Automatic lifting device for carrying paper cocooning frame after cocoon removal

An automatic lifting and grid cluster technology, which is applied in transportation and packaging, loading/unloading, animal husbandry, etc., can solve the problems of soiling, germ contamination, and grid clusters are easy to be damaged by collision, so as to avoid collision damage and low price , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

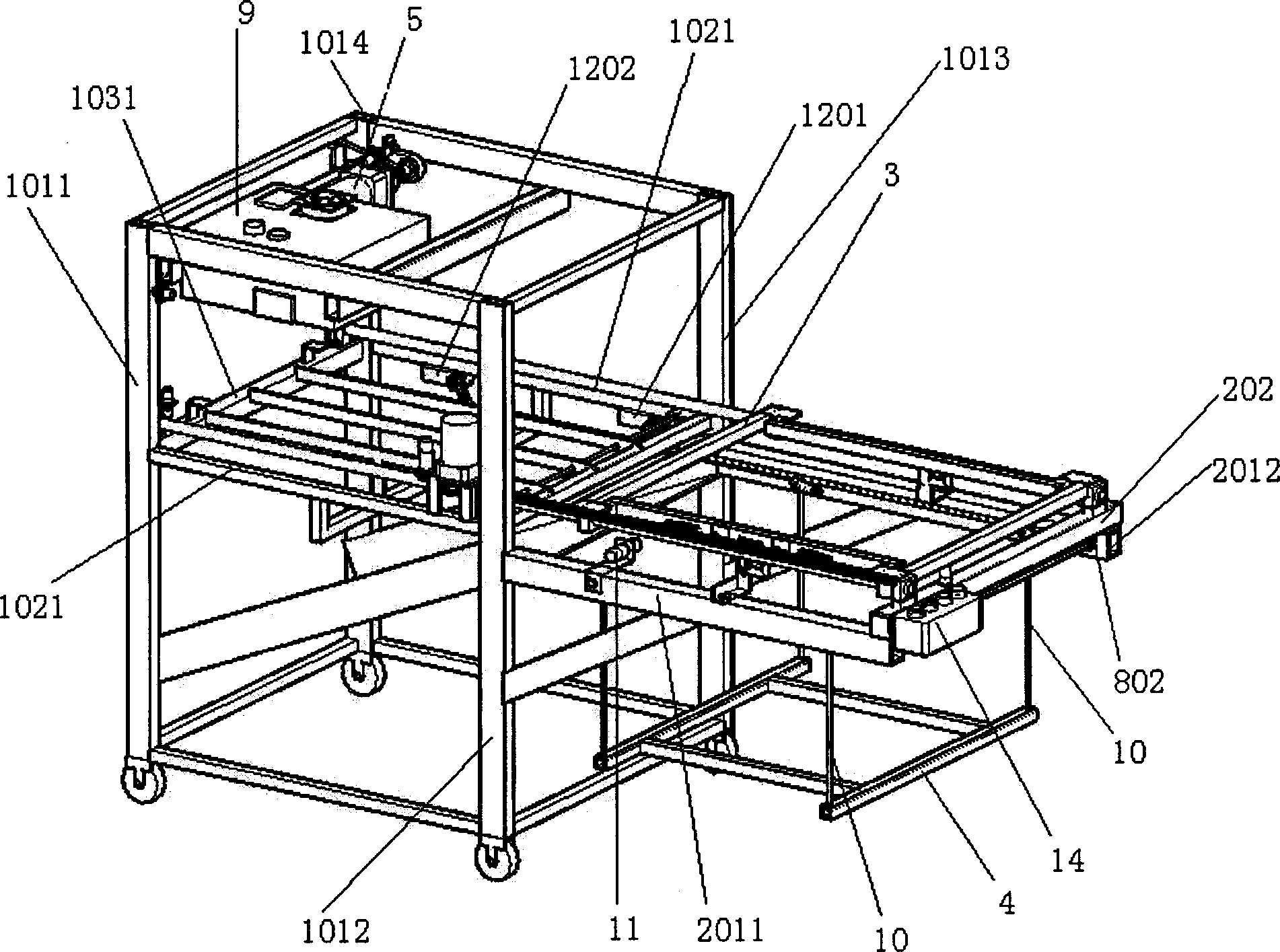

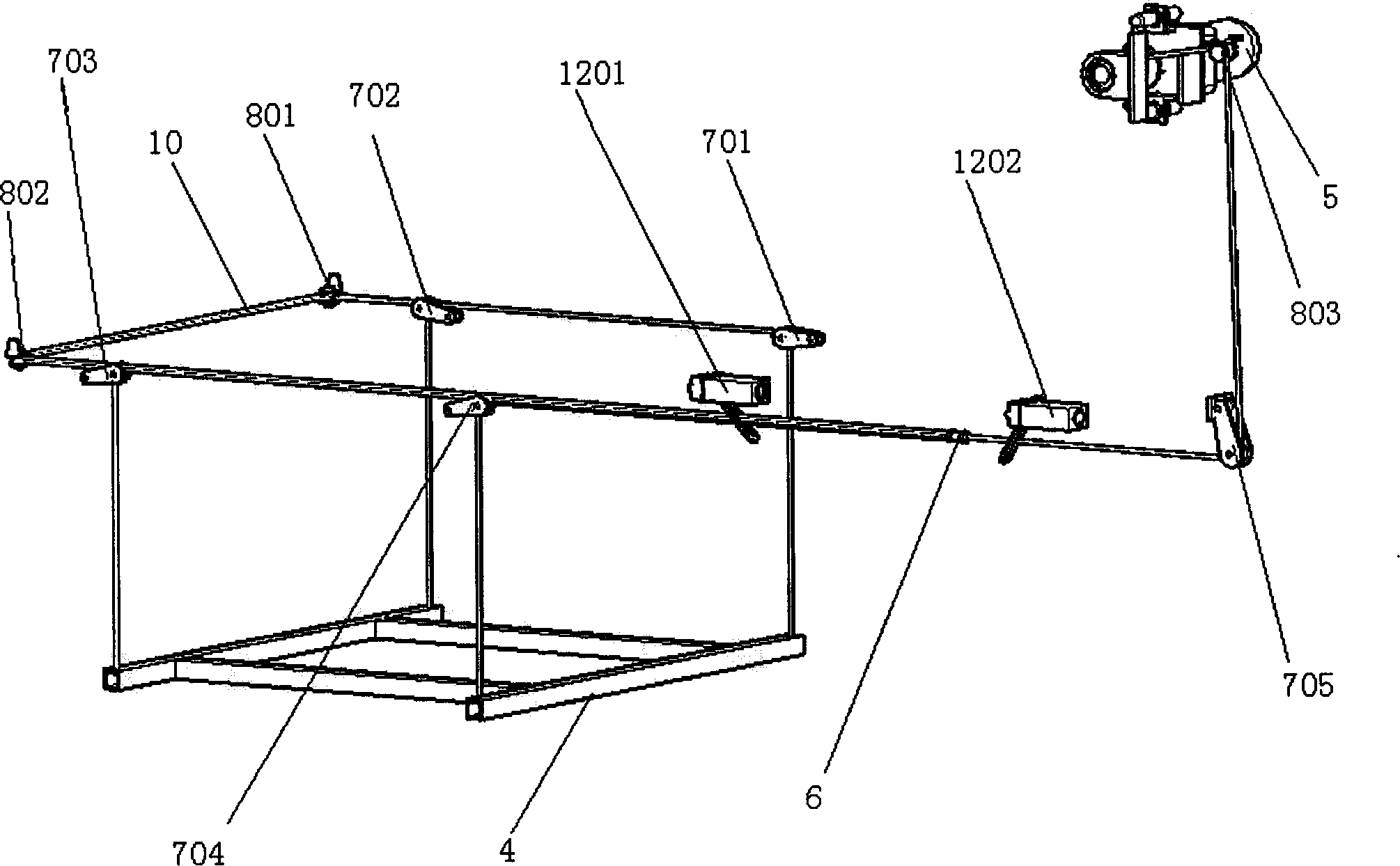

