Chip stripping device and system and device for controlling chip stripping

A technology for stripping devices and wafers, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc. It can solve problems such as high production costs and damage to wafer quality, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

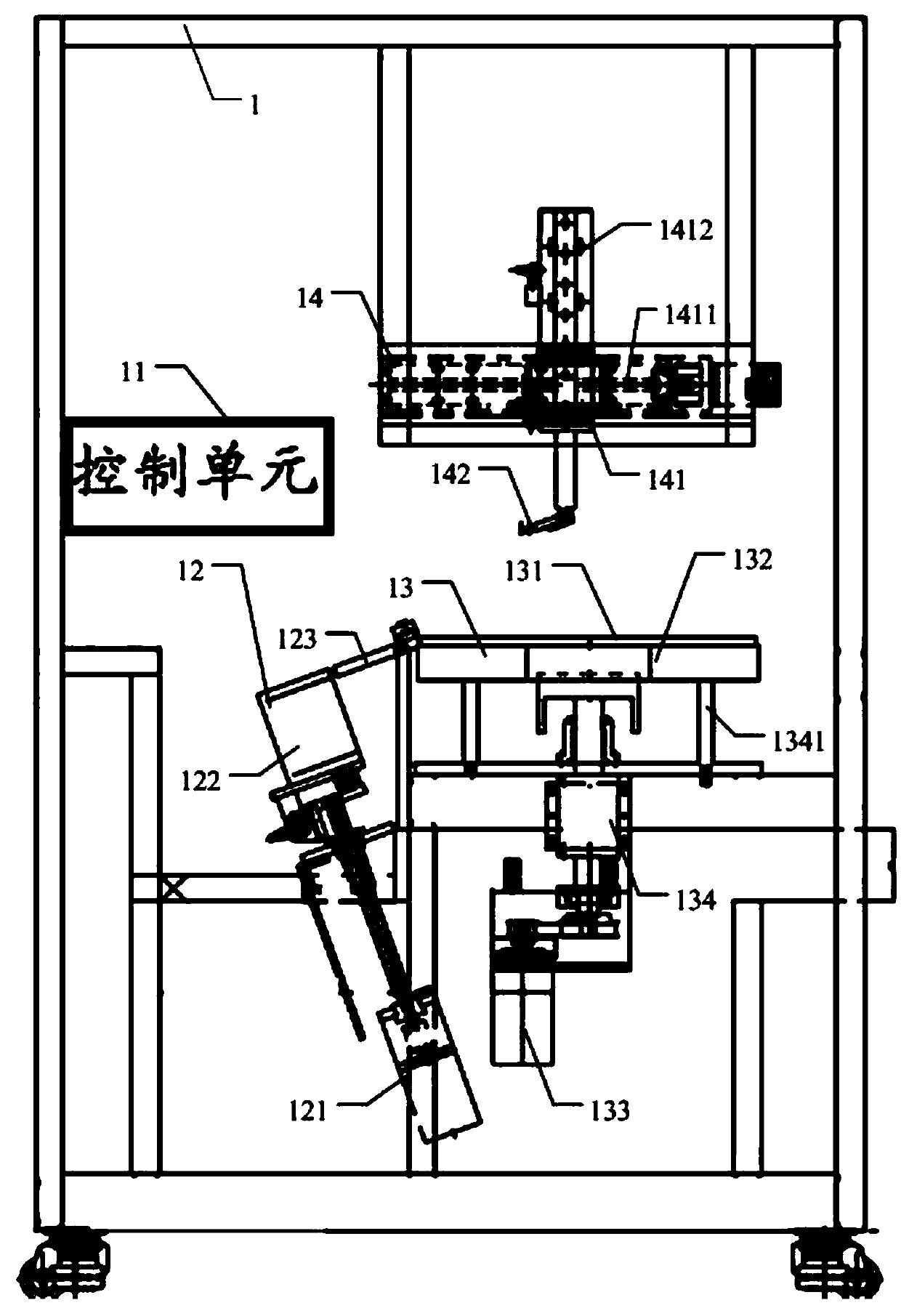

[0065] see figure 1 , the first embodiment of a wafer peeling device provided by the embodiment of the present invention includes:

[0066] Control unit 11, wafer pick-up unit 12, heating unit 13 and stripping unit 14, control unit 11 is connected with wafer pick-up unit 12, heating unit 13 and stripping unit 14 by connecting wire, control unit 11 is used for sending control command, wafer pick-up The unit 12, the heating unit 13 and the peeling unit 14 perform operations corresponding to the control instructions;

[0067] It can be understood that, the wafer peeling process of a wafer peeling device 1 provided in the embodiment of the present invention may be that the control unit 11 controls the heating unit 13 to heat the wafer, and when the wafer heating is completed, the control unit 11 controls the peeling unit 14 to The wafers on the heating unit 13 are transferred to the wafer transfer unit 12 .

