Method and apparatus for seamless state transfer between user interface devices in a mobile control room

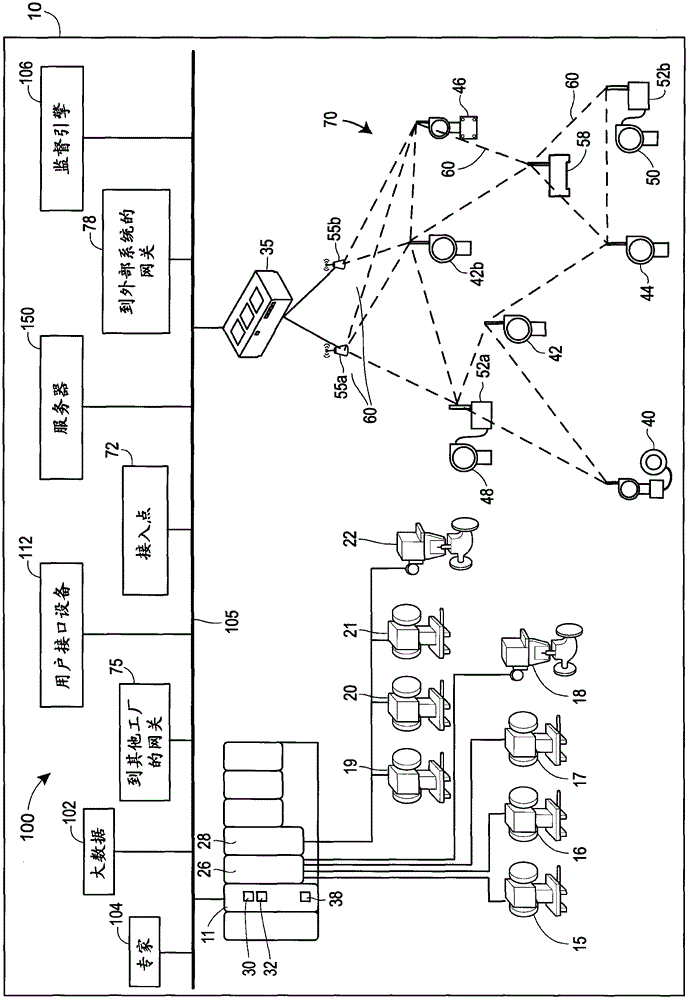

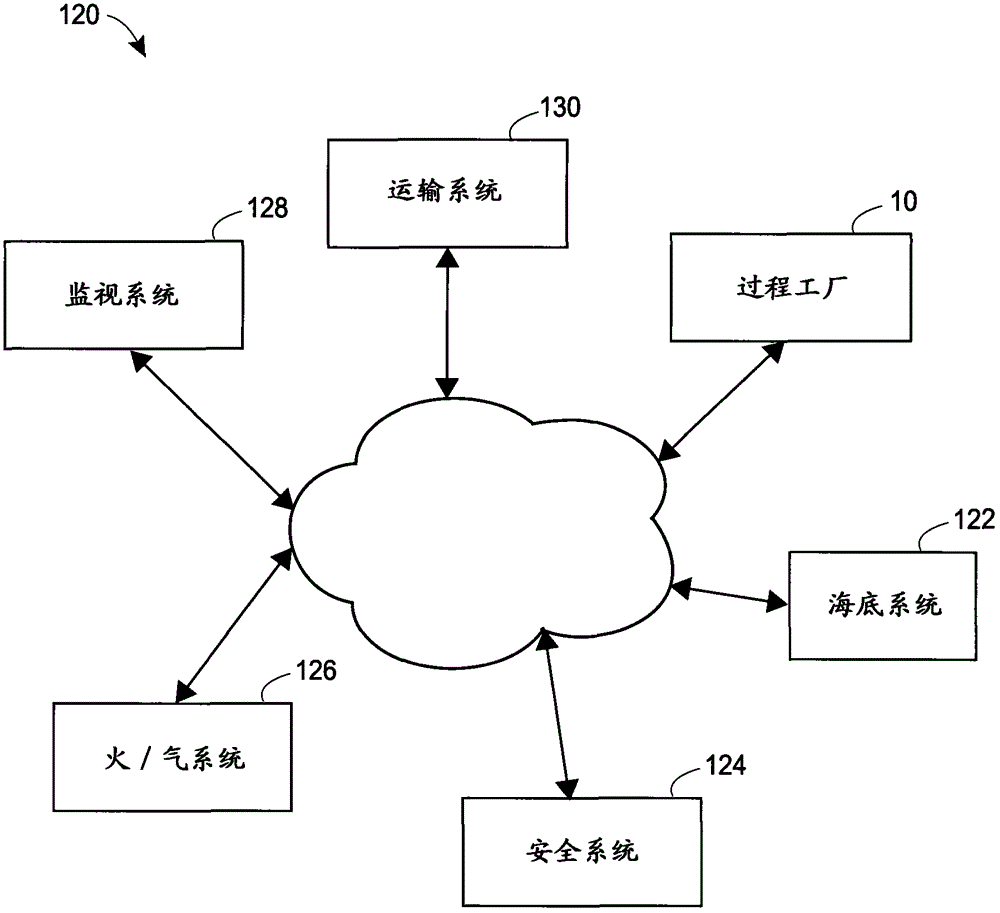

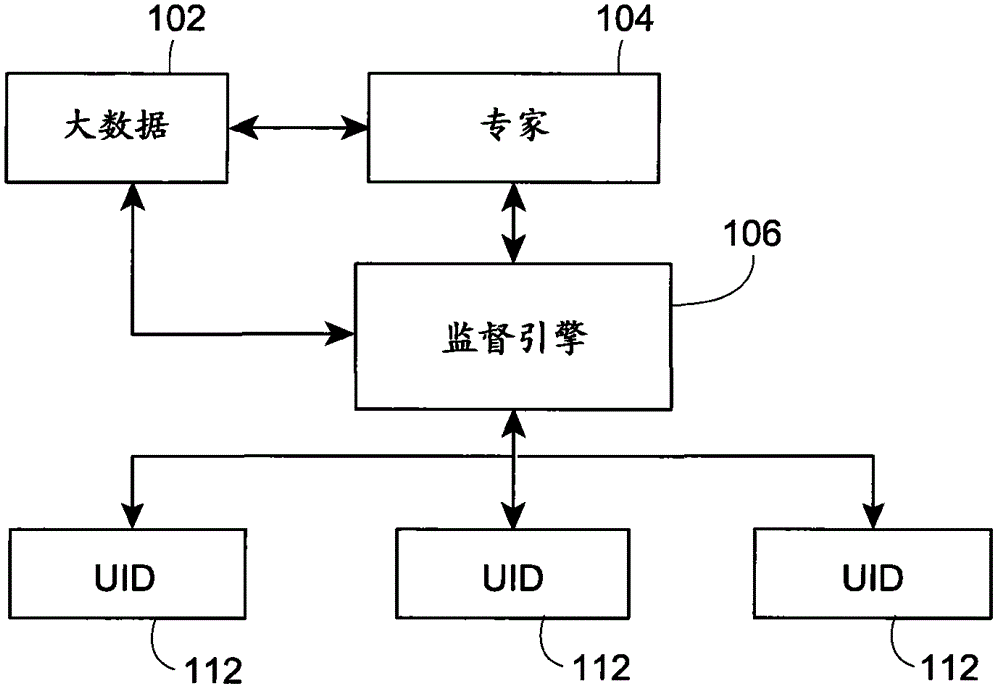

A user interface and mobile device technology, applied in the direction of program control in sequence/logic controller, general control system, program control, etc., can solve problems such as redundant, insufficient bandwidth or offset time stamp, data inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0077] A first user assigned to a particular area of the plant can monitor the assigned plant area via a fixed workstation in the control room. The first user monitors and controls the process via a browser or other application running on the workstation in communication with routines executing at the server. The first user may determine where to go to the process plant to, for example, inspect the plant. When the user leaves the control room, the user can pick up the touch-sensitive tablet device (ie, the second, mobile user interface device) and walk out of the control room to the factory. The tablet device, like a workstation, enables the first user to access routines at the server via a browser or application executing on the tablet device. The first user may have been authenticated on the tablet device, or the tablet device may be associated with the first user. The tablet device communicates with the server to establish a session unique to the first user. The server...

example 2

