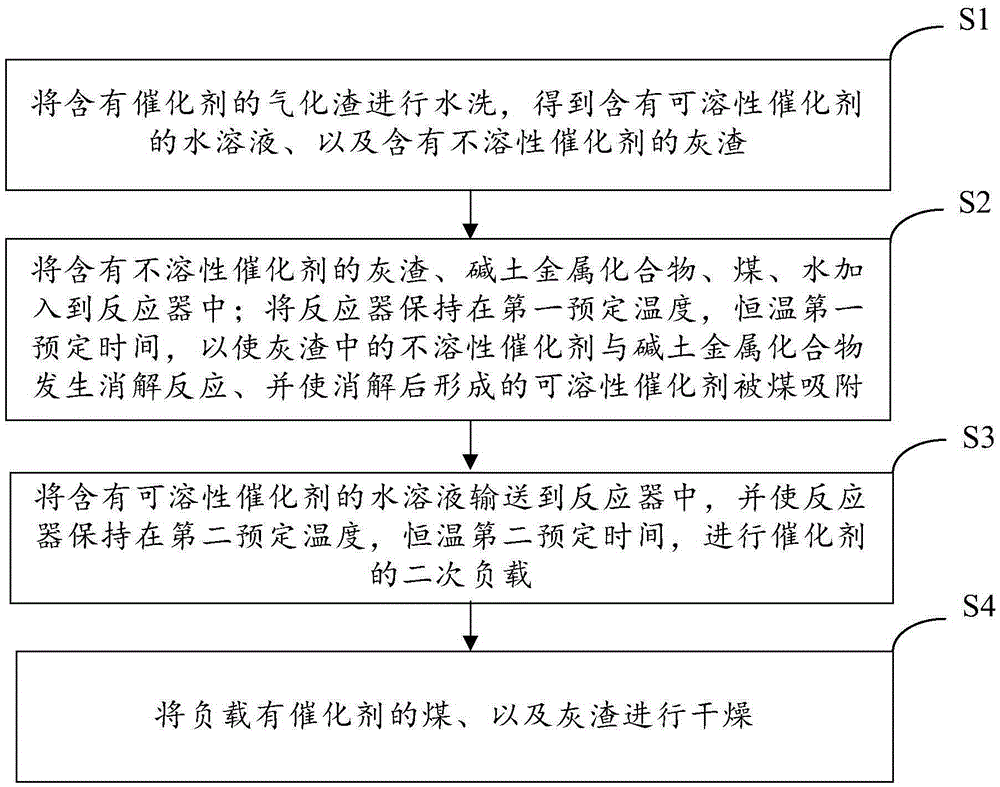

Method used

Image

Examples

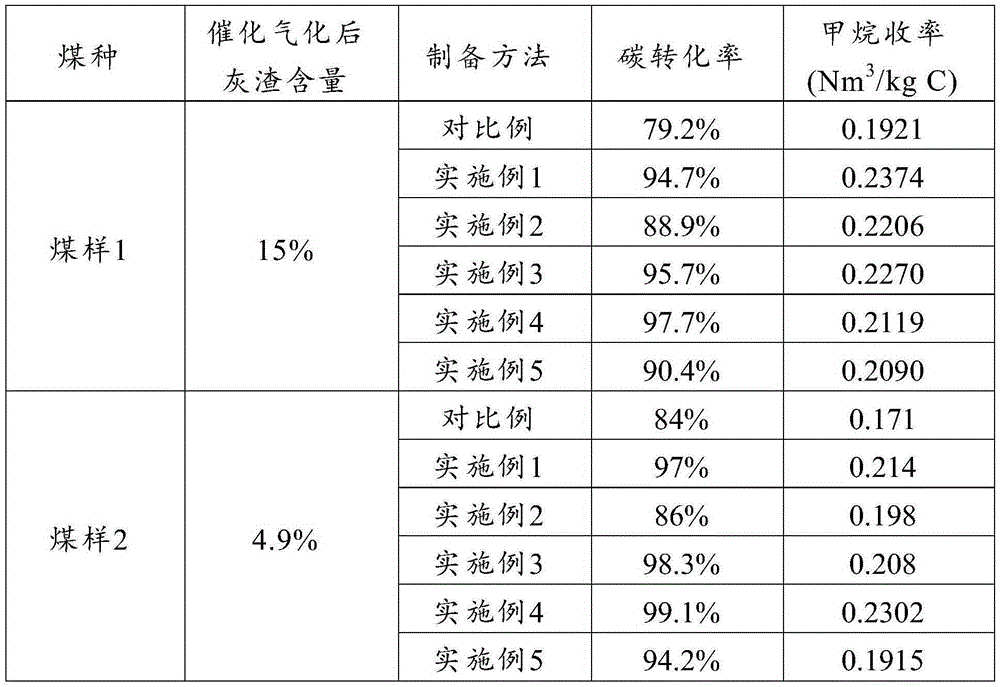

Embodiment 1

[0060] Soluble catalyst recovery: 30g ash (after analysis, K in the ash + The content is equivalent to 10gK 2 CO 3 Medium K + content) was first washed with 100ml water, and the obtained product contained soluble K + The water washing solution of the catalyst is used for standby.

[0061] Insoluble catalyst recovery and catalyst loading: Put 100g of coal and washed ash into 150g of water together with the prepared 10g of Ca(OH) 2 100ml of the suspension was poured into a reaction kettle, heated to 300°C, stirred, and kept at a constant temperature for 2h.

[0062] Hydrothermal impregnation loading of soluble catalysts: will contain soluble K + Put 90-100ml of water washing solution of the catalyst into the above-mentioned reaction kettle, raise the temperature to 180°C, impregnate and load the catalyst under hydrothermal conditions, keep the temperature for 0.5h, and put the coal into an oven to dry at 120°C for 12h after impregnation. Sampling for later use.

Embodiment 2

[0064] Soluble catalyst recovery: 30g ash (after analysis, K in the ash + The content is equivalent to 10gK 2 CO 3 Middle K + content) was first washed with 150ml water, and the obtained product contained soluble K + The water washing solution of the catalyst is used for standby.

[0065] Insoluble catalyst recovery and catalyst loading: Put 100g of coal and washed ash into 150g of water together with the prepared 10g of Ca(OH) 2 100ml of the suspension was poured into a reaction kettle, heated to 400°C, stirred, and kept at a constant temperature for 1h.

[0066] Soluble catalyst impregnated load at room temperature: will contain soluble K + Put 90-100ml of water washing solution of the catalyst into the above reaction kettle, stir at room temperature 20°C for 4h, then put the coal into an oven and dry at 120°C for 12h. Sampling for later use.

Embodiment 3

[0068] Soluble catalyst recovery: 30g ash (after analysis, K in the ash + The content is equivalent to 10gK 2 CO 3 Medium K + content) was first washed with 100ml water, and the obtained product contained soluble K + The water washing solution of the catalyst is used for standby.

[0069] Insoluble catalyst recovery and catalyst loading: Put 100g of coal and washed ash into 150g of water together with the prepared 8g of Ca(OH) 2 and 3.6g CaSO 4 Pour 100ml of the suspension into a reaction kettle, heat to 200°C, stir, and keep the temperature constant for 4h.

[0070] Soluble catalyst impregnated load at room temperature: will contain soluble K + Put 90-100ml of water washing solution of the catalyst into the above reaction kettle, stir at room temperature 25°C for 1h, then put the coal into an oven and dry at 120°C for 12h. Sampling for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com