A method for installing steel beams in steel structure engineering

An installation method and steel structure technology, which are applied in building construction, building material processing, construction, etc., can solve the problems of reducing labor productivity, heavy weight, safety accidents, etc., so as to improve labor productivity, reduce production costs, and reduce safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

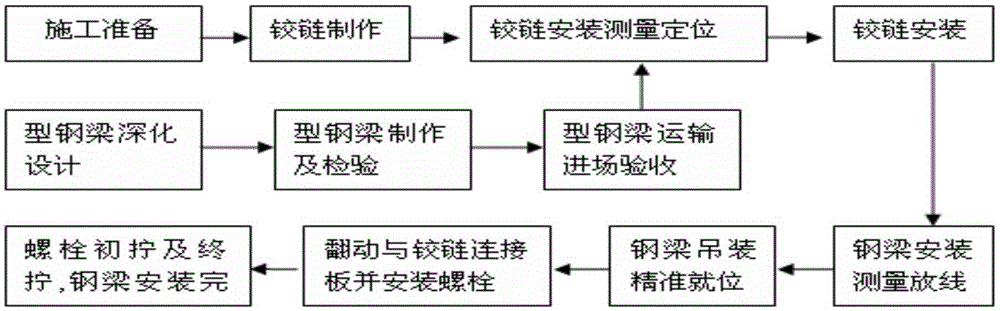

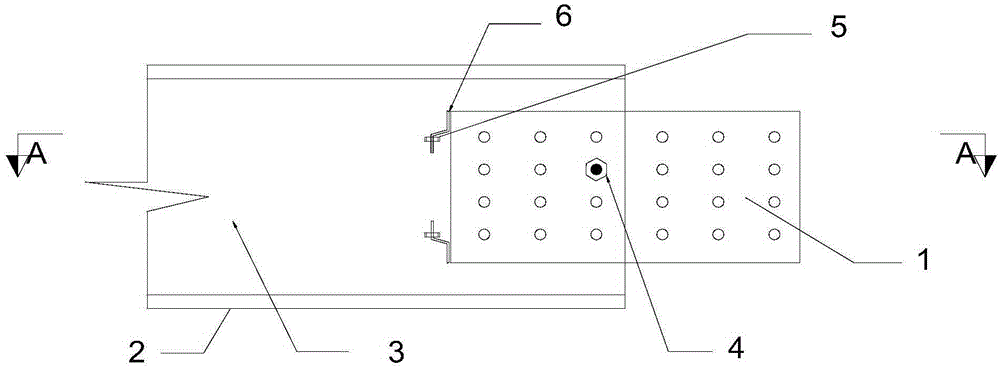

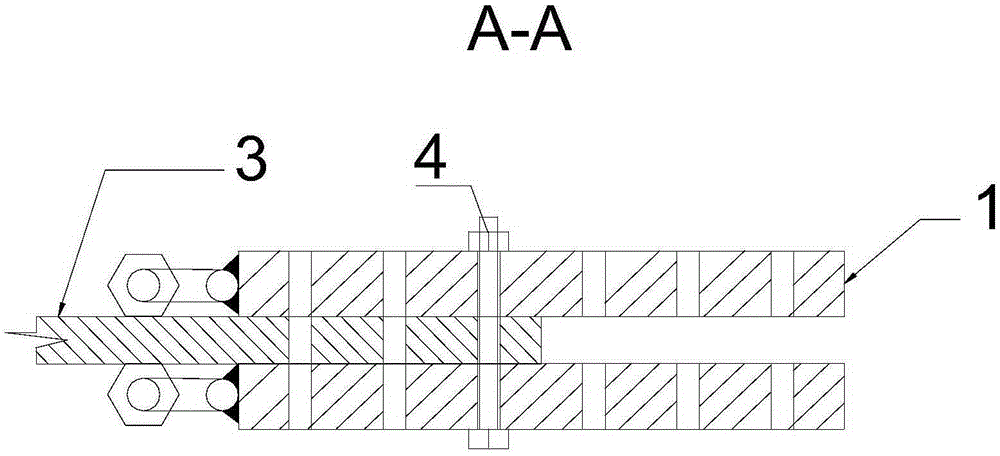

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] Take the steel structure construction of Building B3, a high-end hotel and office building in Changsha Poly International Plaza as an example.

[0023] Project Overview

[0024] Changsha Poly·International Plaza Building B3 is located at the northeast corner of the intersection of Nanhu Road and Xiangjiang Road in Changsha City. It is a super high-rise building integrating commerce, restaurants, hotels and office buildings. 213380㎡, the total height of the building is 249m; the main structure adopts a hybrid structure-reinforced concrete core tube-outrigger truss structure, the basement adopts stiffened reinforced concrete columns, and the ground adopts 24 steel tube concrete columns-steel truss structure, the steel structure is generally used The amount of steel is 19000t. There are at least 193 beams on a single floor, up to 218 beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com