[0085] The first user still carrying the tablet device can start walking from the process plant to the control room of the process plant. The first user may pass the boiler. When the first user walks near the boiler, the tablet device establishes RFID communication with the boiler environment ID device. The tablet device can receive the unique identifier from the context ID device and send the unique identifier to the server. The server can identify the boiler based on the unique identifier. The server may access the environmental data to determine that the boiler has an associated work item, and compare the skill threshold associated with the work item to the skill level associated with the first user's profile. When it is determined that the first user is not eligible to work on the work item associated with the boiler, the server may alert the display of the tablet device in advance, instead of updating the display with information related to the work item.

[0086] The ...

example 3

[0088] The first user continues to walk through the factory, still holding the tablet in hand. A second user, located in the control room and now logged into the workstation (or a different workstation) previously occupied by the first user, can notice that the critical O2 gas measurement associated with the furnace is dropping. The second user creates a work item requesting assistance with the furnace body. When the first user passes the furnace on his way back to the control room, the tablet device can automatically establish communication with the furnace environment ID device so that the tablet device receives a unique identifier associated with the furnace. The tablet device can send the unique identifier to the server, which can return information associated with the unique identifier (eg, information about the furnace), including notification graphics that the furnace needs attention. The first user can see and select the notification graphic so that information relate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com