[0068] It must be noted that the aforementioned wafer stripping proces...

no. 3 example

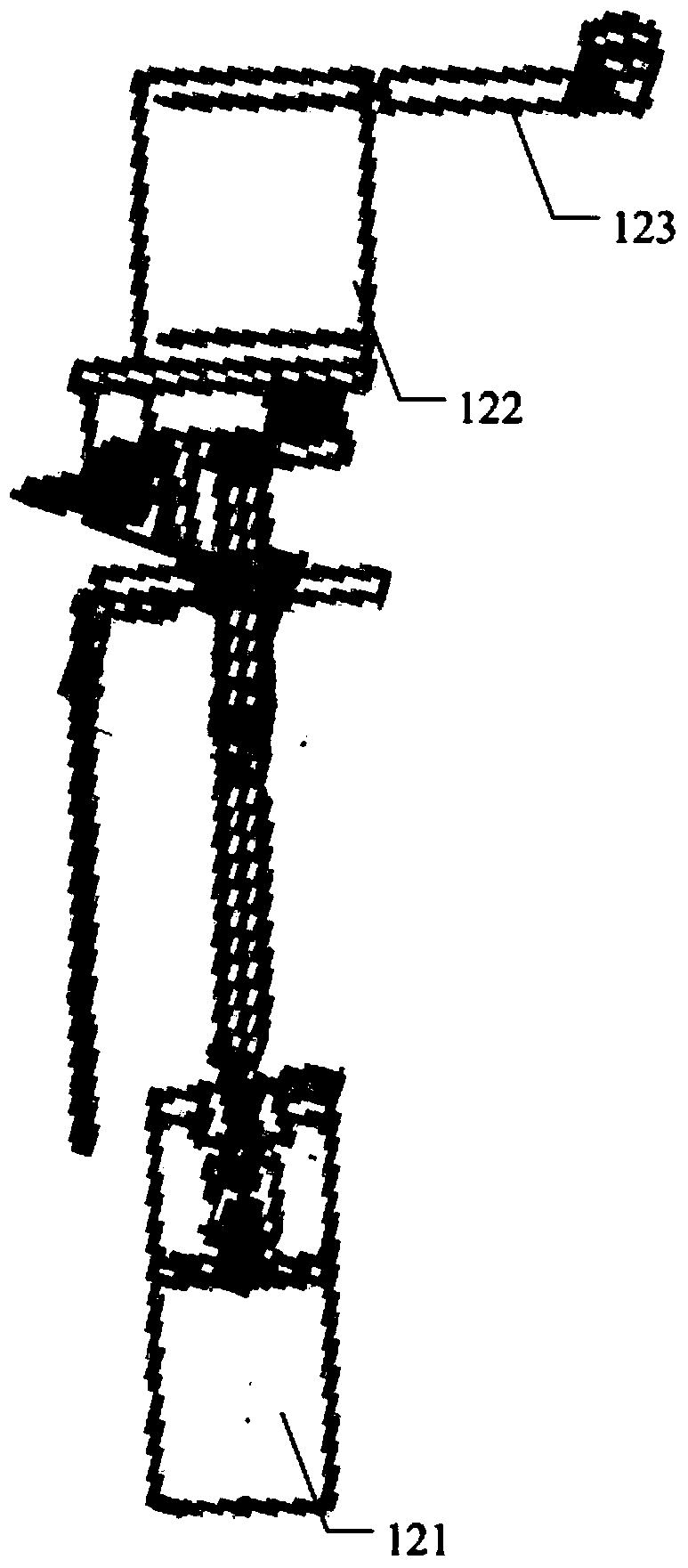

[0079] see figure 1 with image 3 , a third embodiment of a wafer peeling device provided in an embodiment of the present invention includes:

