A kind of environment-friendly water-based polyurethane grouting water blocking material and preparation method thereof

A water-based polyurethane and environment-friendly technology, applied in the field of high-performance water-based polyurethane water blocking materials, can solve the problems of safety production threat, unhealthy construction personnel, serious environmental pollution, etc., and achieve good irrigation performance and good secondary water blocking ability , good permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

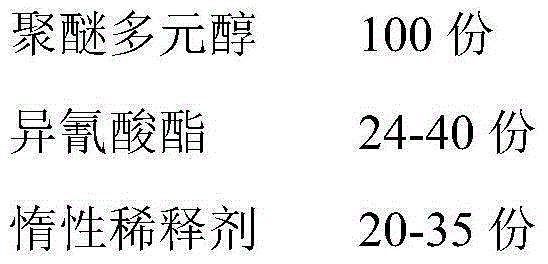

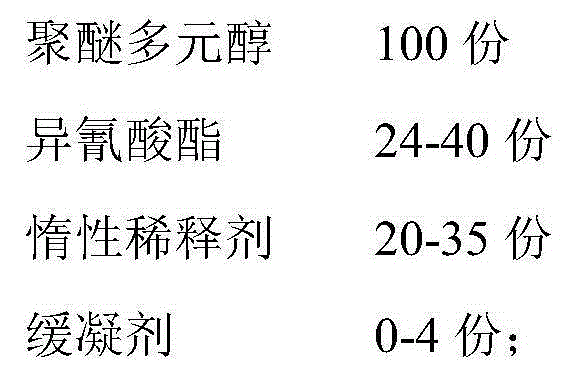

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 90g of highly hydrophilic polyether polyol (functionality: 3, EO / PO=85 / 15, molecular weight: 6500) and 10g of PEG2000 to a closed reaction kettle equipped with a reflux condensing device and a stirring device, at 120°C , The vacuum degree is -0.085MPa, dehydration for 2.5h.

[0035] (2) When the temperature drops to 30°C, add MDI-5035g, pass N 2 protection, stirred evenly, then raised the temperature to 80°C, reacted for 2 hours, added 32g of inert diluent, and stirred evenly to obtain a polyurethane prepolymer solution, namely component A.

[0036] (3) No catalyst and crosslinking agent are added, and only water is used as component B of the water blocking material.

[0037] (4) Mix component A and component B at a volume ratio of 1:1 to obtain the final gel.

[0038] The technical indicators of the products obtained in the above examples are as follows:

[0039] performance

[0040] Gel time (s)

Embodiment 2

[0042] (1) Add 100g of highly hydrophilic polyether polyol (functionality 3, EO / PO=85 / 15, molecular weight 6500) into a closed reaction kettle equipped with a reflux condensing device and a stirring device. Dehydration for 2 hours at -0.085MPa.

[0043] (2) When the temperature drops to 30°C, add TDI6g, pass N 2 Protect, stir evenly, heat up to 60°C, react for 3h, add MDI-5026g, heat up to 75°C, continue to react for 2h, add inert diluent 30g, stir well to obtain polyurethane prepolymer, component A.

[0044] (3) Component B was obtained by dissolving 1.6 g of triethanolamine in 160 g of water.

[0045] (4) Mix component A and component B at a volume ratio of 1:1 to obtain the final gel.

[0046] The technical indicators of the products obtained in the above examples are as follows:

[0047] performance

Embodiment 3

[0049] (1) Add 90g of highly hydrophilic polyether polyol (functionality 3, EO / PO=85 / 15, molecular weight 6500) and 10g of polyether N220 into a closed reaction kettle equipped with a reflux condensing device and a stirring device, Dehydrate for 2 hours at 120°C and a vacuum of -0.085MPa.

[0050] (2) When the temperature drops to 30°C, add MDI-5040g, pass N 2 protection, stir evenly, heat up to 80°C, react for 2 hours, add 35g of inert diluent, stir evenly to obtain polyurethane prepolymer, ie component A.

[0051] (3) Dissolve 1 g of triethanolamine and 0.8 g of triethylenediamine in 180 g of water to obtain component B.

[0052](4) Mix component A and component B at a volume ratio of 1:1 to obtain the final gel.

[0053] The technical indicators of the products obtained in the above examples are as follows:

[0054] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com