De-foaming agent and preparation method thereof

A technology of defoaming agent and manufacturing method, which is applied in the field of defoaming agent and its preparation, can solve the problems of defoaming performance decline, shrinkage cavity, phase separation, etc., and achieve the effect of reducing surface tension and good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

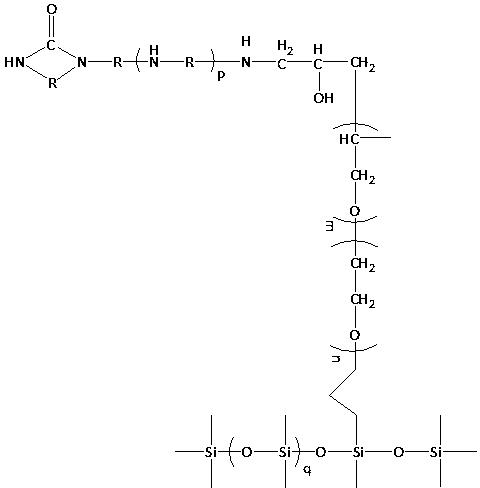

Method used

Image

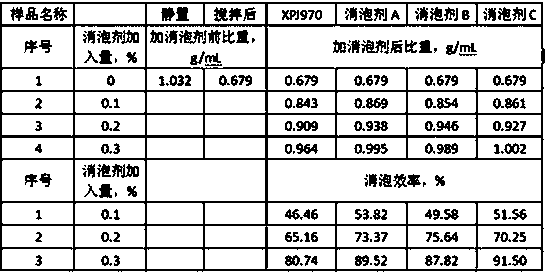

Examples

Embodiment 1

[0023] A kind of defoamer manufacture method of the present invention is as follows:

[0024] a) Add 1030g of diethylenetriamine and 600g of urea into a 2L autoclave, heat to 150°C and keep for 24 hours. Cool down to below 50°C to obtain cyclic urea compound P1;

[0025] b) Put 290g of 2-propen-1-ol and 1g of catalyst sodium methoxide into a 5L autoclave, heat up to 120°C, and remove water by vacuuming until the weight ratio of water is less than 0.3%; then heat up to 150°C, After adding 580g of propylene oxide, heat it at 150°C for 3 hours; then cool it down to 120°C, add 1540g of ethylene oxide, heat it at 120°C for 2 hours, then cool it to below 60°C; add 462g of epichlorohydrin, and heat up to Heat preservation and aging at 100°C for 4 hours, lower the temperature to below 50°C, add 265g of solid sodium carbonate, stir for 20 minutes, remove the solid by filtration, and obtain allyl alcohol polyether P2;

[0026] c) Add 1000 g of cyclic urea compound P1 into 3300 g of al...

Embodiment 2

[0030] A kind of defoamer manufacture method of the present invention is as follows:

[0031] a) Add 890g of triethylenetetramine and 360g of urea into a 2L autoclave, heat to 180°C and keep for 40 hours. Cool down to below 50°C. Cyclic urea compound Q1 is obtained.

[0032]b) Put 290g of 2-propen-1-ol and 2.7g of catalyst potassium hydroxide into a 5L autoclave, heat up to 120°C, and remove water by vacuuming until the weight ratio of water is less than 0.3%; keep at 120°C , add 2200g of ethylene oxide, heat at 120°C for 3 hours and cool down to below 60°C; add 463g of epichlorohydrin, heat up to 100°C for 4 hours, cool to below 50°C, add 265g of solid sodium carbonate , stirred for 20 minutes, and filtered to remove the solid to obtain allyl alcohol polyether Q2.

[0033] c) Add 618g of cyclic urea compound Q1 into 1660g of allyl alcohol polyether Q2, raise the temperature to 110°C, and react for 3 hours. After the reaction is completed, the water is removed by vacuum or...

Embodiment 3

[0037] A kind of defoamer manufacture method of the present invention is as follows:

[0038] a) Add 1100g of tetraethylenepentamine and 350g of urea into a 1L autoclave, heat to 230°C and keep for 48 hours. Cool down to below 50°C. Obtain cyclic urea compound R1;

[0039] b) Put 58g of 2-propen-1-ol and 0.22g of sodium methoxide into a 2L autoclave, heat up to 120°C, and remove water by vacuuming until the weight ratio of water is less than 0.3%; then heat up to 150°C After adding 464g of propylene oxide, it was incubated at 150°C for 4 hours; then the temperature was lowered to 120°C, 132g of ethylene oxide was added, and it was incubated at 120°C for 1 hour, then cooled to below 60°C; 92.52g of epichlorohydrin was added, Raise the temperature to 100°C and heat-preserve for 4 hours, cool down to below 50°C, add solid sodium carbonate, stir to make the system pH=7-9, and then filter to obtain allyl alcohol polyether R2;

[0040] c) Add 250 g of cyclic urea compound R1 into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com