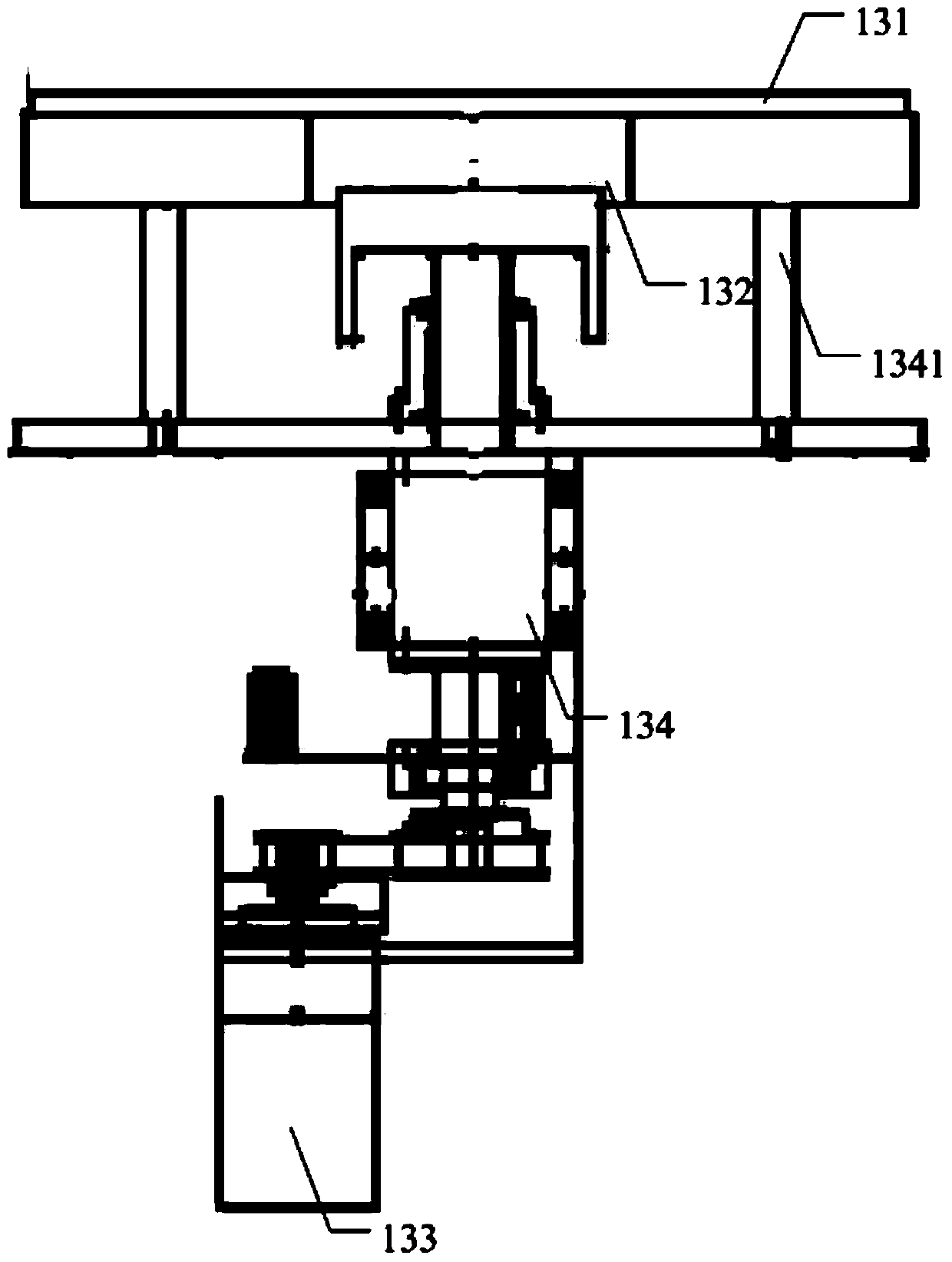

[0080] As mentioned above, the heating unit 13 includes a ceramic disc 131, a heating component 132, a second motor 133 and a rotating component 134. The heating component 132 is installed at the bottom of the ceramic disc 131. It should be noted that there is a groove in the middle of the ceramic disc 131, so that the heating component 132 During the heating process, heating is carried out from the middle of the ceramic plate 131 to the outer edge. The heating part 132 is a heat conduction shell with an electric heating wire installed inside. The heat conduction shell is a semi-closed ceramic aluminum alloy shell. In the aluminum alloy casing, the second motor 133 is connected to the rotating part 134, and is used to rotate the rotating part 134 in the horizontal direction by 360° through electric energy. The rotating part 134 also i...

no. 4 example

[0082] The specific structure of the stripping unit 14 and the process in which the stripping unit 14 performs wafer stripping according to the preset stripping mode will be described in detail below, please refer to figure 1 with Figure 4 , the fourth embodiment of a wafer peeling device provided by an embodiment of the present invention includes:

[0083] Aforesaid stripping unit 14 comprises: moving subunit 141 and blade 142, and moving subunit 141 comprises horizontal operating arm 1411 and vertical operating arm 1412, and horizontal operating arm 1411 and vertical operating arm 1412 are connected in a cross shape, and the edge of blade 142 is The tooth structure is installed on the bottom of the vertical operating arm 1412. The material of the aforementioned blade 142 can be resin material. It must be noted that the blade 142 is connected to the vertical operating arm 1412 at a certain angle, and the angle can be greater than 90° For example, when a plurality of wafers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com