A kind of environment-friendly polyurethane water blocking reinforcement material and preparation method thereof

A reinforcement material, polyurethane technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of increasing costs, hidden safety hazards, and high equipment requirements, and achieve good water-encapsulation, less human harm, and repeated water blocking effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

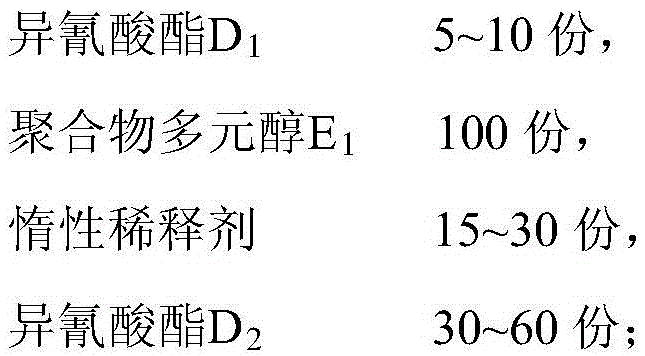

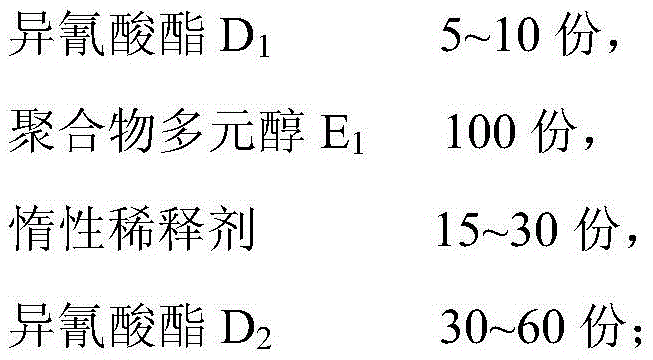

[0030] (1) Add polymer polyol E to the reactor equipped with agitator 1 (Functionality is 3, hydroxyl value 27mgKOH / g) 100 parts, dehydrated under reduced pressure at 120°C for 2 hours, cooled to 30°C, then added 5 parts of toluene diisocyanate, reacted at 60°C for 4 hours, cooled to 25°C, Add 40 parts of polymethylene polyphenyl polyisocyanate and 30 parts of dimethyl methylphosphonate, stir evenly, and it is component A.

[0031] (2) Polymer polyol E 2 (Functionality is 3, hydroxyl value 450mgKOH / g) 30 parts, 3 parts of dibutyltin dilaurate and 2 parts of polyether siloxane are mixed and stirred evenly to form component B.

[0032] (3) When using, mix component A and component B evenly at a weight ratio of 6:1 to obtain an environmentally friendly polyurethane water blocking reinforcement material.

[0033] The technical indicators of the products obtained in the above examples are as follows:

[0034] Component A Viscosity

Embodiment 2

[0036] (1) Add polymer polyol E to the reactor equipped with agitator 1 (Functionality is 3, hydroxyl value 27mgKOH / g) 100 parts, dehydrated under reduced pressure at 120°C for 2 hours, cooled to 30°C, then added 6 parts of diphenylmethane diisocyanate, reacted at 80°C for 2.5 hours, cooled to At 25°C, add 45 parts of polymethylene polyphenyl polyisocyanate and 30 parts of propylene glycol carbonate, stir evenly, and form A component.

[0037] (2) Polymer polyol E 2 (Functionality is 3, hydroxyl value 450mgKOH / g) 35 parts, 2 parts of butadiene dilaurate and 1.5 parts of polyether siloxane are mixed and stirred evenly to form component B.

[0038] (3) When using, mix component A and component B uniformly at a weight ratio of 8:1 to obtain an environmentally friendly polyurethane water blocking reinforcement material.

[0039] The technical indicators of the products obtained in the above examples are as follows:

[0040] Component A Viscosity

Embodiment 3

[0042] (1) Add polymer polyol E to the reactor equipped with agitator 1 (Functionality is 3, hydroxyl value 27mgKOH / g) 100 parts, dehydrated under reduced pressure at 110°C for 2 hours, cooled to 30°C, then added 6 parts of toluene diisocyanate, reacted at 70°C for 3 hours, cooled to 25°C, Add 35 parts of polymethylene polyphenyl polyisocyanate and 25 parts of propylene glycol carbonate, stir evenly, it is A component.

[0043] (2) Polymer polyol E 2 (Functionality is 3, hydroxyl value 450mgKOH / g) 28 parts, 0.5 part of triethanolamine and 1 part of polyether siloxane are mixed and stirred evenly to form component B.

[0044] (3) When using, mix component A and component B evenly at a weight ratio of 6:1 to obtain an environmentally friendly polyurethane water blocking reinforcement material.

[0045] The technical indicators of the products obtained in the above examples are as follows:

[0046] Component A Viscosity

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com