Heating distillation device of steamer pot of white spirits

A technology for heating distillation and retort, which is applied in the field of electric heating retort multi-layer distillation devices, can solve problems such as being difficult to meet and meet teaching requirements, and achieves the effects of good teaching effect, reasonable design and realistic distillation links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

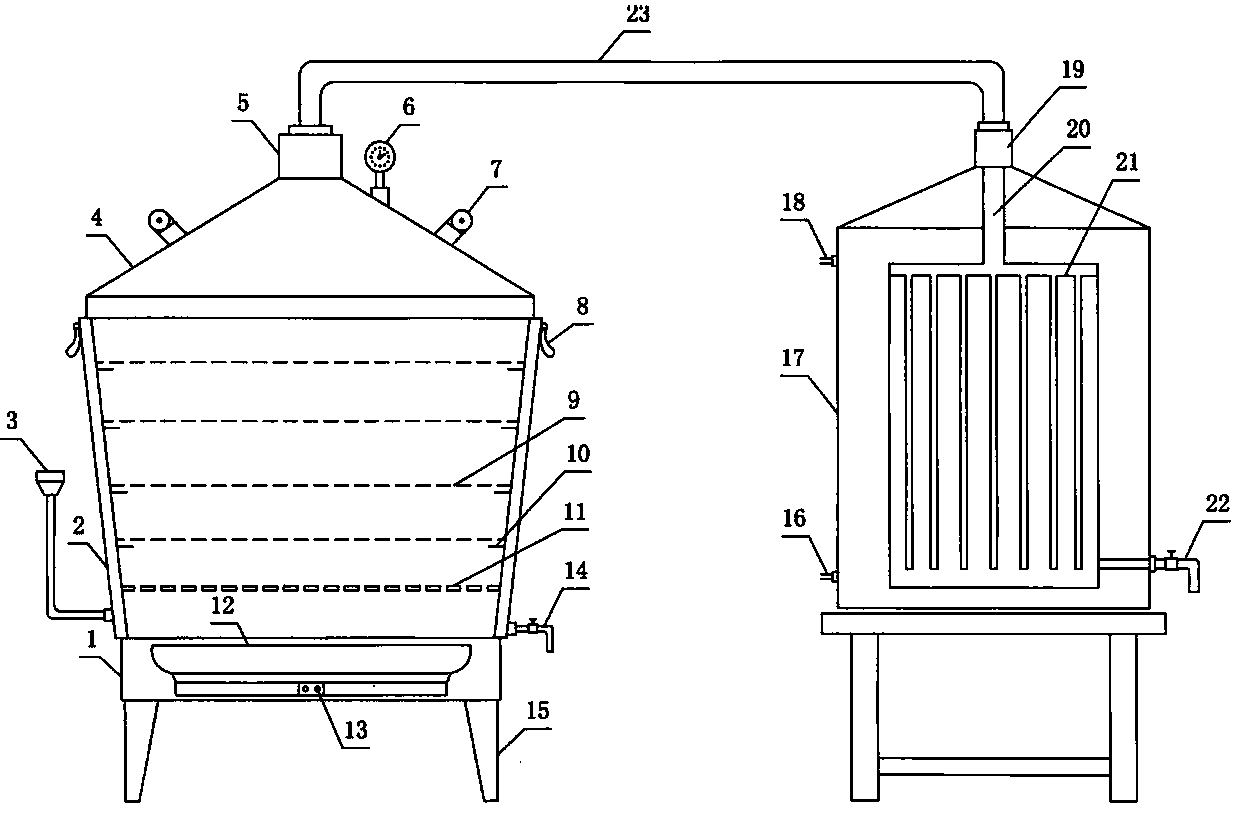

[0010] figure 1 The bottom end of the retort pot 2 shown in the figure is provided with a bottom pot 1, and the pot body of the bottom pot is provided with an electric heating plate 12, and the front end of the electric heating plate is provided with a power socket 13, and the bottom end of the pot body is provided with a porous retort grate 11. The pot wall at the upper end of the steamer grate is provided with a multi-layer support plate 10, the support plate is provided with a movable grate 9, the upper end of the steamer pot is provided with a steamer cover 4, the left side of the steamer pot is provided with a water injection port 3, and the right side of the steamer pot is provided with a water injection port 3. A drain valve 14 is provided, a bracket 15 is provided at the bottom of the bottom pot, a handle 8 is provided at the upper end of the retort pot, a handle 7 is provided at the upper end of the retort cover, and an air outlet connection sealing port 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com