Automatic stereoscopic warehouse demonstration teaching aid box

A technology of three-dimensional warehouses and teaching aids, applied in the field of teaching aids, can solve the problems of unrealistic cognition of mechanical principles and operation methods, lack of teaching models, and difficult operating procedures for students, so as to achieve easy teaching, easy movement, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

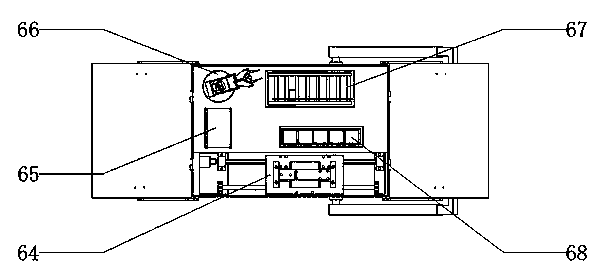

[0021] An automatic three-dimensional warehouse demonstration teaching aid box, comprising: a pallet shelf 68 and a double-column roadway stacker 64 are installed on the inner bottom plate of the box body 47, and a roller conveyor 67, a loading platform 65 and a manipulator are installed on the other side bottom plate 66.

[0022] Described box body 47, the bottom of box body 47 is equipped with wheel 46, and side wall is equipped with pull bar 52, and box body 47 is made up of each box surface and box body cover 49 by seamless page 51 connection, and limit position is also set on the box body. device 48, a control layer 50 is arranged inside the box body, and a lifting mechanism 71 is arranged inside the box body. The overall case is compact, light in weight and easy to carry.

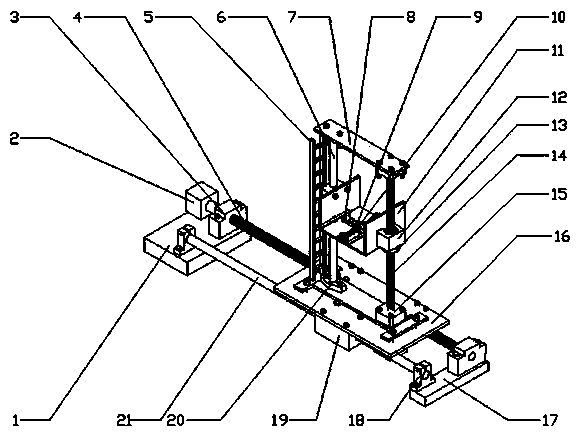

[0023] The described double-column roadway stacker 64 includes: a left base plate 1, a motor 2 and a left support base 3 are installed above the left base plate 1, and one end of the lead screw 4 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com