Improved opposite impact silencer

An improved muffler technology, applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of weakening the effect of pressure offset, poor effect, and limited muffler effect, so as to improve the airflow buffering effect and muffle the noise Enhanced effect, fully hedged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

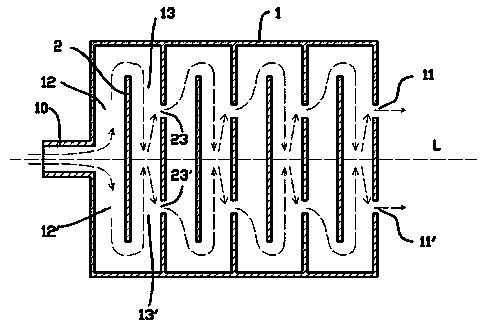

[0021] figure 1 Shown is the first embodiment of the muffler, wherein the muffler includes an air inlet 10, an exhaust port 11, 11'; the main part of the muffler is between the air inlet 10 and the air outlet 11, 11' , the main body part is surrounded by a flat cuboid metal cavity 1 .

[0022] Inside the metal cavity 1 , four splitting and hedging units connected end-to-end are separated by a partition plate 2 , and the internal channel structure of the splitting and hedging unit is also separated by the partition plate 2 .

[0023] Each of the splitting and countering units includes two splitting passages 12, 12' that symmetrically divide the intake air flow into two, and converging passages 13, 13 that merge the airflows in the two splitting passages 12, 12' facing each other. '; The channel walls of the two converging channels are respectively provided with air outlets 23, 23'; the air outlets 23, 23' are symmetrical about the confluence center of the air flow, that is, ab...

Embodiment 2

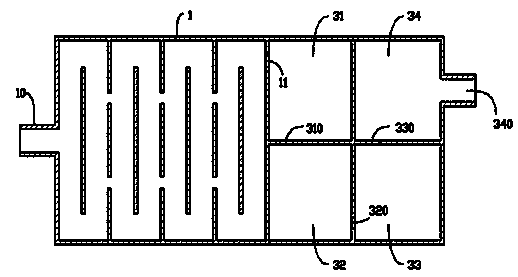

[0030] figure 2 Shown is the second embodiment of the muffler, which is different from the first embodiment in that: only one exhaust port 11 is provided on the last mentioned diversion and hedging unit, and a conventional muffler is connected through the exhaust port 11 body; the conventional muffling body includes four muffling chambers 31, 32, 33, 34, and each muffling chamber communicates with each other through mutually staggered airflow inlets and outlets 310, 320, 330; the air outlet of the last muffling chamber 34 340 is used as the exhaust port of the whole muffler; in order to further improve the muffler effect, muffler cotton can be arranged on the inner wall of each muffler cavity 31-34.

[0031] Due to the hedging and muffler in front of the conventional muffler, the exhaust noise of the engine has been weakened to a very weak level. In this case, the muffler cavity in the conventional muffler only needs a small volume to remove residual noise. Intersecting wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com