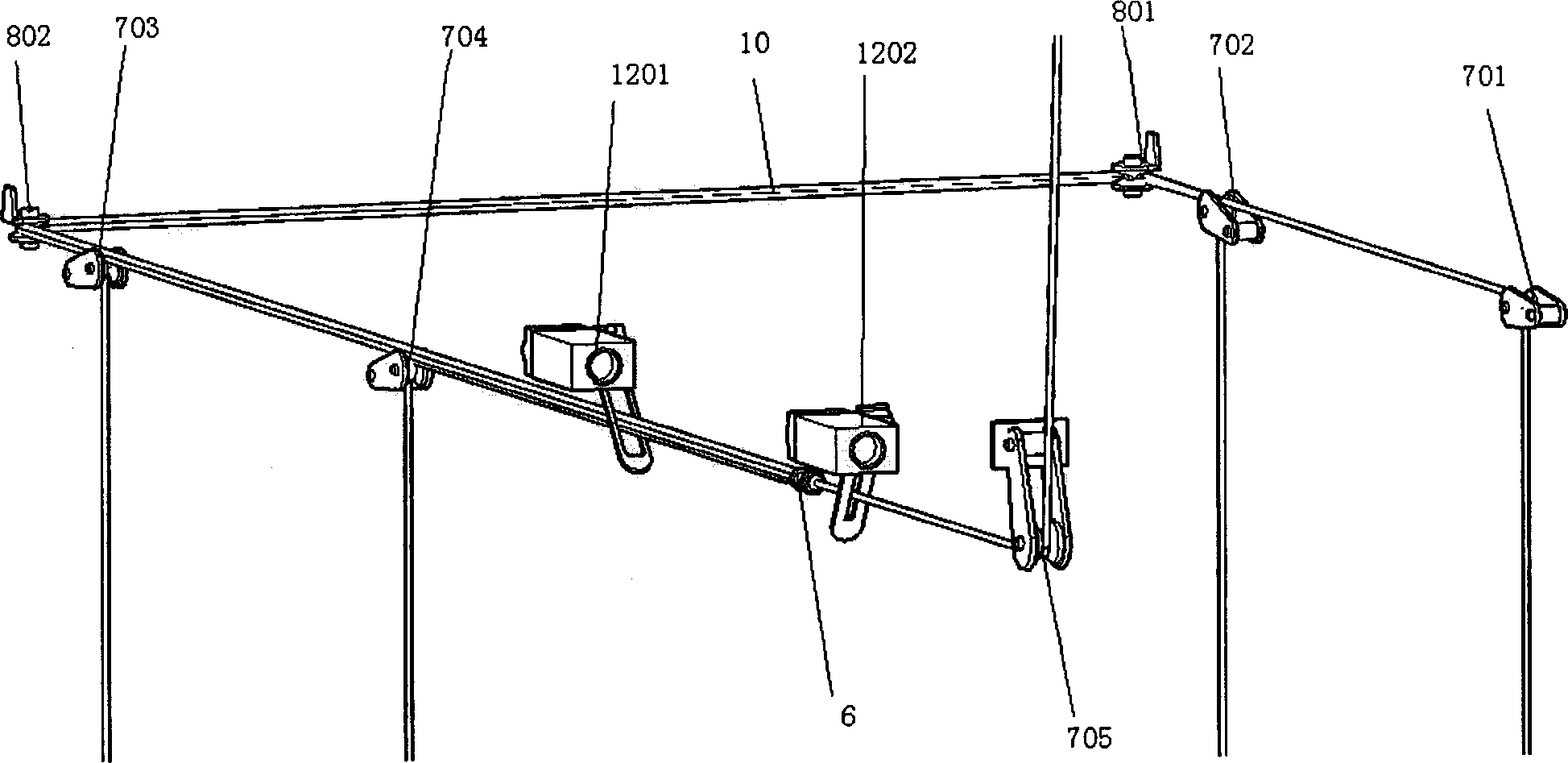

[0011] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. In the embodiment, the metal rope 10 is made of iron material, the attachment frame 4 is made of iron material or plastic, and the length and width of the lifting frame 4 are respectively 70 cm and 50 cm. After purchasing other components, follow the above instructions. and attached drawings.

[0012] Press the operation control box 14, the power supply module 901 in the circuit control device 9 provides the working voltage for the microprocessor control unit and the DC motor 5, the whole circuit and the microcircuit are energized, the DC motor 5 is started, the metal rope 10 is tightened through five One movable pulley and three corner pulleys pull up the lifting frame 4. When the lifting frame reaches the highest height, the contacts of the travel switch 1202 are pulled apart, and the DC motor 5 stops rotating; When the switch 11 is directly in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com