High temperature sticking resistant composition for vanadium and titanium-containing molten iron desulphurization, high temperature sticking resistant agent, and application of

A technology of hot metal desulfurization and composition, which is applied in the field of high-temperature anti-sticking agent and high-temperature anti-sticking composition for vanadium-titanium hot metal desulfurization. The effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

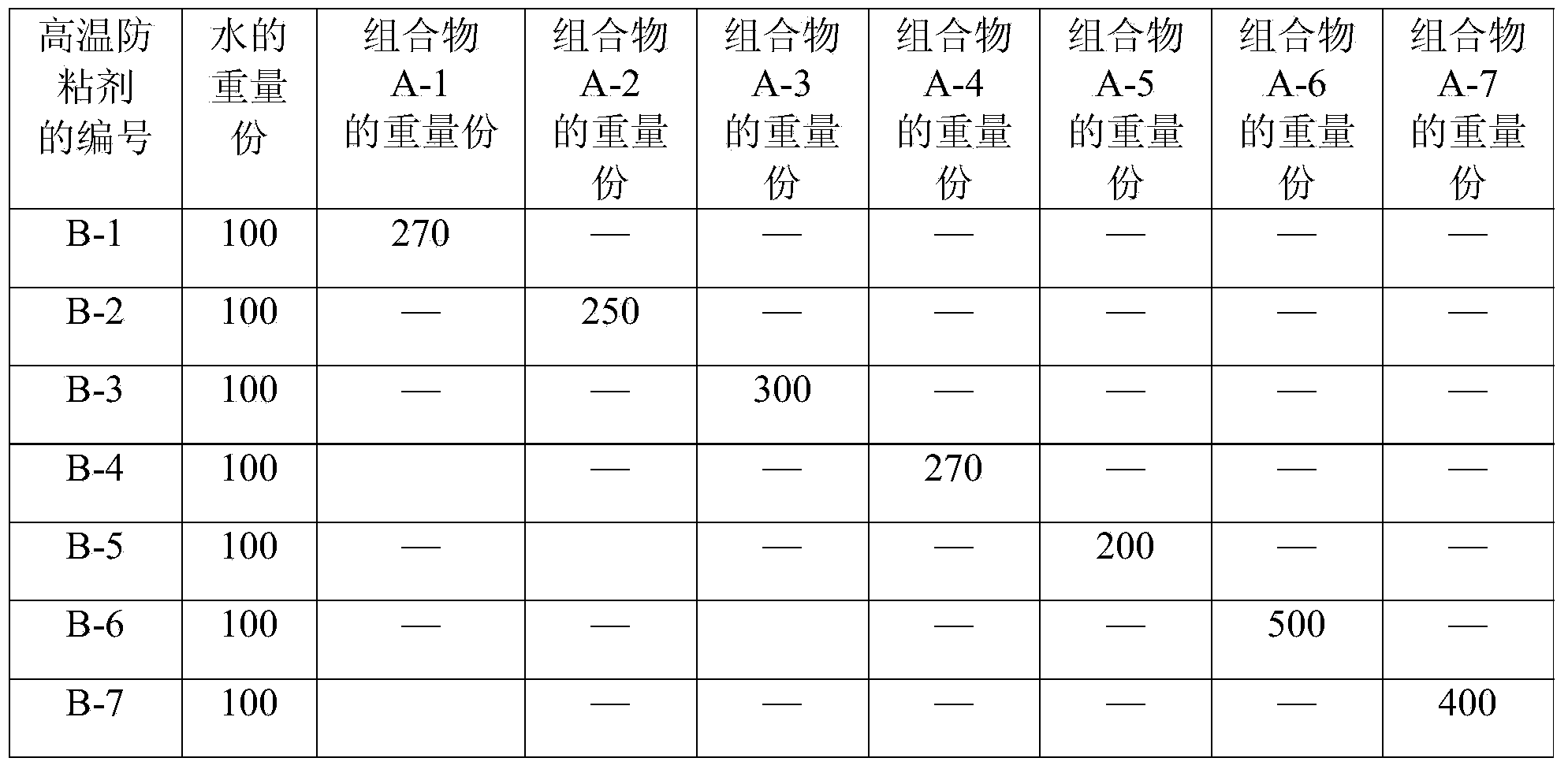

Examples

preparation example 1

[0030] This preparation example is used to prepare the high temperature release composition of the present invention.

[0031] Get 300kg of corundum slag, the by-product after hydrometallurgy vanadium slag, the main components and content of which are respectively: 62 parts by weight of Al 2 o 3 , 9 parts by weight of CaO, 21 parts by weight of MgO, 8 parts by weight of V 2 o 3 and unavoidable impurities, the corundum slag was ground into uniform fine particles, and the measured proportion of the particle size was less than 4mm was 98.9% by weight. The resulting composition was numbered A-1.

preparation example 2

[0033] This preparation example is used to prepare the high temperature release composition of the present invention.

[0034] Take 65 parts by weight of Al 2 o 3, 8 parts by weight of CaO, 20 parts by weight of MgO and 7 parts by weight of V 2 o 3 Grind into fine powder and mix evenly, and the ratio of particle size less than 4mm is 98.9% by weight. The resulting composition was designated A-2.

preparation example 3

[0036] This preparation example is used to prepare the high temperature release composition of the present invention.

[0037] Take 60 parts by weight of Al 2 o 3 , 10 parts by weight of CaO, 23 parts by weight of MgO and 7 parts by weight of V 2 o 3 Grind into fine powder and mix evenly, and the ratio of particle size less than 4mm is 98.9% by weight. The resulting composition was designated A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com