Short-circuited prevention power failure resetting type snap action thermostat

A sudden jump thermostat and power-off reset technology, which is applied to thermal switch components and other directions, can solve problems such as unreliable contact, short circuit, and reduce the stability of PTC heating elements, so as to achieve stable connection and eliminate potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail by the following examples.

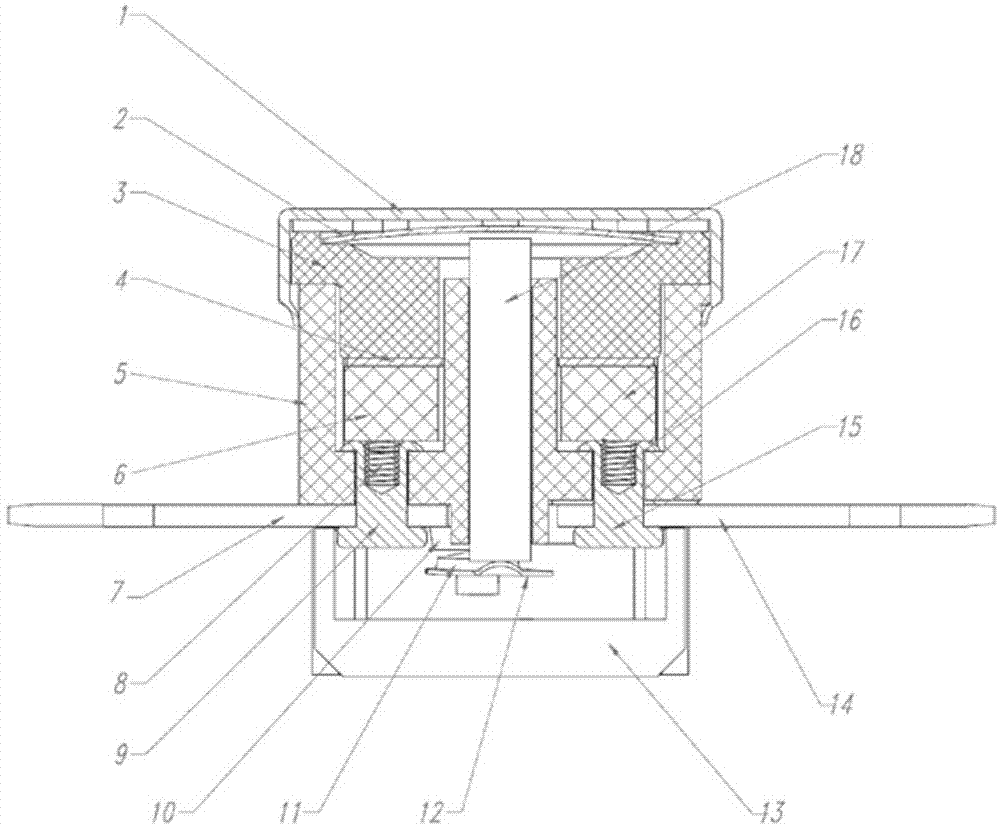

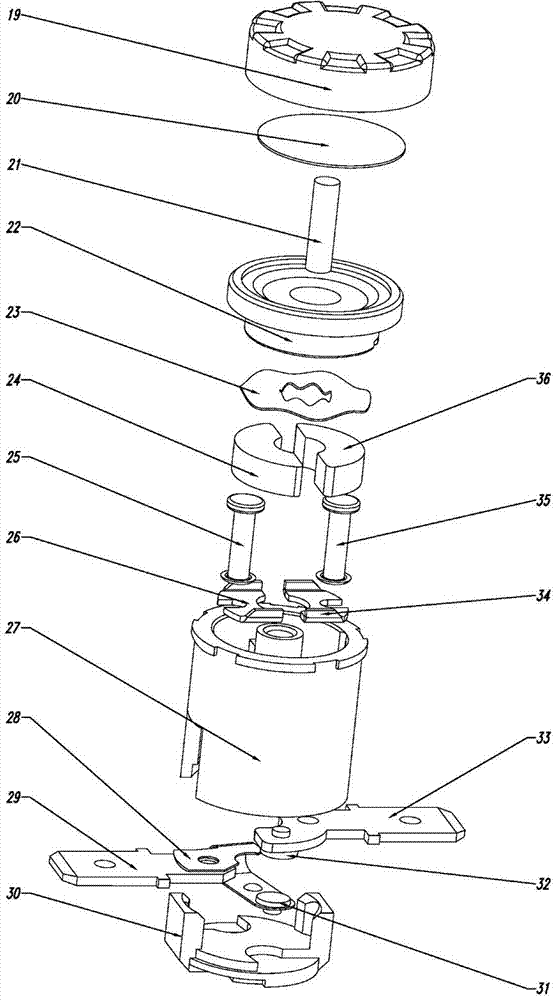

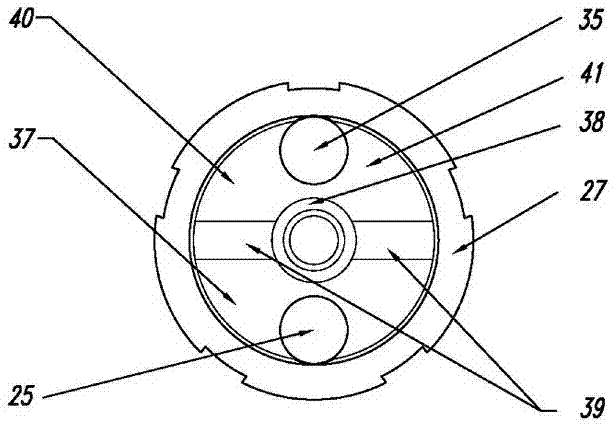

[0020] see Figure 2-Figure 5As shown, a short-circuit-proof power-off reset type jump-type thermostat consists of a cover 19, a bimetallic disc 20, an action rod 21, a guide frame 22, a sheet-shaped compression spring 23, and the first PTC to generate heat from top to bottom. body 24, the second PTC heating element 36, the first rivet 25, the second rivet 35, the first pressing block 26, the second pressing block 34, the shell 27, the first terminal 29, the reed 28, the moving contact 31, the fixed The contact 32, the second terminal 33 and the cover plate 30 are composed. The second terminal 33 and the fixed contact 32 riveted on the second terminal 33 form a fixed contact assembly. The reed 28 and the movable contact 31 form a movable contact assembly. The reed 28 has a structure of upper and lower layers formed by bending, and the movable contact 31 is riveted on the lower layer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com