Hydrophilic double-component grouting plugging material

A leakage plugging material and two-component technology, applied in the field of high-performance hydrophilic polyurethane/water glass two-component grouting plugging material and its preparation, can solve the problem of insufficient curing time, poor stability of consolidated body, and adjustable The problem of small range, etc., to achieve the effect of efficient water blocking and water blocking performance, fast gel speed, and improving water blocking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 95g of highly hydrophilic polyether polyol (functionality 3, molecular weight 6000, EO / PO=75:25), 5g of polyvinyl alcohol 2000, and 10g of DBP into the reaction kettle together, at a vacuum degree of -0.08MPa , vacuum dehydration at 115°C for 2 hours; after cooling down to 60°C, add 20g of toluene diisocyanate into the reaction kettle under nitrogen atmosphere, and react for 3h; Finally, add 60 g of propylene carbonate and 0.02 g of benzenesulfonyl chloride into the reaction kettle under a nitrogen atmosphere, stir for 20 minutes, and discharge to obtain Component A.

[0039] (2) Dissolve 0.5g of stannous octoate and 5g of diethylenetriamine in 100g of water glass solution (the mass fraction of sodium silicate is 30%, and the modulus of sodium silicate is 3.5) to obtain component B.

[0040] (3) Mix component A and component B at a volume ratio of 1:5 to prepare a hydrophilic polyurethane / water glass composite hydrogel sample.

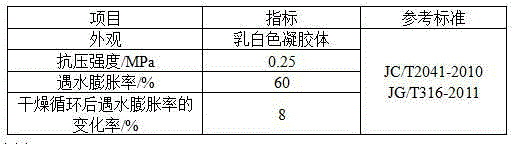

[0041] Table 1 Main technical ...

Embodiment 2

[0046] (1) Weigh 80g of highly hydrophilic polyether polyol (functionality 3, molecular weight 8200, EO / PO=80:20), 20g of PTMEG1000, 50g of DOP and put them into the reactor together. Vacuum dehydration at ℃ for 2 hours; after cooling down to 60℃, add 9g of toluene diisocyanate into the reaction kettle under nitrogen atmosphere, and react for 3h; keep at 60℃, add 31g of liquefied diphenylmethane diisocyanate into the reaction kettle under nitrogen atmosphere Isocyanate, continue to react for 1h; add 0.3g dibutyltin dilaurate to the reaction kettle to continue the reaction for 1h, after cooling down to 50°C, add 20g of mixed dibasic acid ester and 0.05g of anhydrous phosphoric acid to the reaction kettle under nitrogen atmosphere, After stirring for 10-30 minutes, the material is discharged to obtain component A.

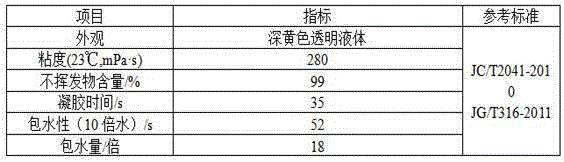

[0047] (2) Dissolve 2g of triethylamine and 2g of triethanolamine in 100g of water glass solution (the mass fraction of sodium silicate is 30%, and the modulus of so...

Embodiment 3

[0054] (1) Weigh 90g of highly hydrophilic polyether polyol (functionality 3, molecular weight 10000, EO / PO=95:5), 10g of polyvinyl alcohol 200, and 30g of DOP into the reaction kettle together. MPa, vacuum dehydration at 115°C for 2h; after cooling down to 60°C, add 27.6g of toluene diisocyanate to the reactor under nitrogen atmosphere, and react for 3h; keep at 60°C, add 33.4g more Phenyl polymethylene polyisocyanate, continue to react for 1h; add 0.23g 2,2-bismorpholinyl diethyl ether to the reaction kettle and continue to react for 1h, after cooling down to 50°C, put it into the reaction kettle under nitrogen atmosphere Add 40g of 1,2-propanediol carbonate and 0.03g of tartaric acid, stir for 10-30min, and discharge to obtain component A.

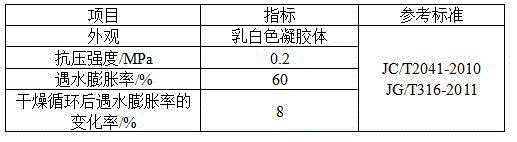

[0055] (2) Dissolve 1g of N,N-dimethylbenzylamine and 4g of m-phenylenediamine in 100g of water glass solution (the mass fraction of sodium silicate is 60%, and the modulus of sodium silicate is 1.5) to obtain the composition Point B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com